jiangte insulation composite |

|

Verified Suppliers

|

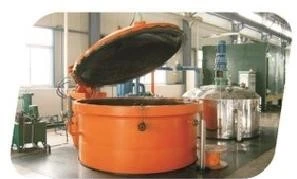

| NO | Model | Dryer size mm | Condenser | Vacuum unit | Heating system | Cooling system | Control mode | Open method |

| 1 | KBII-2400 | 2400X3000 | 4m² Horizontal 4m | 2X-70/ZJY-300 | Bumer + Heat transfer oil | Chiller | Touch screen | Laten Reemen |

| 2 | KBII-2600 | 2600X3500 | 4m² Horizontal 4m | X-100/ZJY-300 | Bumer + Heat transfer oil | Chiller | Touch screer | Latan Roement |

| 3 | KBII-2800 | 2800X3500 | 6m² Horizontal 6m | X-100/ZJY-300 | Bumer + Heat transfer oil | Chiller | Touch screen | Latera tp men |

| 4 | KBII-3000 | 3000X4000 | 6m² Horizontal 6m | X-100/ZJY-300 | Bumer + Heat transter oi | Chiller | Touch screen | Latei Raaenen |

| 5 | KBI-3200 | 3200X4000 | 6m² Horizontal 6m | X-150/ZJY-300 | Bumer + Heat transfer oi | Chiller | Touch screen | Laleral Repaeement |