7 -5/8 Standard Cementing Plug For Well Cementing,Oil Rig Equipment,

Drilling Special Tools Cementing Plug

Performance features

› Non-rotational.

› Decrease drill out time.

› PDC drillable.

Options

› Available in sizes from 4-1/2" to 20".

› Available in NR, SBR, NBR and HNBR grades.

ADVANTAGES AND MAIN FEATURES

Non-rotating cementing plugs are designed to decrease the drill out

times. Reinforced locking teeth are

built into the plugs, which lock together between the plug and the

float equipment to eliminate rotation

of the plug during drill out. The top cementing plug are latched to

the anti-rotational float collar.

Cementing plugs are used to remove the mud during cementing

operations.

Top cementing plugs and bottom cementing plugs are used in the

cementing process. The top and bottom

cementing plus general have different colors (bottom plugs are red

and top plugs are black) in

production for easy usage in operation.

The top cementing plug has a solid body that provides positive

indication of contact with

cementing floating collar and bottom plug through an increase in

pump pressure.

The bottom cementing plug with a hollow body is installed ahead of

the cement slurry to

minimize contamination by fluids inside the casing prior to

cementing.

Non-Rotary Cementing/Wiper Plugs (Polyurethane)

This plug is used to separate the cement slurry from other fluids,

reduce contamination, and maintain predictable slurry

performance and to clean various waste in the wall of the casing.

Two types of cementing plugs are typically used on a cementing

operation. The bottom plug is launched ahead of the cement slurry

to minimize contamination by fluids inside the casing prior to

cementing. A diaphragm in the plug body ruptures under 250~400psi

easily to allow the cement slurry to pass through after the plug

reaches the landing collar. The top plug has a solid body that

provides positive indication of contact with the landing collar and

bottom plug through an increase in pump pressure. This plug is

tested strictly every batch by pressure chambers at different

required pressure and temperature.

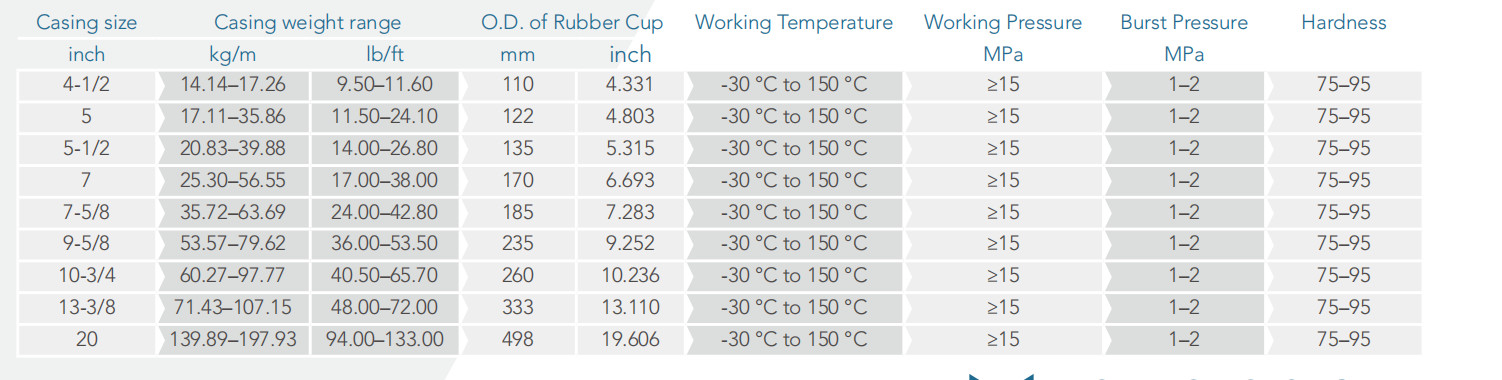

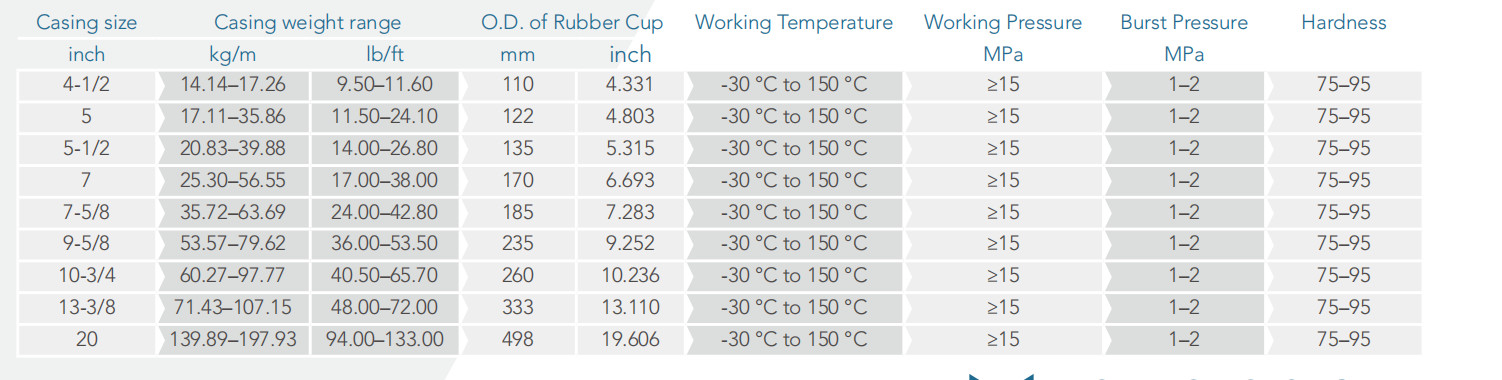

| Casig size inch | Casing weight range | O.D. of rubber cup | Working Temperature | Working pressure mpa | burst pressure mpa | hardness | | 4-1/2. | 14.14-17.26 kg/m | 9.5-11.6 lb/ft | 110mm | 4.331inch | (-30℃-150℃) | ≥15mpa | 1-2mpa | 75-95 | | 5 | 17.11-35.86 kg/m | 11.5-24.1 lb/ft | 122mm | 2.803inch | (-30℃-150℃) | ≥15mpa | 1-2mpa | 75-95 | | 5-1/2. | 20.83-39.88 | 14-26.8 | 135 | 5.315 | (-30℃-150℃) | ≥15mpa | 1-2mpa | 75-95 | | 7 | 25.3-56.55 | 17-28 | 170 | 6.693 | (-30℃-150℃) | ≥15mpa | 1-2mpa | 75-95 | | 7-5/8. | 35.72-63.69 | 24-42.8 | 185 | 7.283 | (-30℃-150℃) | ≥15mpa | 1-2mpa | 75-95 | | 9-5/8. | 53.57-79.62 | 36-53.5 | 235 | 9.252 | (-30℃-150℃) | ≥15mpa | 1-2mpa | 75-95 | | 10-3/4. | 60.27-97.77 | 40.5-65.7 | 260 | 10.236 | (-30℃-150℃) | ≥15mpa | 1-2mpa | 75-95 | | 13-3/8. | 71.43-107.15 | 48-72 | 333 | 13.110 | (-30℃-150℃) | ≥15mpa | 1-2mpa | 75-95 | | 20 | 139.89-197.93 | 94-133 | 498 | 19.606 | (-30℃-150℃) | ≥15mpa | 1-2mpa | 75-95 |

|

Q1. How to get an accurate quotation?

A1: The customer should provide the related technical requirements,

drawings, pictures, industrial voltage, planned output,

Q2. What if I use this machine for the first time and know nothing

of it ?

A2: We will have our engineers teach you how to operate it,you can

just inform us some details of the product you need then we can

customize as your special order.

Q3. How does your factory do regarding quality control?

A3: We has been regard quality as the priority. We always attach

great importance to quality controlling from the very beginning to

the very end ,so our press can match all the CE and ISO standard

also more strict standard .

Q4. How about your delivery time?

A4: Generally, it will take 35 working days after receiving your

deposit payment. The specific delivery time depends on the items

and the quantity of your order. Sometimes we have standard machines

in stock.

Q5. What is the warrantee period of the machine?

A5: We can supply 1 year warranty for our machines, We can send

engineer to customer place if big quality problem. We can provide

internet or calling service at any time.

Q6. after-sales service

A6: 1. Installation:Free installation and commissioning, travel

expense is on foreign customer.(Including round ticket and

accommodation cost)

2. Personnel training: Our engineers will give your employees free

machine training when they come to your company to assemble the

machines, and welcome to our factory to learn how to operate our

machineQ1. How to get an accurate quotation?.