CHANGZHOU JKONGMOTOR CO.,LTD |

|

Verified Suppliers

|

|

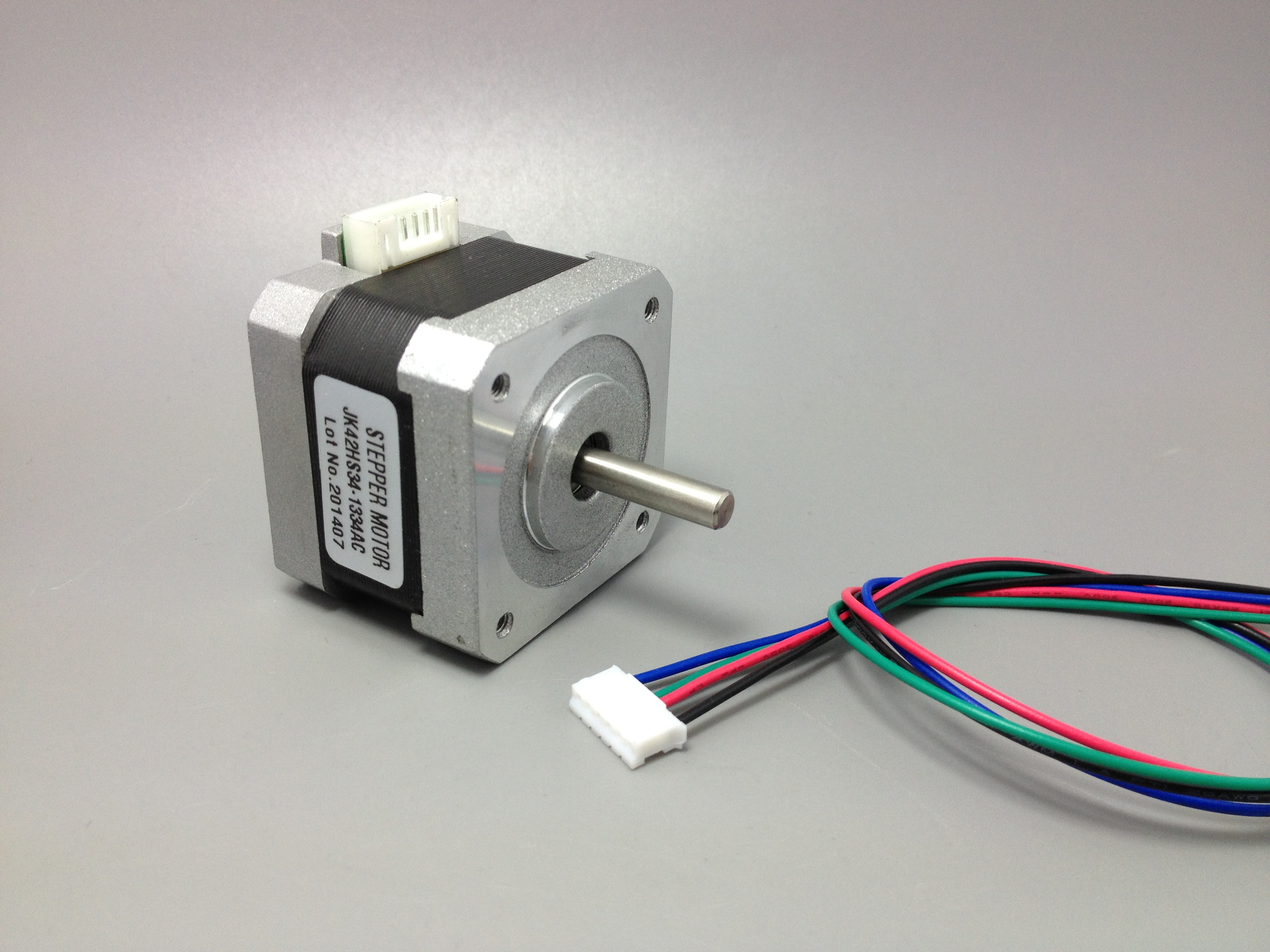

42HS Series Stepping Motor NEMA 17 High Torque 37OZ.IN 24V Height 34mm With Black Endcap

The combination of two motors like a permanent magnet and variable reluctance is known as a hybrid motor. The working principle of a hybrid motor is, the rotor in this motor is magnetized axially similar to a permanent magnet stepper motor, whereas the stator is energized electromagnetically similar to a variable reluctance stepper motor. So it is an actuator that changes electrical pulses to angular displacement.

1.Electrical Specification:

| Model No. | Step Angle | Motor Length | Current /Phase | Resistance /Phase | Inductance /Phase | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | kg.cm | No. | g.cm | g.cm | Kg | |

| JK42HS34-1334AC-01 | 1.8 | 34 | 1.33 | 2.1 | 2.5 | 2.6 | 4 | 120 | 34 | 0.22 |

2.Genaral Specification:

| Item | Specifications |

| Step Angle | 1.8° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 28N (20mm from the flange) |

| Max. axial force | 10N |

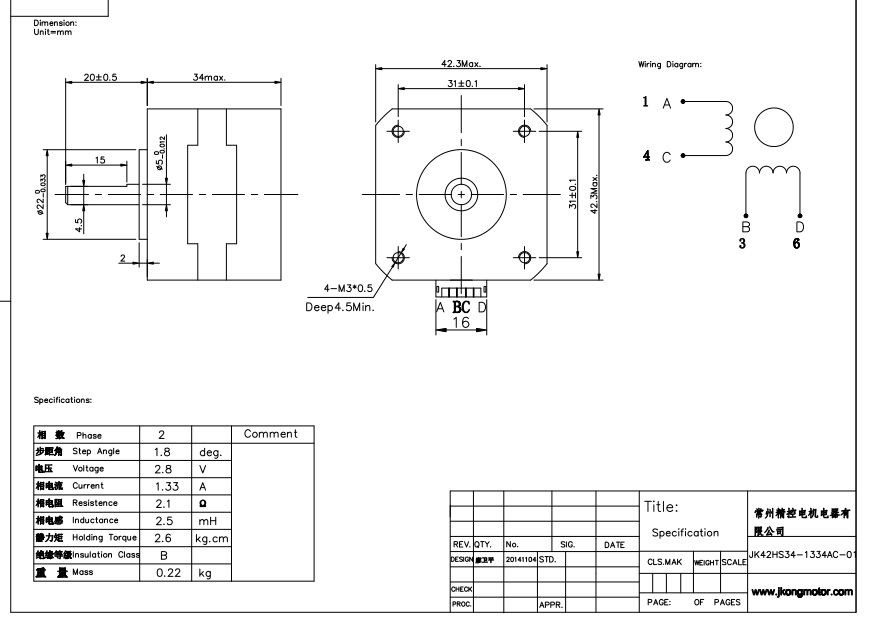

3.Drawing

4.Stepper motor angle

Stepper motors for 3D printers require a step angle of 1.8°.

There are 200 steps in one rotation, because 1.8° x 200=360°, you can choose a smaller angle and more precise.

But if the angle is larger, it needs to be used with the speed reduction gear.

5.Current and power

When selecting a stepper motor, pay attention to the rated voltage and current parameters.

As long as the stepper motor drive power can control the current output, it is theoretically possible to use any supply voltage higher than the rated voltage of the motor.

If the drive power cannot control the current, you need to use a supply voltage close to the rated voltage, otherwise the motor will be at risk of overheating.

Stepper Motor Advantages

Computer controlled stepper motors are a type of motion-control positioning system. They are typically digitally controlled as part of an open loop system for use in holding or positioning applications.

In the field of lasers and optics they are frequently used in precision positioning equipment such as linear actuators, linear stages, rotation stages, goniometers, and mirror mounts. Other uses are in packaging machinery, and positioning of valve pilot stages for fluid control systems.

Commercially, stepper motors are used in floppy disk drives, flatbed scanners, computer printers, plotters, slot machines, image scanners, compact disc drives, intelligent lighting, camera lenses, CNC machines and, more recently, in 3D printers.