Our customers are all around the world.

Vietnam, Australia, Indonesia, Malaysia, Thailand, Sri Lanka,

Kazakhstan, Russia, UAE, Saudi Arabia, Malta, Romania, Italy,

India, Syria, Ethiopia, Egypt, Sudan, Tunisia, Algeria, Kenya, Nigeria,

South Africa, Zimbabwe, Mexico, Guatemala, Ecuador, Colombia, Venezuela, Peru....

We have our own service team in

Saudi Arabia, Colombia, Panama, South Africa ...

DAWSON MACHINE & MOULD GROUP

located in Zhangjiagang city, have more than 18 years' experience

in the field of plastic machinery,

injection molding machine, blow molding machine, PET blow molding machine, injection blow

molding machine, during the past 18 years, we always force our energy into new areas of plastic machinery, plastic packaging

machinery, to update the technology, to learn advanced experience,

to confirm new theory and new design, we are forming a unique

competitive advantage of our owns.

The machines from our company carry good quality and effective

after-sales service, upon the market,

customers from more than 45 countries, we provide complete solution for your plastic industry

business, as well as all sorts of technical support &

after-sale services!

DAWSON will be your reliable friend in China, and we will always do

our best to give you max support!

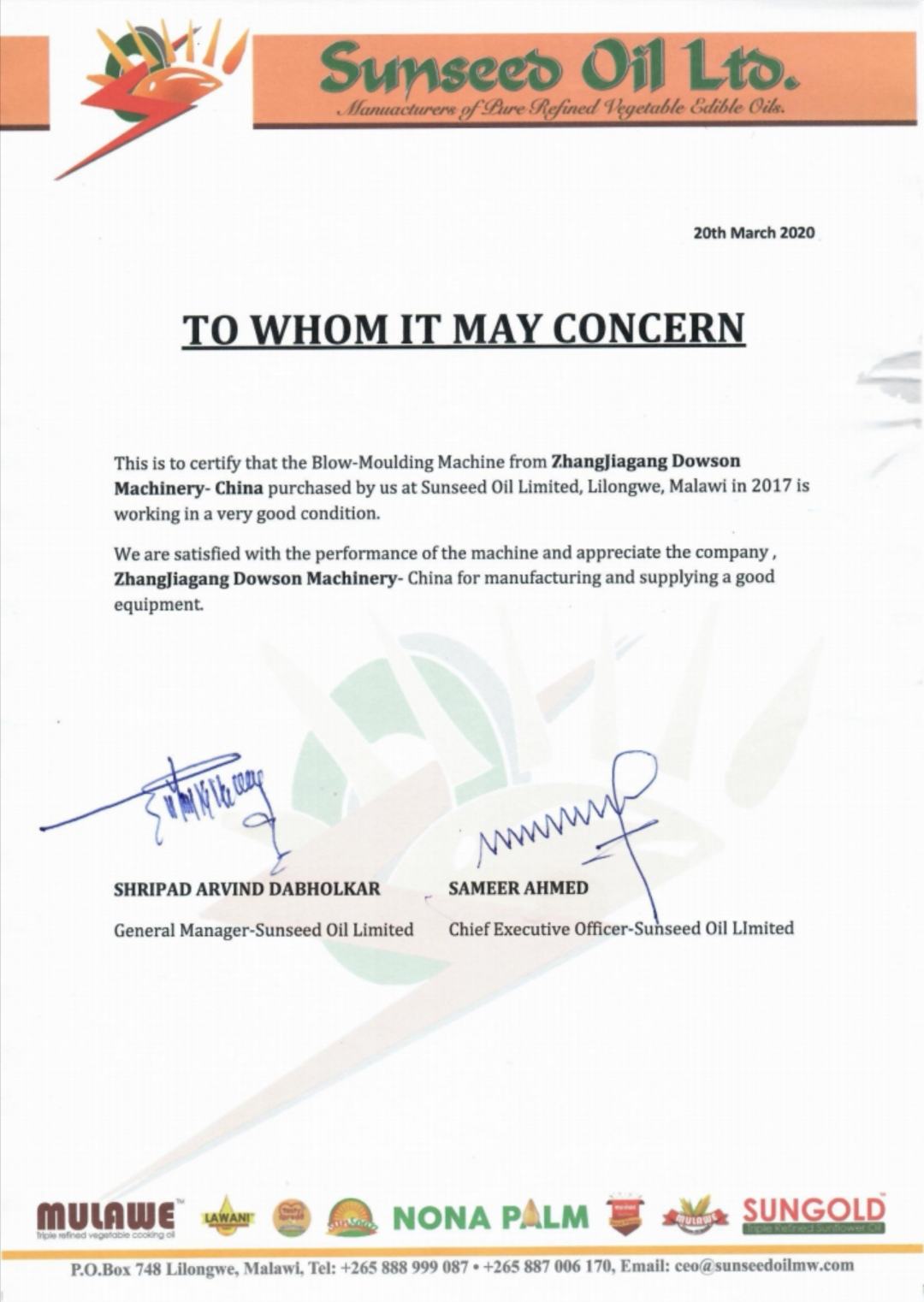

Customer Photos

We committed to providing customers with plastic machinery &

equipment production lines beyond expectations.

Customer satisfaction is our eternal pursuit...

|

Q: Can we visit your factory?

Sure. We located in Zhangjiagang city which is very near Shanghai.

For overseas customers, you can fly to Shanghai Pudong

International Airport. We can

pick you up in the Airport. (or Hongqiao International Airport. )

We also provide visit online by video.

Q: How can we get the exact price of plastic machine?

Contact us with the products size, shape, annual quantity and photo

if possible. We can recommend our machine models with quotation.

Q: Do you provide any spare parts with machine?

Yes, we offer all necessary spare parts before shipment.(contact us

for packing list )

Q: How about your after-sale service ?

We offer manual instruction and engineer training before

loading,after shipment we provide 24 HRS online support, video

technical support or field installation assist.

Q: What is the lead time?

For customized machine, it takes about 45-50 days after deposit. For stock machine, fast shipment. ( The actual

production cycle will vary according to the degree of

customization.)

Q: What is the warranty period for your machine ?

12 months warranty for components and technical support .

Q: Do you provide custom machines?

Most of our machines are customized. Our goal is efficiency and

stable performance. We design the machines according to customers

products to meet customer' needs.

Q: How can we install the machine when it arrives?

We can send experienced technicians to customer's country for

guiding the installation and commission the machine, also train the

customer's employees.

Q: What's DAWSON's advantage?

DAWSON provide customers with turnkey projects. Including plant

design, plastic machine and mold installation, debugging, also we

can source the auxiliary equipment for customers. We can ship the

full set of machines after testing in our factory. It will save a

lot of cost and time.

DAWSON will be your reliable friend in China, and we will always do

our best to give you max support!

|