Wuxi Yushun Metallurgical Technology Co., Ltd. |

|

Verified Suppliers

|

|

Continuous Automatic High Speed Wire Production Line with Annual Output of 500,000 Tons

The whole process for continuous automatic production, the production technology and equipment is mature and reliable, with the domestic advanced level. There are total of 28 rolling mills in the whole line. Rough and medium rolling mills 1# to 14# adopt grooveless rolling, with the maximum rolling speed of 80m/s. Cooling control system, Stellmore coil cooling control system and optical caliper have played an important role in improving the dimensional accuracy and quality of products.

The annual production capacity of this production line is 500,000 tons, the main products are hot rolled smooth round steel bar, construction thread steel bar (coil), plain carbon steel bar and high quality carbon steel bar.

Main product type:

| No. | Product type | Standard | Steel grade | Specification T*W(mm) |

| 1. | Hot rolled ribbed bar | GB/T1499.2-2018 | HRB400,HRB400E | 8-12 |

| 2. | Hot rolled smooth round steel bar | GB/T3274-2017 CQGTJX050-2019-1 CQGTJX057-2019-1 CQGTJX008-2019-1 | HPB300 | Ø6.5-Ø12 |

| 3. | Low carbon steel hot rolled round wire rod | GB/T701-2008

| Q215,Q235 | Ø6.5-Ø10 |

| 4. | High quality carbon steel hot rolled wire rod | CQGTJX190-2019-01

| 45,60,65,70,75,80,65C,70C,75C | Ø6.5-Ø10 |

Main equipment of high speed wire rod coil production line:

| 1. | 610-350 horizontal and vertical short stress path rolling mill |

| 2. | 550-350 2-hi roll horizontal and vertical closed rolling mill |

| 3. | Crops (chopping)shear |

| 4. | Water cooling equipment |

| 5. | 285 cantilevel type pre-finishing mill group |

| 6. | 10 rack 45°no-twist high speed and heavy load finishing mill group |

| 7. | Pinch roll |

| 8. | Laying head |

| 9. | Air cooling control cooling line |

| 10. | Coil collecting station |

| 11. | P/F cooling line |

| 12. | Full- automatic wire rod packer |

Features:

| 1. | High dimensional accuracy, small ellipticity |

| 2. | Using distributed wind cooling, its composition is uniform, good mechanical properties |

| 3. | Because of negative tolerance rolling, it saves metal, and the high speed wire is longer than the normal wire for the same weight |

| 4. | Each piece has only one head and tail |

| 5. | The high speed wire is 20~40 yuan /t more expensive than the general wire |

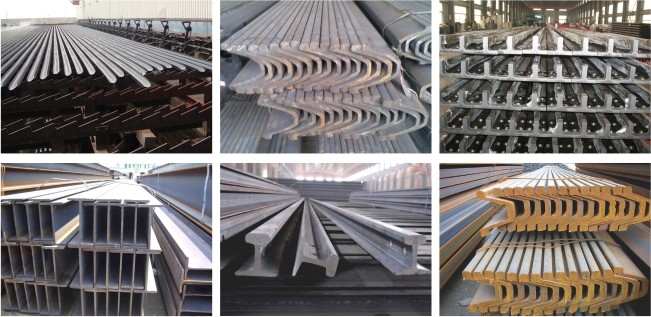

Our company can design and manufacture section steel rolling equipment including short-stress path, universal rolling mill. Specification: 750,850,950,1150. Our company can contract the turn-key project for this kind of project, the investment of which is small but the performance is good. |

Packaging Details: Wooden case packing or nude packing

Port: Tianjin

Lead Time:

| Quantity(Sets) | 1-1 | >1 |

| Est.Time(Days) | 30 | To be negotiated |

Recommed Products

Rolling mill is a mill or factory where ingots of heated metal are passed between rollers to produce

sheets or bars of a required cross section and form.

We supply the whole production lines, from induction furnace, CCM to rolling mills, cooling beds

and packing. Our hot rolling mill can produce 8-32mm deformed rebar, round bar and also wire

rod.

Technology Parameter

| Production capacity: | 50,000MT-800,000MT/year |

| Type of steel: | Quality carbon steel, low alloy steel, etc. |

| Material: | Billet size from 80mm*80mm to 150mm*150mm |

| Final products: | Φ5.5-Φ12mm wire rod, Φ8-Φ40mm rebar |