Wuxi Yushun Metallurgical Technology Co., Ltd. |

|

Verified Suppliers

|

|

ISO 9001 Block Mill Wire Rod Mills Main Drive Gear Box Short Stress Rolling Mill

Used for driving horizontal and vertical rolling mills;Reducer box is welded steel plate after elimination of welding stress treatment, all gears are hard tooth surface, carburizing, quenching, tooth surface hardness HRC57-61, gear accuracy of national standard grade 6;Gear material 20CrNi2MoA.The transmission case is lubricated by concentrated thin oil.Reducer in the prime mover and working machine or actuator to match speed and transfer torque between the role, is a relatively precise machinery.The purpose of using it is to reduce speed and increase torque.It has a wide variety of models, different types have different uses.There are many kinds of reducer, according to the transmission type can be divided into gear reducer, worm reducer and planetary gear reducer;According to the different transmission series can be divided into single stage and multistage reducer;According to the gear shape can be divided into cylindrical gear reducer, bevel gear reducer and bevel - cylindrical gear reducer;According to the arrangement of transmission form can be divided into expansion type, shunt type and coaxial reducer.

| Condition: | New |

| Type: | Steel rolling mill |

| Warranty of core components: | 1 Year |

| Core components: | Bearing, Gearbox, Motor, Gear |

| Voltage: | Customized |

| Power: | Customized |

| Dimension(L*W*H) | Customized |

| Specification: | 750,850,950,1150 |

| Certification: | ISO 9001 |

| Output: | Negotiated |

| After-sales-Service Provided: | Video technical support, online support |

| Applicable industries: | Manufacturing plant, construction works |

| Raw material: | Steel product |

| Usage: | Steel construction |

| Item: | Finishing |

| Color: | Customized |

| Finished product: | Steel |

Our company can design and manufacture section steel rolling equipment including short-stress path, universal rolling mill. Specification: 750,850,950,1150. Our company can contract the turn-key project for this kind of project, the investment of which is small but the performance is good. |

Packaging Details: Wooden case packing or nude packing

Port: Tianjin

Lead Time:

| Quantity(Sets) | 1-1 | >1 |

| Est.Time(Days) | 30 | To be negotiated |

Recommed Products

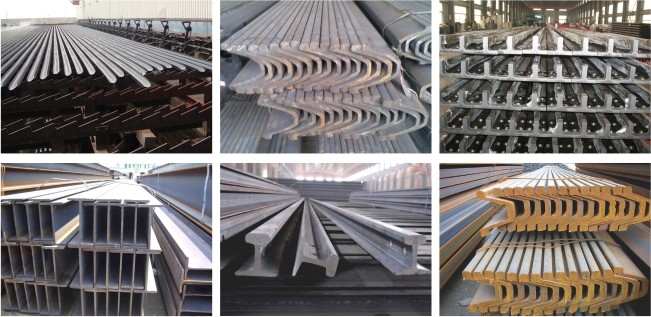

Rolling mill is a mill or factory where ingots of heated metal are passed between rollers to produce

sheets or bars of a required cross section and form.

We supply the whole production lines, from induction furnace, CCM to rolling mills, cooling beds

and packing. Our hot rolling mill can produce 8-32mm deformed rebar, round bar and also wire

rod.

Technology Parameter

| Production capacity: | 50,000MT-800,000MT/year |

| Type of steel: | Quality carbon steel, low alloy steel, etc. |

| Material: | Billet size from 80mm*80mm to 150mm*150mm |

| Final products: | Φ5.5-Φ12mm wire rod, Φ8-Φ40mm rebar |