Dongguan Quality Control Technology Co., Ltd. |

|

Automatic Rockwell Hardness Testing Machine Twin Electronic Hardness Tester With Touch Screen

Technical Data Download: iqualitrol Rockwell Hardness Tester iRock-439T

Operation Manual Download: iqualitrol iRock-439T Operation Manual

Brief Introduction:

iRock-439T Automatic twin Rockwell hardness tester with a good aesthetic aspect, complete functions, easy operation, intuitive display and good reliability, is a high-tech product combining the mechanic and electric features, which is suitable to test Rockwell and superficial Rockwell hardness test.

Main features:

1. Support Rockwell and superficial Rockwell scales;

2. Support hardness conversion;

3. Touch screen dynamically display the working state of the

lifting screw and the indenter;

4. Press operation for the test table, fast rising or declining;

5. One key to complete the rising of the specimen, loading dwell

and unloading of the indenter, displaying of the hardness value,

homing of the test table;

6. With data storage function, automatic calculation of the

maximum, minimum, average of the hardness value, the test results

can be printed for output, and with a RS232 interface users can

connect it to the computer for output.

Application range:

Suitable for quenched steel, tempered steel, annealed steel, cold

and hard casting, malleable cast iron, hard alloy steel, aluminum

alloy, copper alloy, bearing steel etc. Also suitable for surface

quenched steel, surface heat treating and chemical treating

materials, sheet, zinc layers, chrome layers, tin layers etc.

Technical Specification:

| Model | iRock-439T |

| Initial Test Force | 3kgf (29.42N), 10kgf (98.07N) |

| Total Test Force | 15kgf (147.1N), 30kgf (294.2N), 45kgf (441.3N), |

| Indenter | Diamond Rockwell Indenter, ф1.588mmBall Indenter |

| Loading Method | Automatic (Loading/Dwell/Unloading) |

| Automatic Test Table | Automatic lifting system, One Key to Complete |

| Hardness Reading | Touch Screen |

| Test Scale | HRA, HRD, HRC, HRF, HRB, HRG, HRH, HRE, HRK, HRL, HRM, HRP, HRR,

HRS, HRV |

| Conversion Scale | HV, HK, HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRK, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HBW |

| Data Output | RS232 Interface |

| Resolution | 0.1HR |

| Dwell Time | 0~99s |

| Vertical Space | 320mm |

| Throat | 150mm |

| Power Supply | AC220V/50Hz/1Ph |

| Execute Standard | ISO 6508, ASTM E-18, JIS Z2245, GB/T 230.2 |

| Dimension | 535×330×890mm, Packing Dimension: 820×460×1170mm |

| Weight | Net Weight: 80kg, Gross Weight: 100kg |

Packing List:

| Name | Qty | Name | Qty |

| Instrument Main Body | 1 set | Diamond Rockwell Indenter | 1 pc |

| ф1.588mmBall Indenter | 1 pc | Middle Plane Test Table | 1 pc |

| Large Plane Test Table | 1 pc | V-shaped Test Table | 1 pc |

| Hardness Block 60~70 HRC | 1 pc | Hardness Block 20~30 HRC | 1 pc |

| Hardness Block 80~100 HRB | 1 pc | Hardness Block70~85 HR30T | 1 pc |

| Hardness Block 65~80 HR30N | 1 pc | Fuse 2A | 2 pcs |

| Power Cable | 1 pc | Anti-dust Cover | 1 pc |

| Usage Instruction Manual | 1 copy |

The Rockwell test consists of measuring the additional depth to which a carbide ball or diamond penetrator is forced by a heavy (major) load beyond the depth of a previously applied light (minor) load (SET point).

The minor load is applied first and a SET position is established on the dial gauge or displacement sensor of the Rockwell tester. Then the major load is applied. Without moving the piece being tested, the major load is removed and, with the minor load still applied, the Rockwell hardness number is automatically indicated on the dial gauge or digital display.

The diamond penetrator is used for testing materials such as hardened steels and cemented carbides. The carbide ball penetrators, available with 1/16 inch, 1/8 inch, 1/4 inch, and 1/2 inch diameter, are used when testing materials such as steel-copper alloys, aluminum and plastics to name a few.

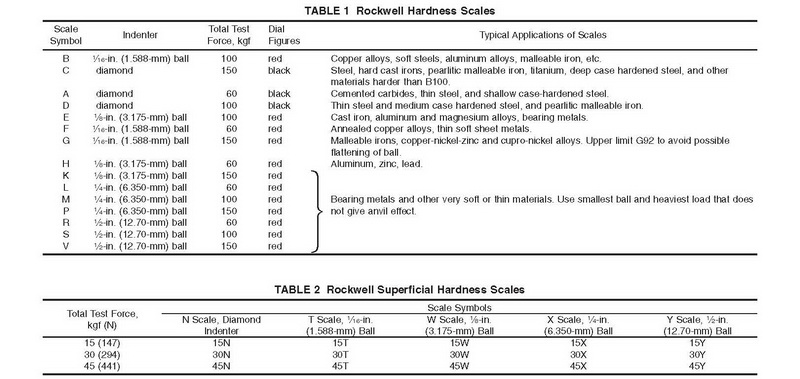

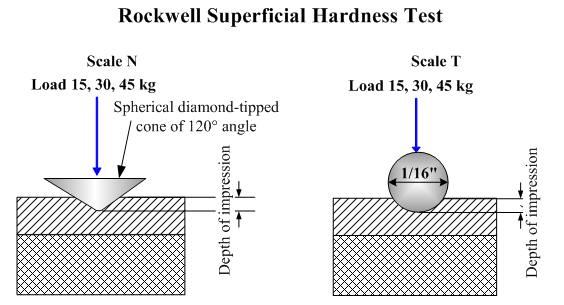

Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and

Rockwell superficial testing (e.g., 30 N and 30 T scales).

High Rockwell hardness numbers represent hard materials and low numbers soft materials.