Guangzhou Andea Electronics Technology Co., Ltd. |

|

Verified Suppliers

|

|

Micro Power split designed HF rfid card reader Modbus TCP/IP Communication with TNC and M12 interface

Quick detail of RFID Card Reader:

Support Standard:ISO15693,ISO14443 TypeA/B;

Communication Interface:TNC(F) + M12D(4pin M) ;

Communication mode:Modbus TCP;

Waterproof/ dustproof:IP67;

Fixed type:4*M4 screw;

Specification of RFID Card Reader:

| Specification | |

| Support Standard | ISO15693,ISO14443 TypeA/B |

| Operating Frequency | 13.56MHz |

| Reading Range | 0-100mm |

| Communication mode | Modbus TCP |

| Communication rate | 10/100M bps |

| Power Supply | 48V POE(46-54V), 24V DC(9~30V) |

| Current | <0.04A@24V DC |

| Physical parameters | |

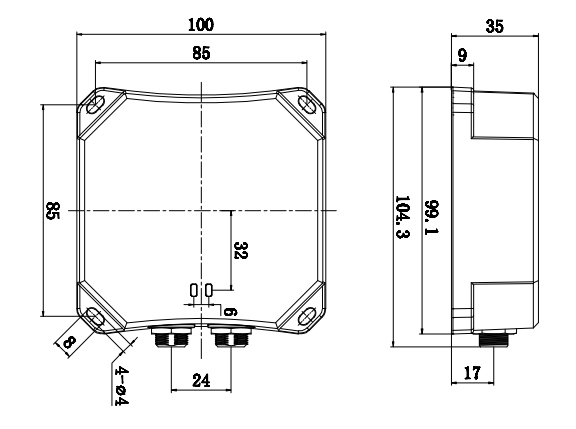

| Dimension | 100*100*35mm |

| Weight | 160g |

| Fixed type | 4*M4 screw |

| Housing Material | ABS and Metal plate |

| Color | Black |

| Indicator light | LED*2 |

| Interface | TNC(F) + M12D(4pin M) |

| Application environment | |

| Working Temperature | -40℃~+85℃ |

| Humidity | 5%~95%RH |

| Waterproof/dustproof | IP67 |

Advantages of RFID Card Reader:

One of the biggest benefits of RFID is ensuring the accuracy of build instructions in a manual assembly environment. Traditionally, work orders and build sheets must be updated at every workstation. With RFID, updates can be written to the tag so that it is constantly being updated without risk of operator error. That means critical tasks aren't skipped or executed incorrectly.

RFID Card Reader Application:

Distributed Production Line of Automotive Seats

installed RF tags on the bottom of seat pallets. As each seat progresses down the assembly line, the pallet passes over an antenna at each workstation. Operators reference a touchscreen PLC that indicates seat type as well as needed alterations.

If a seat requires work, the operating system won't let the seat continue down the line until the operator has made and verified all necessary adjustments. The antenna then writes to the tag, updating it with whatever modifications have been made to the seat.

The process continues until the seat reaches the final workstation where its build instructions are verified with the actual assembly record. If they match up, the seats are transferred to the shipping area and are sequenced for delivery to the automaker's assembly line.

RFID system allows operators to assemble many different types of seats on the same production line.

Warehouse RFID Forklift System

The carrier of forklift transportation of goods is mainly based on pallets. The forklift management system using RFID technology consists of an RFID reading system by installing UHF RFID readers, UHF RFID antennas and industrial control computers on the forklift. By using RFID tags on finished pallets, when forklifts equipped with RFID reading systems pick up pallets, they can obtain RFID tag data to confirm cargo information and complete the uninterrupted tracking of finished product information. The precise management of goods in and out of warehouses, goods transfers, and cargo locations provides basic information protection.

Dimension Drawing(mm):

Installation Instruction:

This reader use four M4 screws to fixing. According to the installation environment of the site,we can support bracket to install.If there has Metal plate beside the product,please make sure that the distance between reader and Metal plate has more than 15mm,or it will influence the performance of reading and writing.

When there are more than two readers to be installed, the distance between the readers needs to be greater than 850mm.