Guangzhou Andea Electronics Technology Co., Ltd. |

|

Verified Suppliers

|

|

ISO 15693 Protocol TNC and M12D Interface RFID Industrial Reader Split Sesigned IP67

Quick detail of RFID Industrial Reader:

Operating Frequency13.56MHz;

Support Standard:ISO15693;

Communication Interface:TNC(F) + M12D(4pin M) ;

Communication mode:Modbus TCP;

Waterproof/ dustproof:IP67;

Reading Range0-140mm;

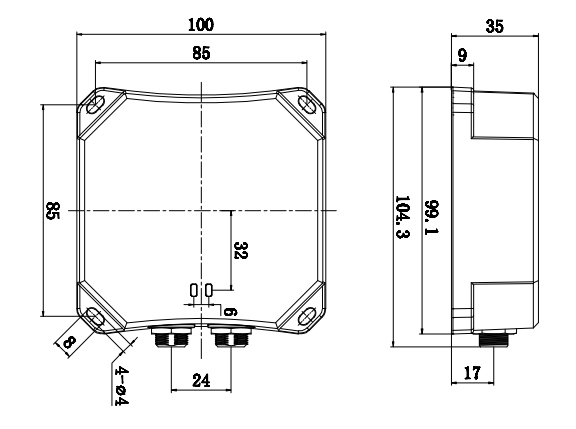

Dimension100*100*35mm;

Specification of RFID Industrial Reader:

| Specification | |

| Support Standard | ISO15693 |

| Operating Frequency | 13.56MHz |

| Reading Range | 0-140mm |

| Communication mode | Modbus TCP |

| Communication rate | 10/100M bps |

| Power Supply | 48V POE(46-54V), 24V DC(9~30V) |

| Current | <0.3A@24V DC |

| Physical parameters | |

| Dimension | 100*100*35mm |

| Weight | 160g |

| Fixed type | 4*M4 screw |

| Housing Material | ABS and Metal plate |

| Color | Black |

| Indicator light | LED*2 |

| Interface | TNC(F) + M12D(4pin M) |

| Application environment | |

| Working Temperature | -40℃~+85℃ |

| Humidity | 5%~95%RH |

| Waterproof/dustproof | IP67 |

Advantages of RFID Industrial Reader:

Reduces use of raw materials;

Less damage to moulds due to better control of resin injection;

Reduced energy use due to better control of curing process;

Data insights allow greater control over production and improved efficiency;

Excellent return on minimal investment;

RFID Industrial Reader Application:

Distributed Production Line of Automotive Seats

installed RF tags on the bottom of seat pallets. As each seat progresses down the assembly line, the pallet passes over an antenna at each workstation. Operators reference a touchscreen PLC that indicates seat type as well as needed alterations.

If a seat requires work, the operating system won't let the seat continue down the line until the operator has made and verified all necessary adjustments. The antenna then writes to the tag, updating it with whatever modifications have been made to the seat.

The process continues until the seat reaches the final workstation where its build instructions are verified with the actual assembly record. If they match up, the seats are transferred to the shipping area and are sequenced for delivery to the automaker's assembly line.

RFID system allows operators to assemble many different types of seats on the same production line.

Rapid checks ensure kit is on hand and safe to use

In any medical setting, keeping track of essential assets can be challenging. Take an ambulance crew on the move – under pressure of dealing with emergencies, equipment may be misplaced, exchanged with other crews or left in hospitals. Even if it is returned to the ambulance, it may be stowed in the wrong location and appear to be missing.

Technology can solve this problem. With RFID asset tracking systems, each item to be monitored is given its own RFID tag which carries a unique identifying number. Tags can be read by a handheld device which will recognise the item and link it to an online database that keeps a record of its whereabouts and use.

Using a handheld device, it is possible to take an immediate inventory of a vehicle or an area to check which items are present and which, if any, are missing. The device will identify the tags on board the vehicle, compare them with a list of items that ought to be in place, and identify any unexpected assets.

The data provides a complete up-to-date record, enabling personnel in any location to see what assets are where, and giving a history of their usage.

Dimension Drawing(mm):

Installation Instruction:

This reader use four M4 screws to fixing. According to the installation environment of the site,we can support bracket to install.If there has Metal plate beside the product,please make sure that the distance between reader and Metal plate has more than 15mm,or it will influence the performance of reading and writing.

When there are more than two readers to be installed, the distance between the readers needs to be greater than 850mm.