Guangzhou Andea Electronics Technology Co., Ltd. |

|

Verified Suppliers

|

|

RFID Antenna Installed On The Sewing Machine To Identify The Number Of Clothing Tags And Record The Working Time

RFID technology has been widely used in various industries, including the textile industry. By incorporating RFID tags into clothing items, manufacturers can easily track and manage inventory levels, monitor the movement of goods through production lines, and improve supply chain efficiency. However, integrating RFID technology into sewing machines can offer even more advantages.

An RFID antenna installed on a sewing machine can identify the number of clothing tags used during the manufacturing process and record the working time. This information can be used to improve production planning, optimize machine utilization, and reduce downtime. In addition, tracking the number of clothing tags used can provide valuable data for cost accounting and inventory control purposes.

To implement RFID technology into sewing machines, RFID reader modules and antennas must be installed on each machine. The RFID reader module communicates with the RFID tags on the clothing items and sends the data to a central database or system for processing. The antenna, on the other hand, captures the signals emitted by the RFID tags and delivers them to the reader module.

In summary, integrating RFID technology into sewing machines can offer numerous benefits for the textile industry, including improved production planning, optimized machine utilization, and better inventory control. By using RFID technology, manufacturers can increase efficiency, reduce costs, and enhance their competitiveness in the global marketplace.

| Specification | |

| Operating Frequency | 13.56MHz |

| Reading Range | 0-40mm |

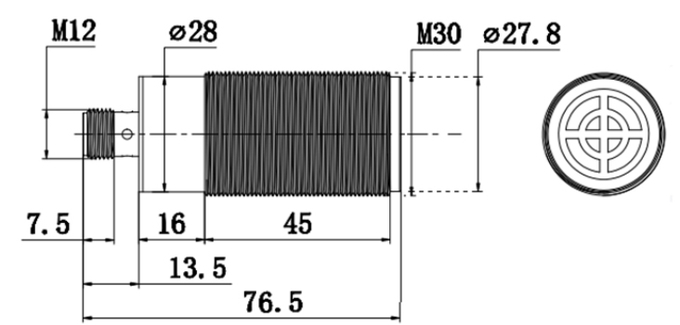

| Dimension | 30mm*76.5mm |

| Weight | 85g |

| Fixed type | use two nuts to clamp on the site,or fixed in place by twisting |

| Housing Material | Brass nickel plating |

| Color | Sliver |

| Interface | AT1042S:SMA AT1042T:TNC |

| Working Temperature | -40℃~+85℃ |

| Humidity | 5%~95%RH |

| Waterproof/dustproof | IP67 |

Application:

Power Battery Assembly

Install the reader at the RFID collection point, and the on-line station collection point reads the RFID tag in the material box to obtain the information of slots in the material box (each slot is equipped with a cell with different voltage), The voltage value/grade of the test cell is written into the material box RFID tag at the test station of the voltage cell. When the cell is classified, read the RFID tag information of the material box and connect the robot in real time to automaticaly put the cell into the corresponding cell transport track. After the robot takes down the cell with different gear from the transport track and puts them into the same material box it will write the cell gear information into the RFID tag of the material box. Through the operation of each station on the RFID tag, a series of processes such as cell division, transportation, encapsulation, and assembly are completed in the process of cell assembly.

RFID readers allow you to optimally manage machines, tools and materials, reduce production costs, shorten delivery times, reduce the number of errors and increase production efficiency. You can achieve up-to-date data, available wherever and whenever we need it, is the basis for effective decisions.

Industrial RFID readers collect data automatically , allowing you to track material flows,monitor the efficiency of machinery and equipment,monitor the condition of fixed assets.

Dimension Drawing(mm):

FAQ

1. What’s your Payment?

PayPal or T/T (Bank transfer) or Western Union and Ali trade Assurance are accepted.

2. What's your MOQ?

Big Order or Sample Order is accepted by our company.

We understanding new customers may take sample testing to know our quality and service.

3. What is the warranty?

3 years warranty for core device from the date of delivery,A lifetime technical support.

We will return full money to customer if we did not shipping right items as contract.

4. What’s your delivery time?

Around 2~10 working days according to exact order quantity and stock situation.

5. Why choose us?

With us make Win-Win Business Situation!!!

24 *7 hours after sales service

We accept "PayPal", credit card to convenient customer make payment.

Quality Assurance Contract

Full refund in case of bad quality

Online supports if any technique issue.

Both Small Order and Big Order are accepted.

Accept OEM/ODM order.