Sinotectronics Inc. |

|

21.3 Inch ITO Projected Capacitive Weida Chip Touch Screen with Glass Sensor

1. Product Description

MST G + G Capacitive Touch Panel is made of a surface tempered glass and a ensor glass with Pcap technology. Projected Capacitive Technology permits more accurate and flexible operation by etching the conductive layer on the touch screen. GG is suitable for mass production and has better appearance properties, but it has high investment costs and is heavier than film-based panels.

2. Basic Features

| Item | Feature | Remarks |

| Controller | WD8752 | - |

| Channel | TX: 40 RX: 50 | - |

| Power | 5V | USB: 4.7V ~ 6.0V, Typical:5V |

| Communication | USB | USB: 2.0 Full Speed |

| Number of Touch point | 10 | - |

| O.S. | Windows/ Android/ Linux | plug and play |

| Power Consumption | 1.Active Mode: Max.120mA @ USB Input 5V 2.Idle Mode: 90mA @ USB Input 5V 3.Sleep Mode: less than 1mA @ USB Input 5V | |

| Item | Specification | Unit |

| Viewing Area | 432(L)×324(W) | mm |

| Cover Lense O.D. | 491.3(L)×382.5(W) |

4. Optical Characteristics

| Item | Specification | |

| Transparency | Viewing Area | ≧85% |

| Item | Specification | Unit | ||

| Stacked structure | Cover | 2.0 | mm | |

| LOCA | 0.2 | mm | ||

| ITO | 0.7 |

mm

| ||

| Sensor Glass | ||||

| ITO | ||||

| Sensor Dimension | OD Size | X | 450 | mm |

| Y | 343.6 | mm | ||

6. Drawing

7. Details

8. Advantages of G+G Structure

(1)High transmittance,>85%.

(2)Hard and anti-wear surface.The hardness is 6H.

(3)Excellent corrosion resistance.

(4)Sensitive touch and stable performance.

9. Touch Panel FPC Test Items and Criteria

Test Item | Qty (pcs) | Touch Panel FPC Test Items and Criteria |

Direct PullingTest | 5 | Test Conditions: 1. Pulling weight: 500g. 2. Pulling speed: 25 mm/min 3. Pulling angle: 90o 4. After test, verify touch panel functionality via test jig Pass Criterion: - No damage of FPC itself - No any peeling on FPC located on bonding pad area - No functional failure after test |

Bending test

| 5 | Test Conditions: 1. 45 degree bending: 100 times 2. 90 degree bending: 200 times 3. After test, verify touch panel functionality via test jig Pass Criterion : - No damage of FPC itself - No any peeling on FPC located on bonding pad area - No functional failure after test |

| 5 | Test Conditions: 1. Flex bending: 30 cycles (Each cycle: 0o -> 180o --> 0o) 2. After test, verify touch panel functionality via test jig 3. bending ф=1 mm Pass Criterion : - No damage of FPC itself - No any peeling on FPC located on bonding pad area - No functional failure after test |

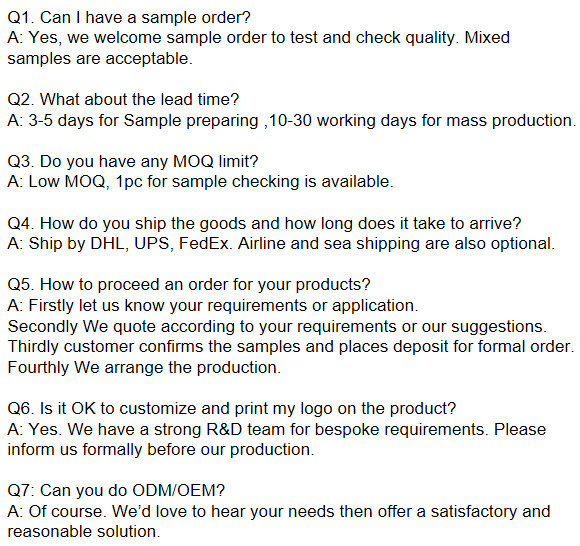

10. FAQ