Jinan Lijiang Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

Item. | Spec. |

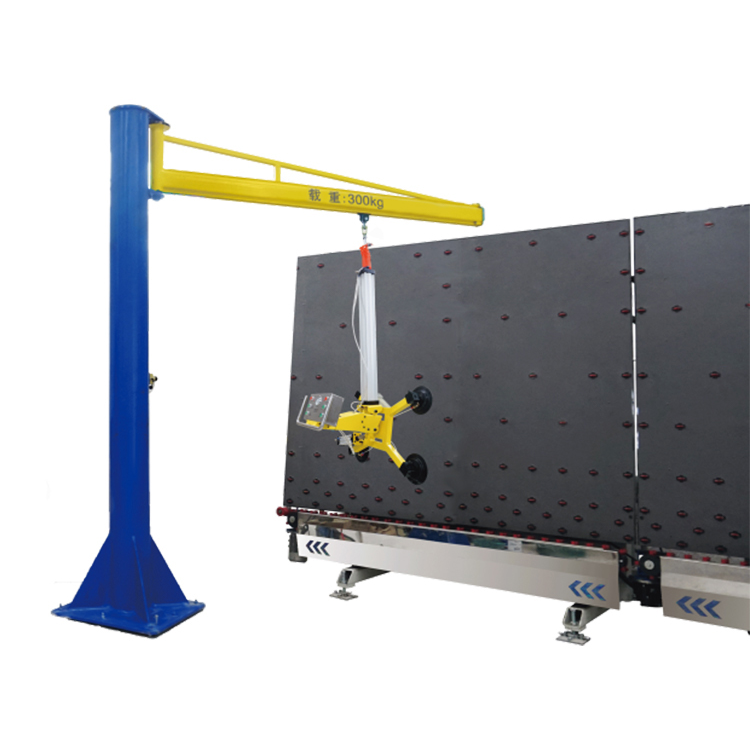

Safety-absorption | 200KG/400kg/600kg/800kg |

Performance | Rotation 0-270 degree and lifting 600-1200mm |

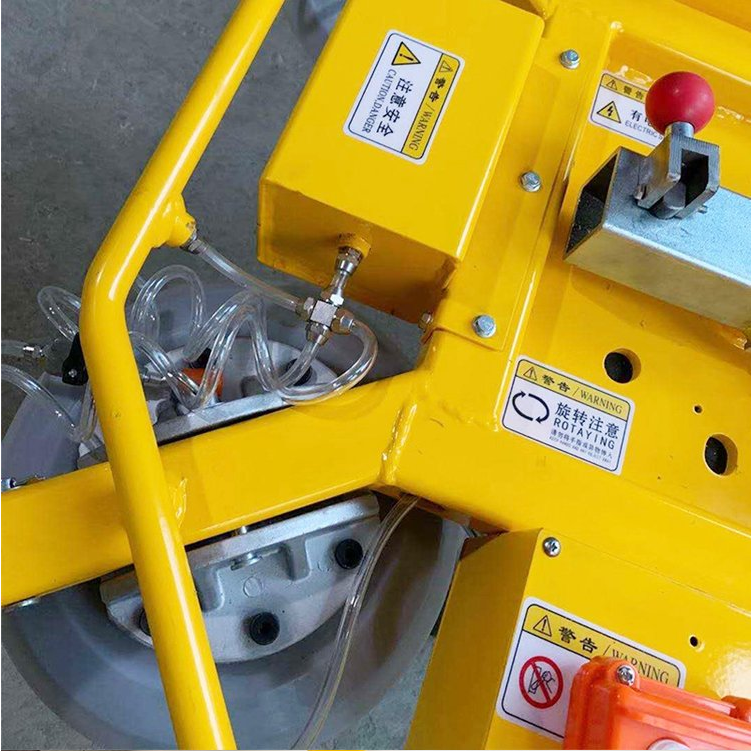

Quantity and size of sucker | 2/4/6/8/12 |

Working gas source | 5-8 Pa |

Voltage | DC12V (Built-in 2 batteries for long battery life) |

Battery life | It can be used for 3 to 5 days after charging once.(In addition, it

can also be connected to the power supply.) |

Single suction cup loading | The actual test weighs up to 150kg or more |

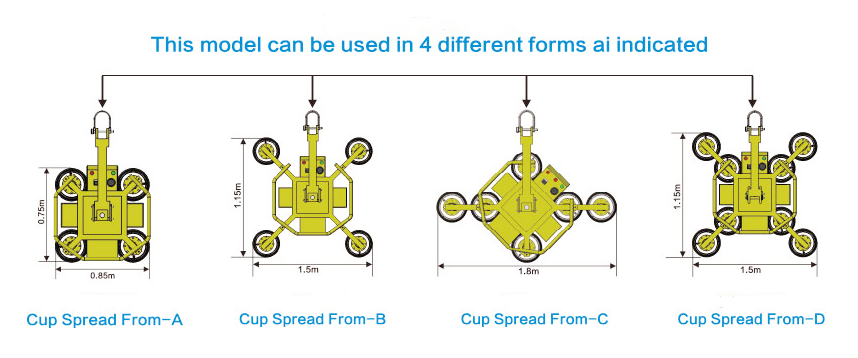

Length dimension | Control cabinet: 0.3m; Suckers: Optional 1-5m |

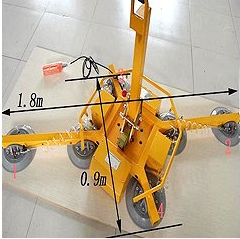

Width dimension | Suckers: Optional 1-1.5m |

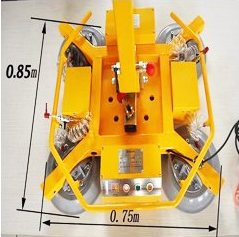

Outer size | L1120mm*W660mm*H620mm |