Jinan Lijiang Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

Full-Automatic Vertical Insulating Glass Sealing Line with max glass size 2500*4000mm

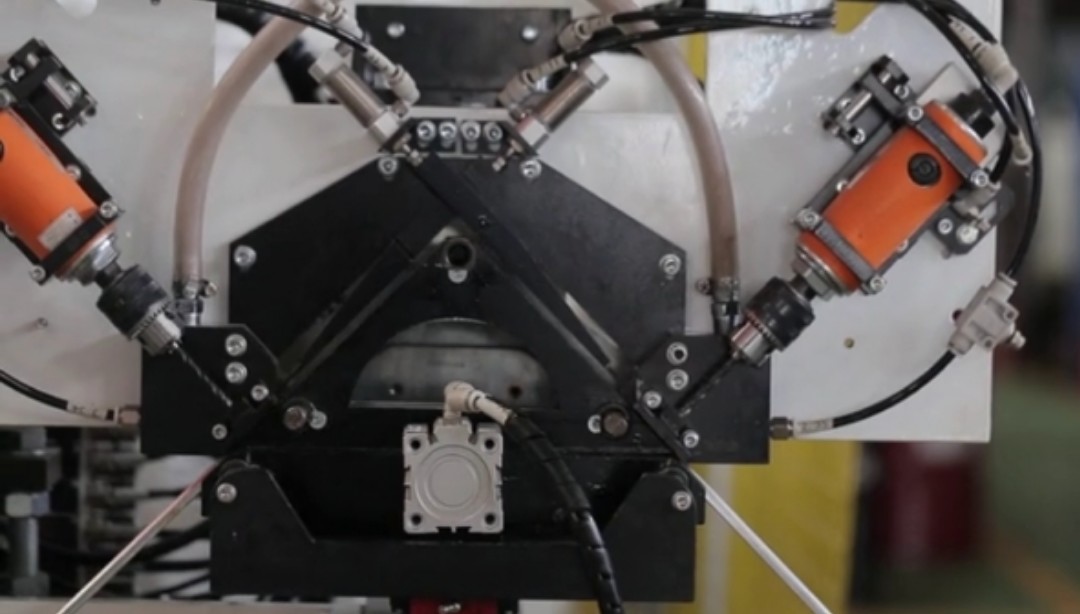

►Application of insulating glass sealing robot

l Min & Max glass sizes can be optional

l Adopt 8 servo motors

l Adopt Japan ANCHUAN servo control system with stable performance

l Automatically measure glass size, glue depth and glue speed with linear adjustment

l Adopt timing belt to keep smooth convey with accurate position

l Spares are produced with high standardization and high precision, ensure the machine can be used with long-term working

l The glass corners are full without air bubbles, smooth surface, no need to

l Full automatic and high-efficiency machine

l New scraper design, especially for making train IG with very even sides and corners, without any bubbles.

l Automatically repair glass corners with beautiful surface

l Smooth convey without scratch and pollution

l Single-function parts are equipped with manual functions, easy adjustment

l Shaped IG units (Optional)

l Stepped IG units with four sides (Optional)

l Double and Triple IG units

►

Ø Two Sets of Pump A & Pump B

Equipped with two sets of A components and two sets of B components, which can be used for two kinds of different sealants, such as silicone rubber, polysulfide rubber, silicone structural adhesive and so on.

Ø One Set of Pump A & Pump B

Equipped with single A component and single B component. Glue A and B automatic mixing, automatic ratio.

Ø Back Glue Device

When the pressure increasing, more Glue B will flow back automatically, saving materials.

Ø Dyad Body Device

The dyad body device has two functions. The left one is used for filtering impurities and moisture when filling gas into , then the right one plays the role of lubrication.

Main technical parameter

| Max.glass size | 2000*2500mm |

| Min.glass size | 300*300mm |

| Glass thickness | 12-56mm |

| Working speed | 5-40m/min |

| Air pressure | 0.5-0.7MPa |

| Squeeze pressure | 32MPa |

| Overall dimension | 8000*1500*2700mm |

Jinan Lijiang Automation Equipment Co., Ltd. is located in the beautiful spring city------Jinan. It is an enterprise which integrated glass processing equipment research and development, sales and service into a whole world . As it is close to Beijing-Shanghai high-speed rail, the transportation is very convenient.

The company is committed to building high-end insulating glass machinery and equipment by learning from famous experts, establishing the research and development centers, cooperating with domestic and foreign well-known enterprises, importing advanced technology and so on. Now, our friendly partners include North Glass, Xin Fuxing, Yaohua, Dalian Huaying, Beijing Guanhua, Shanghai Hao Jing, Sichuan Li Hehua and other well-known enterprises. Since the establishment of the company, our products have been exported to Europe, America, South America, the Middle East, Southeast Asia, India, nearly 30 countries and regions. At the same time, our company worked with the well-known domestic research institutes, such as the North China Industrial Group, Shandong University and others, to constantly improve the level of technical research. So far, we have independently produced the vertical automatic IG production line with filling gas on line, the vertical IG sealing robot, the automatic spacer bending machine, the automatic desiccant filling machine and the new fully automatic butyl extruder machine, its technology and quality have reached the highest leading level in China.

With the rapid development of insulating glass industry, LIJIANG is looking forward to working with you for win-win situation and jointly creating a new world.

Other products of LIJIANG GLASS

LJGZ2020 Desiccant Filling Machine

►APPLICATION

Desiccant Filling Machine can automatically achieve actions of drilling holes automatically in the spacer frames, filling desiccant and sealant. Desiccant Filling Machine control system adopts Germany Siemens, so the speed of filling is quick and stable operation ensure the valid closure property of sealant. Desiccant Filling Machine improves quality of insulating glass, it’s a necessary equipment in the process of insulating glasses.

1, Protection device for machine head.

►Technical data

| Filling aluminum frame’s maximum size | 2500mm*2500mm |

| Filling aluminum frame’s minimal size | 300mm*250mm |

| Article aluminum specifications | 5.5-24mm |

| Air source | ≥0.65MPa |

| Power supply and power consumption | AC220V 50Hz 1.8KW |

| Molecular sieve diameter needed | 0.5-0.9mm |

| Dimension | 1300mm*1100mm*3650mm |

| Name | Brand | Name | Brand |

| PLC | German SIEMENS | Triplet | TAIWAN AIRTAC |

| Low voltage electrical apparatus | German SIEMENS | Solenoid valve | TAIWAN AIRTAC |

| Sensor | Korea AUTONICS | Gas driller | Taiwan BOA |

| Guide | Taiwan TBI | Switch power | Taiwan TEND |

►Protection device for machine head.

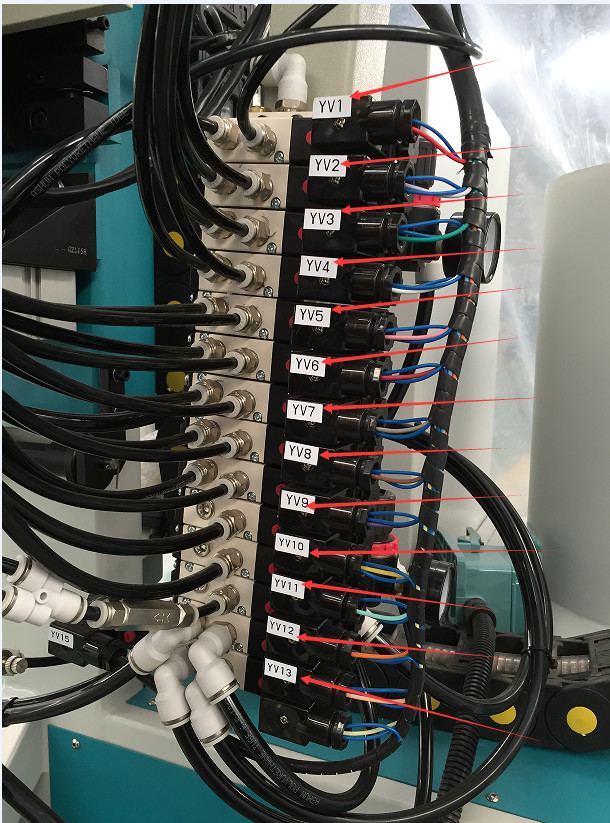

►All the electrical wires have the ID number,it can match with

specification , also it will be very easy for the further

communication in the after sales service .

►Electrical component are all Germany Brand-Siemens.

►All spare parts have ID Number for offering the convenience in after sales service.

Desiccant Filling Machine can automatically achieve actions of drilling holes automatically in the spacer frames, filling desiccant and sealant. Desiccant Filling Machine control system adopts Germany Siemens, so the speed of filling is quick and stable operation ensure the valid closure property of sealant. Desiccant Filling Machine improves quality of insulating glass, it’s a necessary equipment in the process of insulating glasses.

1.The desiccant filling machine height of can be adjusted according

to the size of spacer frame

2.Desiccant filling Filling time can be adjusted

3.Desiccant filling auto loading and replenish

4.Desiccant filling Auto drilling, filling and sealing function

5.Desiccant filling use Germany Siemens PLC control system

6.Desiccant filling touching screen interface, simple and visible

8.Desiccant filling adopt vacuum pump loading device ,increase the loading speed

9.Desiccant filling can use big bucket desiccant ,save desiccant refill time ,improve the work

efficiency