Jinan Lijiang Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

Product Description

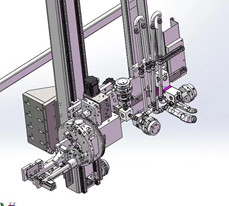

1. The Introduction of System

This system is controlled by motion controller, which can achieve

the continuity of sealing for various size of insulating glass. It

has two sets of independent sealant supplying system for double

glazing/triple glazing insulating glass. It can produce double

glazing and triple glazing, meanwhile it can seal the triple

glass's two space at one time. The common machine working way is

from right to left when facing the machine. The system is composed

of three sections: input section, sealing section, output section.

2. Features

1) Friendly man-machine interface is concise users will be more

convenient to operate.

Touch screen (the language can be designed as customer's demands)

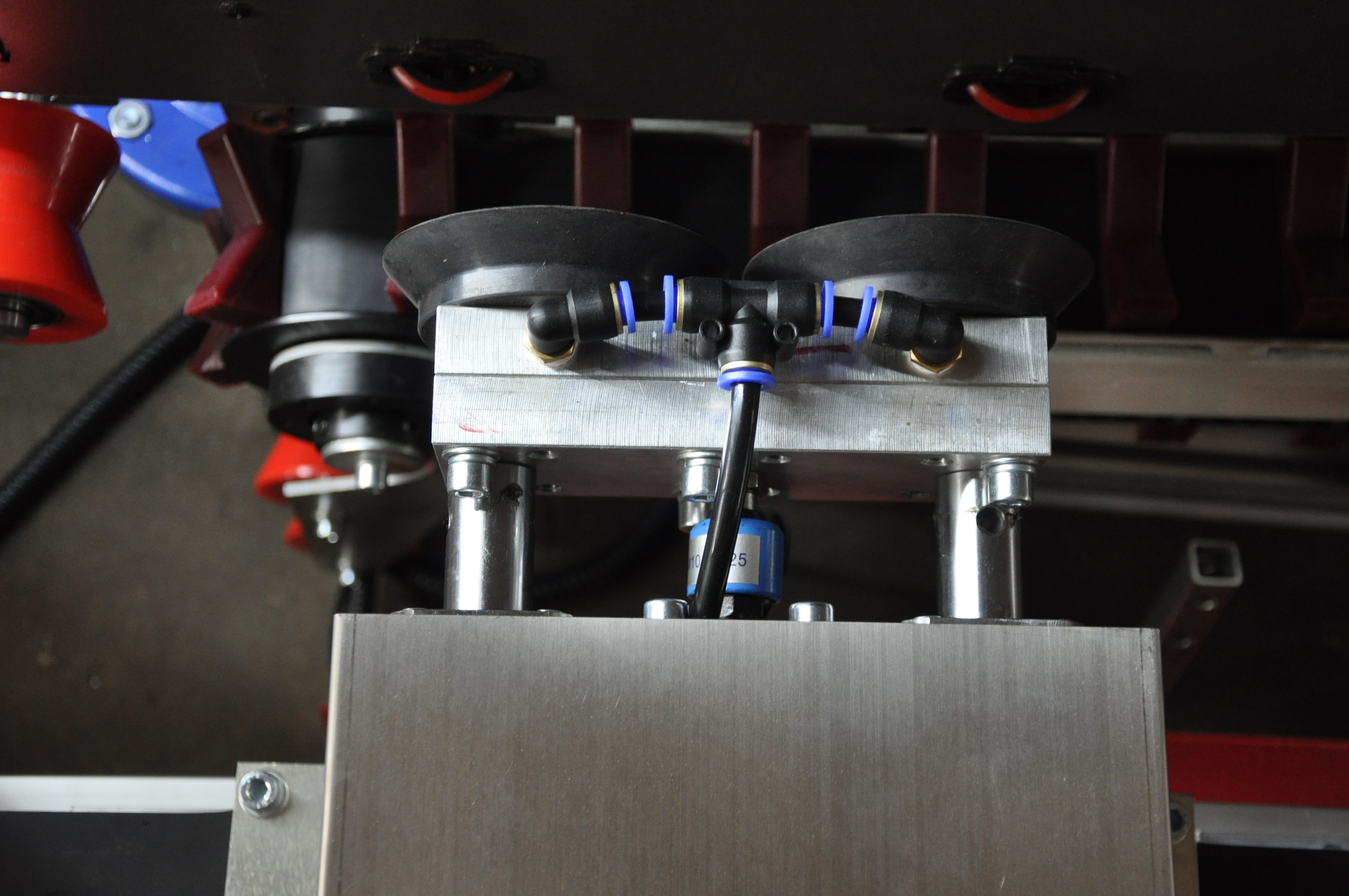

2) This system has the thickness detection device and depth detection device by the high resolution sensors. Combined with automatically sealing function and adjusting the volume of the glue, it can greatly improve the efficiency of production. The sealant supply system is from Taiwan AIRTAC.

3) The special mixer is equipped, and making the black sealant and white sealant mix well.

4) The system has two sets of sealing system (optional), to change

glue easily during production.

5) This system can be used in triple glazing glass. Firstly, it

glues for the first space, when it finishes, the rubber head will

adjust the angle for gluing the second space.

6) The V belt can adjust automatically according to the thickness

of glass. Accurate synchronous belt transmission system to ensure

the glass to move stably and clearly.

7). Rubber head pressure device can adjust glue head moving cylinder pressure through the precision of electric proportional valve to make the glue head attach the glass more smoothly. The structure of centering rubber head can adjust the rubber head according to the thickness of glass to ensure the effect of the gluing. The sealing of all edges and corners enriches no air bubbles, fully coating, without manual trimming.

8).The system has the "connection" system. The "connection" means

that it can combine the production line with the sealing system to

improve the production efficiency.

9).The cleaning function: When it is used for a long time or not

used, the worker must clean the rubber tube (blunt glue) to avoid

solidifying the rubber tube. When the worker adopts the cleaning

function, the glue in the rubber tube will be discharged to avoid

solidifying and protect rubber tube.

10). All components are high standard to be sure that the machine

can be used stable for a long time.

11).The edge of glass is full without airline, and the corner is

enriched without repairing it.

12) The third section stores the glass.

Technical parameter

Electrical Component

Installation:

If the buyer needs, the seller will send one or two technicians (one is electrical engineer, one is mechanical engineer) to install the machines and help train the workers. The buyer should be responsible for the round air tickets and be responsible for the hotel, meal fees. the buyer should pay the technician salary, which is 50USD per day per person.

Warranty time:

One year. From the date of signing Test Acceptance

During the warranty time, the broken spare parts caused by the

machine problems are free to be provided for the Buyer, and the

Buyer is responsible for postage. Provided that the spare parts are

broken caused by inappropriate operation or other irresistible

incidents, includes all kinds of natural disasters, fire, wars,

etc, the Buyer shall be responsible for all fees, including spare

parts fee and postage.

More Details Pictures