Jinan Lijiang Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

Overview of Butyl Sealant Coating Machine

As one of the important equipment of producing Hollow glass, the effect of butyl glue is directly related to the sealing of insulating glass. The equipment is automatic one, easy to operate and convenient to use.

Butyl Sealant Coating Machine is used for spreading spacer frames evenly with hot melt butyl. The operation of the butyl extruder is more easier than before,it uses large electrical control panel . The conveyor of aluminum is controlled by frequency converter. The speed can be adjusted from 0m/min to 47m/min. Automatic Butyl extruder machine LJTB01 is a special equipment for the production of making Hollow glass.

Features of Butyl Sealant Coating Machine

1.Extrusion coating machine main accessories are German brands. PLC program control, stable performance

2. It is convenient to adjust the height of the crossbeam and solve the problem of exposed white effectively and conveniently

3. Unique design structure, with automatic exhaust function, to ensure continuous glue application

4. Non adhesive synchronous belt is used, and talcum powder is not needed for cleaning

5. It is convenient and practical to use movable vertical and horizontal sealant

6. Glue application speed can reach 47m / min

7. Automatically adjust the width of glue head, and the integrated control of quick opening valve ensures the consistency of double-sided gluing

8. It can save the glue consumption compared with the ordinary butyl rubber machine, and the gluing can reach 7g / m

9. Touch screen operation, simple and practical

10. Butyl extruder machien is convenient for operation,the rubber cylinder adopts pull-up structure.

11. Automatically adjust the glue output according to the speed change

12. The hydraulic system imported from Germany is adopted to ensure even and full glue delivery

Optional functions:

200L glue cylinder is optional

Details of Butyl sealing machine

1.Simple operation,KINCO Touch Screen

Clear interface, Smart touch screen,Updated programming.

2.stable performance,Adopt Siemens brand, Germany Siemens parts

3.Alarm system

Automatically alarm system, reminding adding butyl.

4.Germany HAVE Valve,more stable performance.

Adopt Germany’s Harvey valve

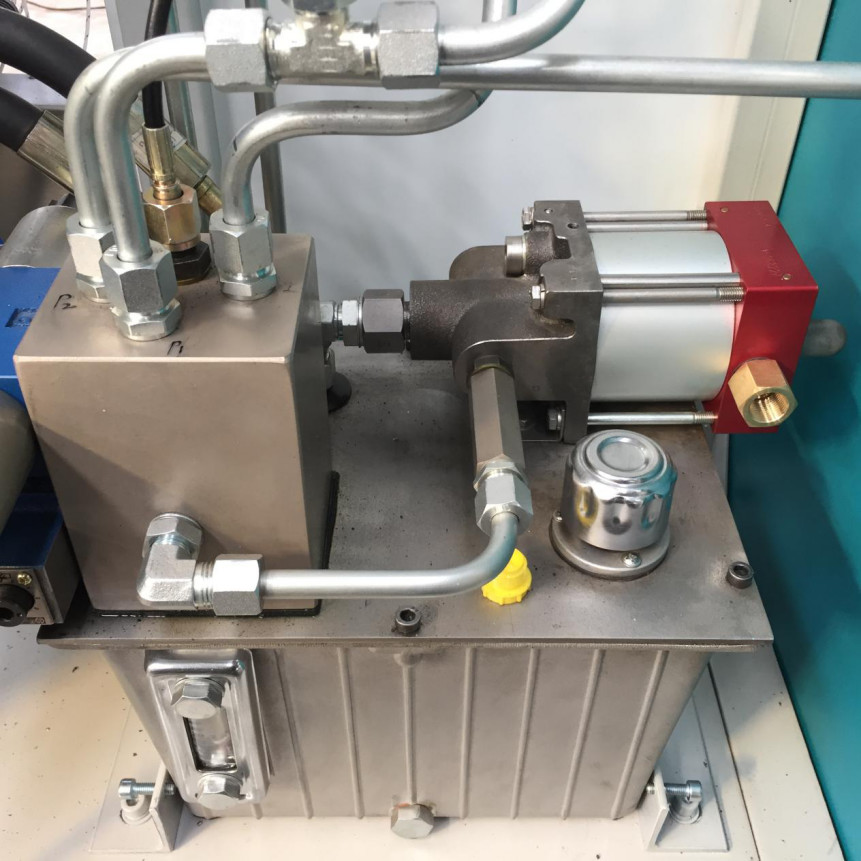

5.Germany Maximator Cylinder

The supercharging system adopts famous pneumatic and hydraulic cylinder, control the pressure of outlet oil strongly.

7.Detail picture of butyl spreading machine

Tech parameters of Butyl Coating machine

| Squeeze pressure | 10-18MPa |

| Temperature | 110~140℃ |

| Glue thickness | 0.3-0.5mm |

| Glue width | 3.5mm |

| Aluminum spacer width | 6A - 27A |

| Speed | 5-47m/min |

| Diameter of butyl cylinder | 200mm |

| Air supply | 0.4m³/min |

| Air pressure | ≥0.6MPa |

| Total power | 380V, 5.7KW,50HZ |

| Dimension | 2800×700×900mm(L×W×H) |

| weight | 650kg |

Related Product

Sealant-spreading Machine LJST02A

Main feature of sealant spreading machine

• High pressure protect device

• Imported motor system to improve equipment efficiency

• Imported sealant gun,stainless steel mixer

• Anti-back flow control structure

• Mixed rate detector can control the rate of two kinds of glue

Technical data of Two pump sealant spreading machine

| Working air pressure | 0.3-0.6MPa |

| Sealant spreading pressure | 15-20MPa |

| Sealant volume | 4L/min |

| Diameter of A/B sealant | 570mm/280mm |

| Sealant spreading air pressure ratio | 50:1 |

| Mixed rate | 6:1-14:1 |

| Air supply | Flow 0.8m3/min |

| Air pressure | ≥0.8MPa |

| Overall dimension | 1100*950*1630mm |