Jinan Lijiang Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

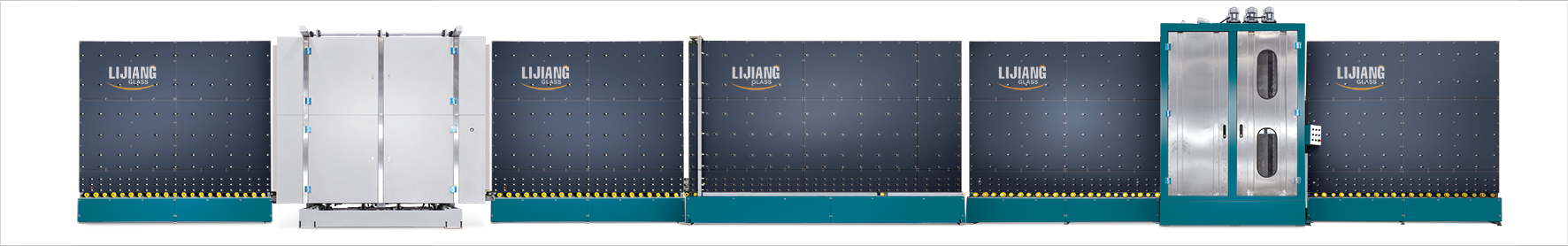

Vertical Insulating Glass Production Line with gas

* There are seven parts in the Vertical Insulating Glass Production Line , include Washing section,Checking glass and installing frame section, Four Transfer sections,Pressing & Gas filling machine.

* Washing machine - 02

* Checking glass and installing frame section - 04

* Transfer sections - 01/ 03/ 05/ 07

* Pressing & Gas filling machine - 06

1,Glass washing machine

Glass washing machine have Linkage setting, Glass washing machine can automatically recognize the glass thickness, the air knife moves forward and backward to adjust the distance so that the relative distance between the air knife and the glass is constant.

*Glass washing machine have 6 pieces of soft brushes, 0.1mm

*Glass washing machine adopt Europe's advanced anti-noise system,

below 90 decibels

* Glass washing machine haveWater filter device

* Glass washing machine have Water heating system

* Glass washing machineUsing 304 stainless steel materials

2,Check glass & install frame section

In this part ,the machine Using LED lights to check the glass if it is washed clearly, if there is any stains and water stains, the sensor will alarm.

It is used to help workers install spacer frame on glass.

3,Pressing & filling argon gas

The Pressing part in the Vertical Insulating Glass Production

Line have Special adjustable points to keep the back plate straight

all the time. It can guarantee that the pressing board will remain

straight all the time after used 10 or 20 years.

| Max.glass size | 2500mm*3500mm |

| Min.glass size | 280mm*400mm |

| Glass thickness | 3-15mm / 19mm |

| Insulating glass thickness | 50mm / 60mm |

| Glass washing speed | 2-10m/min |

| Glass conveyor speed | 45m/min |

| Washing brushes | 3 pairs |

| Water supply | Water consumption:0.5t/h conductivity:40μs/cm |

| Air supply | Flow: 0.8m/min |

| Air pressure | ≥0.8MPa |

| Total power | 3P 380V 50HZ 40KW |

| Dimension | 23500*3500*3700mm |

| Weight | 6500kg |