Jinan Lijiang Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

250*200mm Warm Edge Spacer Bender Use For Insulating Glass Production Spacer Bending Machine

The automatic spacer bending machine is a special equipment for the production of aluminum insulating glass frames, which replaces the traditional manufacturing technology. This equipment can manufacture a variety of polygonal convex aluminum frames with one aluminum strip at a time, thus enhancing the strength of the aluminum frame, thus improving the sealing effect of the insulating glass.

Equipment details

Siemens PLC control system adopted

There are 4 Siemens servos

We adopt 4 sets of racks that can store spacers of different sizes.

Use Siemens servos to replace different racks.

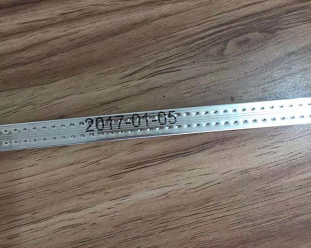

Aluminum spacers are automatically cut and sent

Continuously curved spacer frame

Automatically avoid connection corners when folding or cutting

Instead of grabbing the spacer from the bottom, the machine grips

the spacer from the top, solving the old-fashioned flipping

problem.

Uses industrial computer technology that allows industrial computer

workers to draw on the spot and directly fold drawn graphics.

A dedicated mechanical hand device is used to fold the large

spacing frame

Technical data

| Max.bending size | 2000mm*2000mm (2500mm*2500mm) |

| Min.bending size | 250mm*200mm |

| Aluminum spacer width | 5.5-27mm |

| Dimensional error | ±0.5mm |

| Angle error | ±1º |

| Processing speed | ≤26s |

| Air supply | ≥0.65MPa |

| Total power | AC220/380V 50Hz 2.5KW |

| Dimension | 10500mm*2200mm*2600mm |

Leading Technology

Company Information

Founded in 2009, Kation-Tech specializes in R&D, production and sales of insulating glass machinery and related auxiliary equipment for glass deep processing industry and door and window construction industry. The basis of professional processing of insulating glass machinery, aluminum-plastic door and window machinery and related auxiliary materials, etc. Until 2019, we had been exporting glass machinery and materials to America, South America, Europe, Middle East, India, etc. , in nearly 30 countries and regions. We have established a perfect international business relationship with 10 strong agents and strive together to build a world famous international brand. Kation-Tech, with knowledge, profession and honesty, win the future together!

Electrical parameters

| NAME | BRAND | NAME | BRAND |

| PLC | GERMAN SIEMENS | Triplet | Taiwan AIRTAC |

| Low voltage electrical apparatus | GERMAN SIEMENS | Cylinder | Taiwan AIRTAC |

| Servo motor | GERMAN SIEMENS | Solenoid valve | Taiwan AIRTAC |

| Servo driver | GERMAN SIEMENS | Switch power | Taiwan TEND |

| Relay | JAPAN OMRON | TOUCH SCREEN | Taiwan WEINVIEW |

| Sensor | KOREA AUTONICS | GUIDE | Taiwan TBI |