JinJiang LiQi Mould Co., Ltd |

|

Customized Plastic Electronic Housing Flanged Plastic Case ABS Box

Product features:

1:Accessories are packaged in small bags

2:The hole can be machined as required

3:Complete insulation protection

4:The color and material can be customized in batch

5:Equipped with corresponding screws

Main usage:

Hand-held enclosures have differnt names because of regional

differences and uasge difference.For the industry,control box,

instrument case,electronic products shell are mainly used.The

portable instrument box is mainly used in the following indoor and

outdoor fields:electrical, communications, fire control facilities,

steel smelting, electronics, electric power, railway, construction

sites, mines, airports, hotels, large factories, environmental

hazards facilities, etc.

Advanced plastic enclosures for housing all types of electronics

equipment:

The Plastic Electronic Housing covers many different applications,

for example handheld Plastic Electronic Housing, wall mount

housing, flush mounting / DIN rail housing, desktop housing, table

top housing s, instrument housing, standard mounting rail housing

etc. Choose the Plastic Electronic Housing whose design, size and

configuration best meets your particular requirements. Modern

electronics packaging is characterized by ergonomic design,

user-oriented functionality and high-quality molding and finishes.

With all conceivable technologies available in-house, we can finish

and process the Plastic Electronic Housing and adapt them to your

requirements.

Products Description:

| Product Key word | Plastic Electronic Housing |

| Operating Temperature | -20C to 90C |

| Protection level | IP65 of IEC 529 ; The lid and base incorporate a tongue and groove

sealing system with a silicon gasket ;better anti-corrosion performance. |

| Sample | Free available sample in hands; pay the mould fee to get a exact customzied sample |

| Application | widely applied for Control module and mounts on din rail |

Features:

Made from high quality Plastic Electronic Housing flame retardant

material, with good performance, no corrosion, anti-static,

insulation resistance.

This box is resistant against dust and water, the protection grade

is IP65.

Strongly flame retardant and good insulation, anti-corrosive,

anti-static.

Good sealing performance, long service time.

Completely non-toxic, does not produce harmful substances.

Mainly used for indoor and outdoor electrical, communications, fire

fighting equipment, iron and steel smelting, petrochemical,

electronics, electricity, railways, construction sites, mines,

mining, airports, hotels, ships, large factories, coastal factories

unloading dock equipment, sewage and waste treatment facilities,

environmental hazards facilities, etc.

Junction Box with Accessories only, other accessories demo in the

picture is not included.

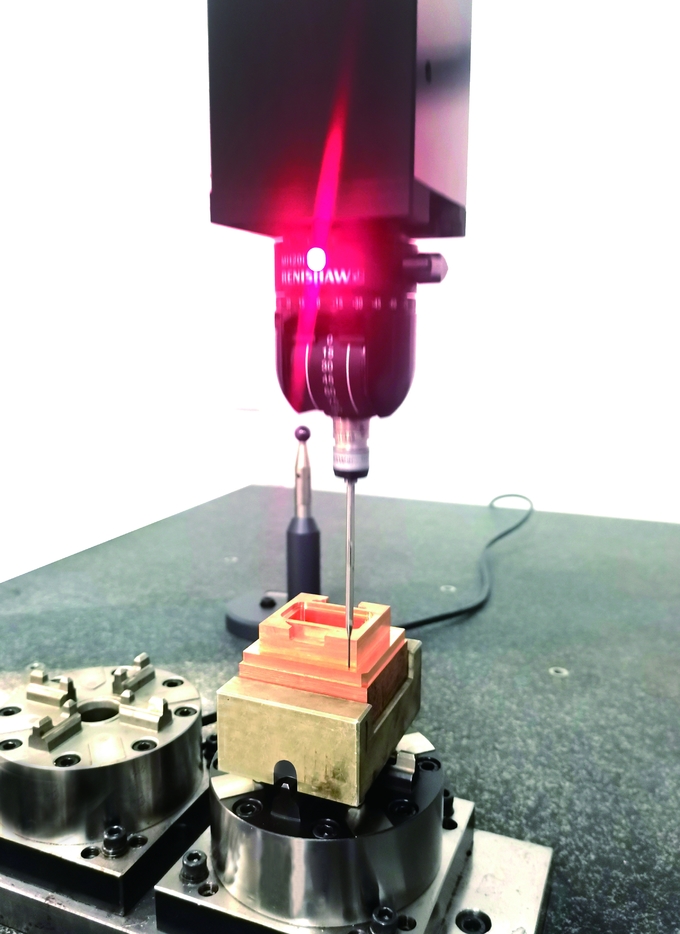

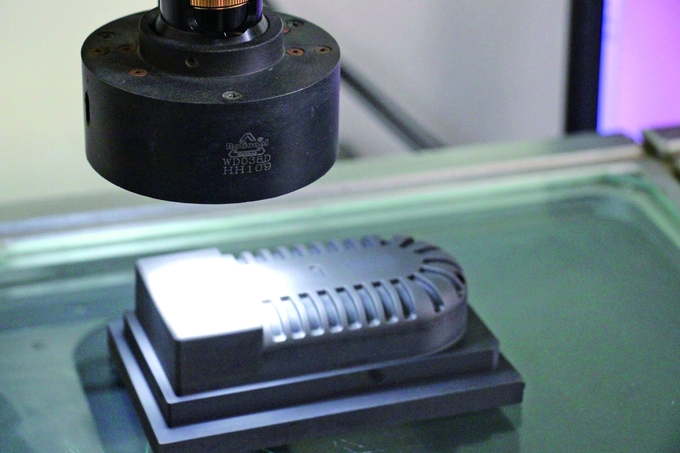

We can offer the full range of service from mold designing, making, plastic part molding to printing, assembly, package, and shipping arrangement.

1. In the service of plastic injection, Ideal plastic is more than just an injection molder.

2. We provide solutions to manufacturing from start to finish.

3. Our expertise enables us to provide clients with superior product by providing the

4. Highest quality in design, development, and solutions for precision injection molding and related manufacturing.

5. We have over 15 years’ production experience.

1. Professional experienced manufacturer for many years

2. Competitive price from factory

3. Timely and short lead time

4. OEM & ODM are welcome

FAQ:

1. When can I get the price?

A: We usually quote within 24 hours after we get your inquiry.

2. How long is the lead time for mold?

A: It depends on the mold’s size and complexity. Normally, it nees

about 25-35 days.

3. I don't have 3D drawing, how should I start the new project?

A: You can provide us a sample, we will make 3D drawing design.

4. Can we mass produce in your local?

A: Yes, you can leave the mould in our factory, we can produce for

you.

5. Can we get a sample when mould finished?

A: Yes, we usually send out samples for customers' checking, then

mass production after samples comfirmed.

6. Before shipment, how to make sure the products quality?

1) We have QC to inspect the products before each shipment.

2) We can send you videos to show the production process.

3) You can come to visit our factory or ask a third party for

inspection.

7. How could I pay?

A: Paypal, Western Union, T/T are acceptable, so just let us know

which is convenient for you.

8. How to ship?

A: By sea/ By air/ By Express.