JinJiang LiQi Mould Co., Ltd |

|

Plastic Middle 3D Printing Prototypes Reduced Saved Material Parts

| Products Name: | Plastic Middle 3D Printing Prototypes Reduced Saved Material Parts |

| Total Building: | 9800 Square Meters |

| Experience | 22 Years |

| Equipments: | CNC turning, Auto-Lathes, CNC Machining Center, Stamping Machines, CNC spring machining, cnc cuting machine, welding machine, Hydraulic press, stone polishing machine, auto-milling machine, Driling Machines, Heading Machines, Slotting Machines,Tapping Machines, Chamfering Machines, Grinder Machines,Polishing Machine and so on |

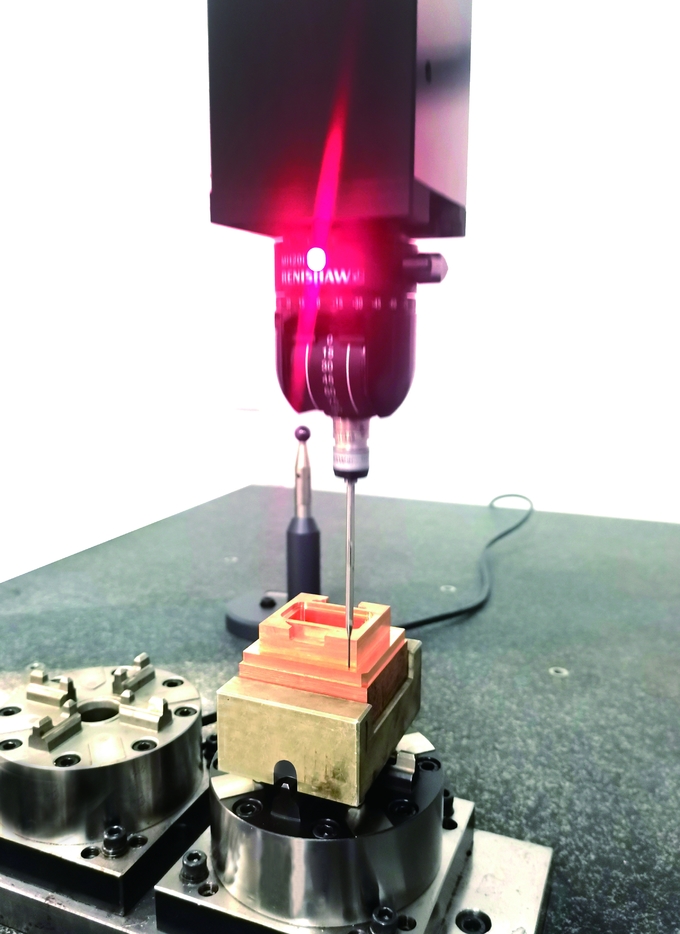

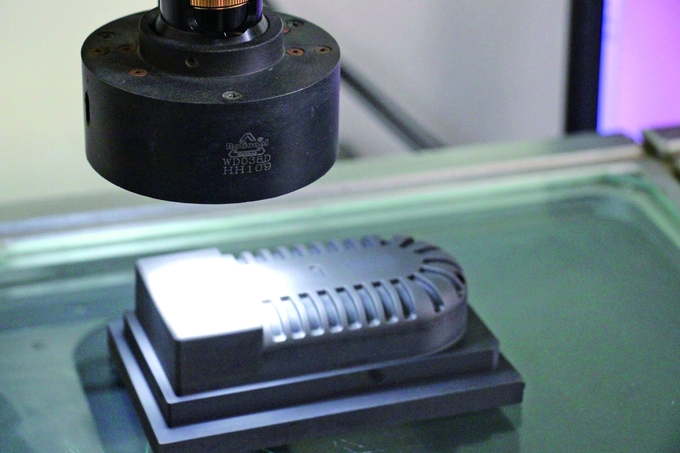

| Testing Equipments: | 3D measuring machine, Height Gage, Coordinate Measuring Machine, Hardness Tester, Video Measuring Machine, Roughness Tester, Torsion Tester, Salt Spray Tester,Slide caliper, Micrometer. |

| Material: | Titanium alloy, Brass, Bronze, Copper, Aluminum, Mild Steel, Stainless Steel, A366, Alloy, Carbon steel, ABS, PC, PEEK, PPS, PPS GF40, PPS GF30, POM, PET and so on. |

| Surface Treatment: | Zinc Plating, Nickel Plating,Chrome Plating,Passivation,Hardening, High Frequency, Black Anodizing,Black Oxide Coating,Degreasing,Brushing, Electronic polishing, Powder coating, Gold plating,Etc |

| Certification: | ISO, Rohs, Etc |

3D printing is quickly changing the manufacturing industry all over the globe. Not only is it more affordable than ever to create prototypes, but there is also a greater level of flexibility we haven’t seen before. This model of building products is starting to gain more attention, and it’s expected to be the new normal in the near future.

How exactly is 3D printing used to create prototypes? This guide will discuss 5 ways this method differs from the manufacturing of the past, and how these are changes for good. As product design and development moves towards 3D printing, we can expect to see these transformations and improvements.

1. Better Design

In the past, prototypes were used as a way to test designs. While that’s still true, there is significantly more room for flexibility at this stage than ever before thanks to 3D printing. The traditional manufacturing process required distinct stages. These stages all relied on digital models, and these came with limitations.

First, the prototype wasn’t able to be made with similar models or capabilities of the final product. This meant there were fewer opportunities for accurate design and testing. Now, the digital thread can be used throughout the entire process, and more accurate, well-designed models are available thanks to 3D printing.

2. Manufacturing as a Service

While we’ve recently come to know the term SaaS (software as a service), it looks like we need to say hello to another term MaaS. Manufacturing as a service is something that bloomed thanks to 3D printing. We are seeing companies with infrastructure built to support multiple design and production efforts for several clients, all while using the same 3D printing technology.

Companies with rapid tooling services are becoming the new normal. There are a lot of resources online that can help you understand better the process and find out more about it. Manufacturers will have quicker upgrades and a greater ability to produce quality work without changing their business model. MaaS is just another way 3D printing has made manufacturing more accessible.

3. Less Waste

Everyone today is concerned about their carbon footprint and reducing their impact on the environment, especially manufacturing companies. Governments across the globe have begun to implement stricter laws about waste and materials. Luckily, changes in efficiency have led to leaner initiatives that reduce overall waste and create more usable resources.

Our Services:

1. Professional experienced manufacturer for many years

2. Competitive price from factory

3. Timely and short lead time

4. OEM & ODM are welcome

FAQ:

1. When can I get the price?

A: We usually quote within 24 hours after we get your inquiry.

2. How long is the lead time for mold?

A: It depends on the mold’s size and complexity. Normally, it nees

about 25-35 days.

3. I don't have 3D drawing, how should I start the new project?

A: You can provide us a sample, we will make 3D drawing design.

4. Can we mass produce in your local?

A: Yes, you can leave the mould in our factory, we can produce for

you.

5. Can we get a sample when mould finished?

A: Yes, we usually send out samples for customers' checking, then

mass production after samples comfirmed.

6. Before shipment, how to make sure the products quality?

1) We have QC to inspect the products before each shipment.

2) We can send you videos to show the production process.

3) You can come to visit our factory or ask a third party for

inspection.

7. How could I pay?

A: Paypal, Western Union, T/T are acceptable, so just let us know

which is convenient for you.

8. How to ship?

A: By sea/ By air/ By Express.