SHENZHEN JC RAPID MFG FACTORY |

|

PRODUCT DESCRIPTION![]()

| Product Type | CNC turning, milling, drilling, grinding, wire EDM cutting etc. |

| Our Services | CNC Machining,Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion,Mould Making,etc |

| Material | Aluminum,Brass,Stainless Steel,Copper,Plastic,Wood,Silicone,Rubber,Or as per the customers' requirements |

| Dimension | As customers' request |

| Service Project | To provide production design, production and technical service, mould development and processing, etc |

| Drawing Format: | PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE |

| Testing Machine | Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

| Industry used | Machinery; heavy duty equipment; electronic device; Auto spare parts; optical telecommunication |

| Packing | Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes As customer's specific requirements |

| Trial sample time | 7-10 days after confirmation |

| Delivery time | 7-30 days after receive the pre-payments |

| Payment Terms | T/T,Western Union,Paypal |

| Precision of piece: | +/-0.01mm | ||

| Roughness of piece: | Ra≤0.1 | ||

| Quality standard: | DIN, ASTM, GOST, GB, JIS, ANSI, BS; | ||

| Products certification: | ISO9001:2008&2015, CE, RoHS, SGS; | ||

| Dimension: | Dia.500mm or 850mm width | ||

| Surface treatment: | Steel parts | Stainless steel parts | Aluminum parts |

| Galvanization | Polishing | anodized | |

| Black oxidation | Passivation | Sandblast anodized | |

| Nickel plating | Laser engraving | Colorful anodized | |

| Chrome plating | Sand blast | Brushed | |

| Heat treatment | Polishing | ||

| Powder coated | Chrome plating | ||

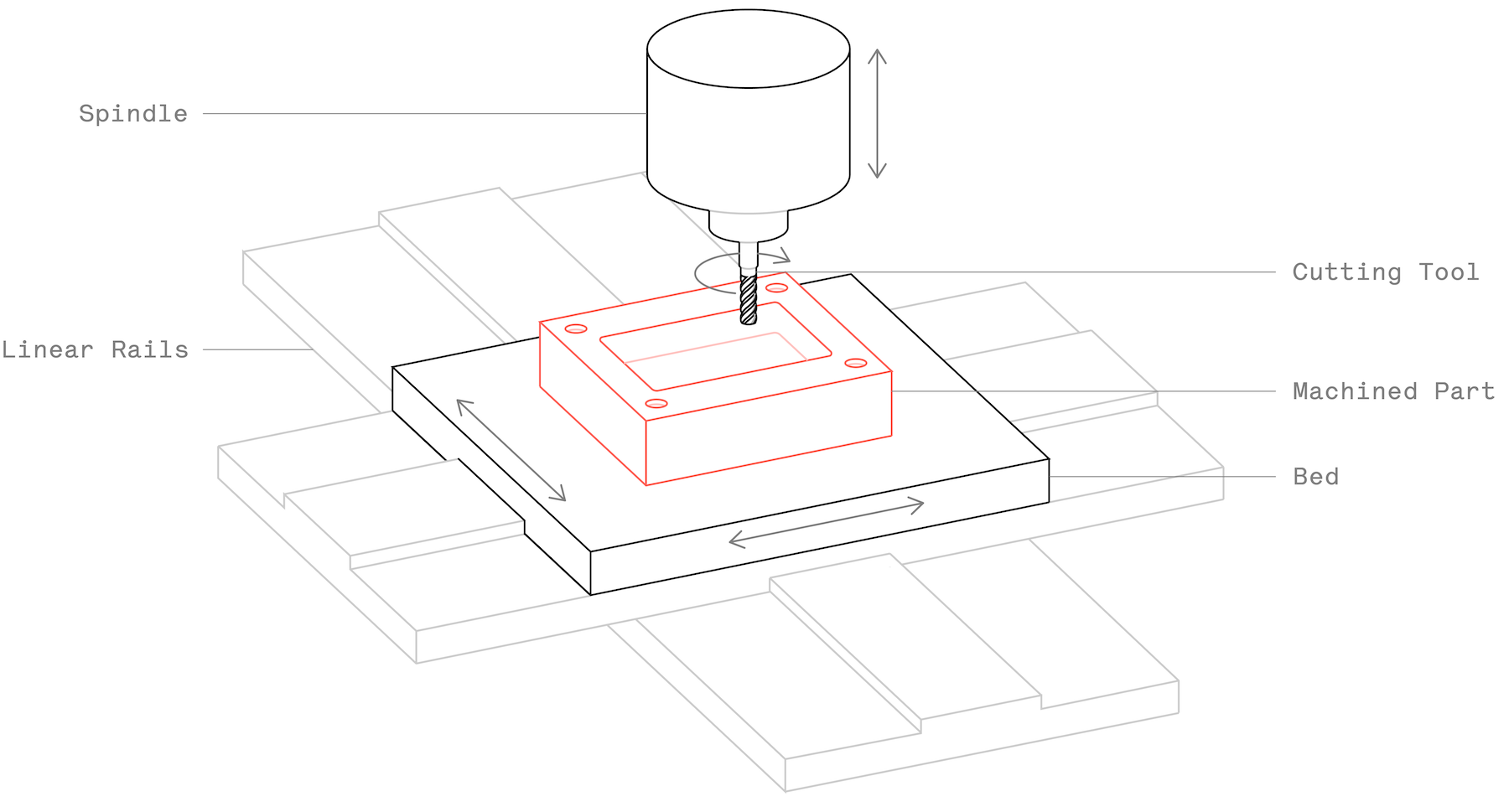

Milling is a cutting process that uses a milling cutter to remove the surface of the material by advancing in a direction at an angle. CNC milling machines are controlled in one of two ways: by computer or via manual override. Computer programming allows the machine to make the precise cuts required but the manual override allows a CNC machine operator to slow down or speed up or tweak the process if necessary.

What are The Advantages of CNC Milling?

CNC milling is more advanced than manual milling, and as expected, It offers a variety of benefits for both the machining business and the clients that outsource the production of their components.

![]()

![]()

![]()

Packing Details : Inner plastic bag,outside carton box,last is the

pallet,all are based on the customers' requirments

Delivery Details : 10-30 days after you confirm the samples

Payment terms: Payment<=1000USD, 100% in advance.

Payment>=1000USD, 30% T/T in advance ,balance before

shippment.If you have another question, pls feel free to contact

us.

A: You can send inquiry of our products,it will be replied within 1 hours.

A: If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material ,tolerance,surface treatments and the amount you need,ect .

This has never been occured right now ,as we treat the quality as our key of development.Quality and service is everything for us.