WUHAN GLOBAL SENSOR TECHNOLOGY CO., LTD. |

|

Verified Suppliers

|

|

LWIR Thermal Imaging Module With 640x512 12μM Infrared Detectors For Outdoors

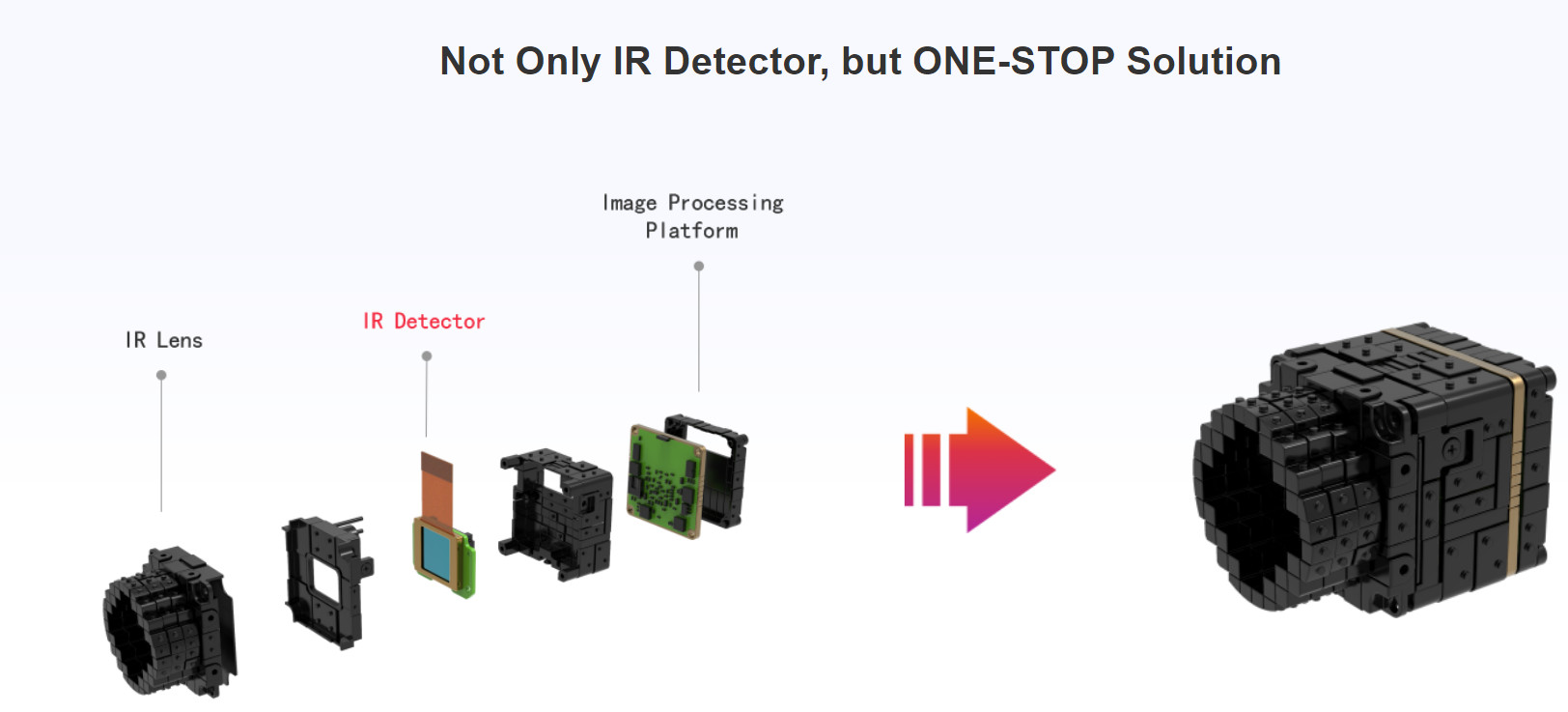

TWIN612 thermal module is a new arrival product developed by Global Sensor Technology. It integrates 640×512/12µm ceramic package uncooled infrared detector. With typical NETD<40mk, the TWIN612 thermal module could present clearer, sharper and more detailed image.

With temperature measurement range of -20℃~150℃/0~550℃, accuracy of ±2℃ or ±2% and frame rate up to 30Hz, the thermal module guarantees smooth thermal image and accurate temperature measurement.

The TWIN612 thermal module has the advantages of compact design, light weight structure and power consumption as low as 0.8w. With enhanced image algorithms and temperature measurement function, the TWIN612 thermal module presents more stable images and accurate temperature.

Ceramic packaging process is similar to metal packaging, which is a mature infrared detector packaging technology. Compared with metal packaging, the volume and weight of the packaged detector will be greatly reduced. Thus, the TWIN612 thermal module could be applied to industries that have strict requirements on size, weight and power consumption.

- Mini Size: 25.4mm×25.4mm×35mm

- Light Weight: 25g

- Typical NETD<40mk

- Sharp, Clear Thermal Imaging

- Typical Power Consumption as Low as 0.8W

| Model | TWIN612/R |

| IR Detector Performance | |

| Resolution | 640×512 |

| Pixel Size | 12μm |

| Spectral Range | 8~14μm |

| Typical NETD | <40mK |

| Image Processing | |

| Frame Rate | 25Hz/30Hz |

| Start-up Time | 6s |

| Analog Video | PAL/NTSC |

| Digital Video | YUV/BT.656/LVDS/USB2.0 |

| Image Display | 11 in Total (White Hot/Lava/Ironbow/Aqua/Hot Iron/Medical/Arctic/Rainbow1/Rainbow2/Red Hot/Black Hot) |

| Image Algorithm | NUC/3D/2D/DRC/EE |

| Electrical Specifications | |

| Standard External Interface | 50pin_HRS |

| Communication Interface | RS232/USB2.0 |

| Supply Voltage | 4~5.5V |

| Typical Power Consumption | 0.8W |

| Temperature Measurement | |

| Operating Temperature Range | -10℃~50℃ |

| Temperature Measurement Range | -20℃~150℃, 0℃~550℃ |

| Temperature Measurement Accuracy | Greater of ±2℃ or ±2% |

| SDK | Windows/Linux; Achieve Video Stream Analysis and Conversion from Gray to Temperature |

| Physical Characteristics | |

| Dimension (mm) | 25.4×25.4×35 (Without Lens) |

| Weight | 25g (Without Lens) |

| Environmental Adaptability | |

| Operating Temperature | -40℃~+70℃ |

| Storage Temperature | -45℃~+85℃ |

| Humidity | 5%~95%, non-condensing |

| Vibration | 5.35grms, 3 Axis |

| Shock | Half Sine Wave, 40g/11ms, 3 Axis, 6 Direction |

| Optics | |

| Optional Lens | Fixed Athermal: 13mm |

The TWIN612/R thermal imaging module is applied to the field

of Thermography, Security Monitoring, UAV Payloads, Robots,

Intelligent Hardware, ADAS, Firefighting & Rescue

1. Working Principle of Optical Gas Imaging

Optical gas imaging is a kind of infrared technology that could see

invisible industrial gases.

All objects in nature whose temperature is higher than absolute zero (-273.15°C) can emit infrared radiation. The intensity of infrared radiation depends on the target temperature. The infrared thermal camera converts invisible infrared radiation into visible infrared images according to the temperature difference or radiation difference between the target and the background or between various parts of the target.

After absorbing infrared radiation at specific wavelengths, infrared radiation difference will cause between the gas and the background.

The gas leak detection infrared detector with built-in narrowband filter only receives the infrared band near the gas infrared absorption peak, and can convert the gas into visible infrared images through the radiation difference between the gas and the background.

The optical gas imaging camera can quickly detect the gas without temporarily stopping the production line by identifying the infrared radiation difference between the gas and the background and visualizing the gas whether the leakage exists, and accurately locate the leakage source.