Hangzhou Joful Industry Co., Ltd |

|

Verified Suppliers

|

|

Double Shaft Industrial Waste Shredder For Textile Scrap , Waste Clothes Crusher , Waste Jeans Shredder

Introduce of double Shaft Industrial Waste Shredder For Textile Scrap , Waste Clothes Crusher

The double Shaft Industrial Waste Shredder For Textile Scrap is designed large torque shear equipment in order to break large & thick materials.The equipment is widely used to tear up the bundles of material.So no matter is loose or baled type the machine both ok to shred them.

With more than 15 years design and manufacturing experience on blade & cutters makes our shredder machines with more reliable quality and intelligent,clients have no irregular maintenance trouble during using.Thanks to our advantage on design,we also can support clients re-build the shredder if they have new crushing demand that the old machine design can not meet.Work with us will make every penny you spend safe and in their best value !

Features

Removable chassis

The simple box maintenance design provides a safer working

environment for maintenance personnel.Chassis overall processing,To

ensure that the spindle, bearing the installation of the

concentric, Extend the bearing, reducer life,So that the machine

running more smoothly.

Reducer

Equipped with ribbed high rigid cast iron box.Gear surface and gears are made of high quality alloy steel,The surface is hardened by quenching.Fine processing, smooth transmission, low noise, carrying capacity, long life.Direct reducer to more effectively improve the energy transfer.

Electric control cabinet

Electric control cabinet equipped with Siemens PLC, Schneider Electric components, to achieve double shaft operation automation.Touch screen operation so that the whole machine programming, maintenance and repair becomes convenient,Customers can choose a soft start or VFD drive to start a smooth start.

Removable cutlery

Removable blade design can greatly shorten the blade replacement time.Through the release and locking bolts can easily complete removal and replacement of wear Blade.Broken different materials,Flexible with the corresponding number of claw blades,Can play the best machine shredding effect.

Mini model T-1200 (standard model for general reference)

| Model | T-1200 |

| Motor Power | 30+30 KW ... ( customizable) |

| Rotor Blade Qty | 24 pcs (more pcs also available) |

| Rotor Blade Thickness | 50mm (other thickness also available) |

| Blade Material | Sicr Cris H13 Ld ... (customizable) |

| Speed | 15-24rpm |

| Rotor Dia | 380mm (adjustable) |

| Chamber Size | 1000*580mm (adjustable) |

| Machine Size / mm | 4000*1400*2200 (depends) |

| Machine Weight | 6800 kgs (depends) |

Quick details

1. Lead time - 48 working days

2. Payment Term - 30% advanced payment once upon signing the

contract,70% balance payment before delivery.

3. Machine Installation

4. Our guarantee period is 12 months. Within the guarantee period the broken parts (excluding quick-wear parts) can be exchanged with our new parts if it is not caused by human factors. And technicians are available for solving big problems overseas(this situation never happened ). Beyond the guarantee period the broken parts dispatched are charged at cost price.

Other Applications

| A variety of containers | plastic beverage cans, plastic barrels, drums, crates, packaging barrels,PP bottle,PE/pet bottle. |

| E scarp | TV, washing machine, refrigerator shell, printer, keyboard, waster Microwave oven,waster computer,waster mouse,Circuit board. |

| Film | plastic film,HDPE film,PE film,PP film ... |

| Wood | wooden pallets, plastic pallets, forklift pallets,Used furniture |

| Rubber | waster wire, tires tires, truck tires |

| Garbage | Food waste,animal carcass, medical waste, garden garbage |

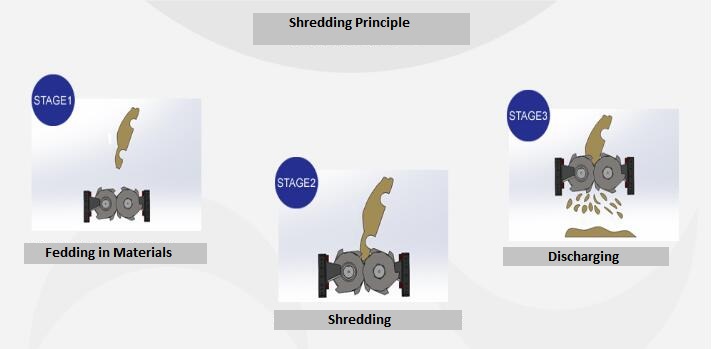

How does the machine work ?

Step 1. The material walk into the inner part of the breaking chamber through the feeding system or from hopper directly.

Step 2. The material is taken up by the barbed blade, pulled unceremoniously into the machine and then shredded between the blades on the two opposing shafts.

Step 3. The material is shredded into small pieces and discharged from the bottom part of the chamber box.

Service