Henan Yuanda Boiler Co., Ltd. |

|

95% High Efficiency Wns Natural Gas Diesel Oil Fired Hot Water Boiler

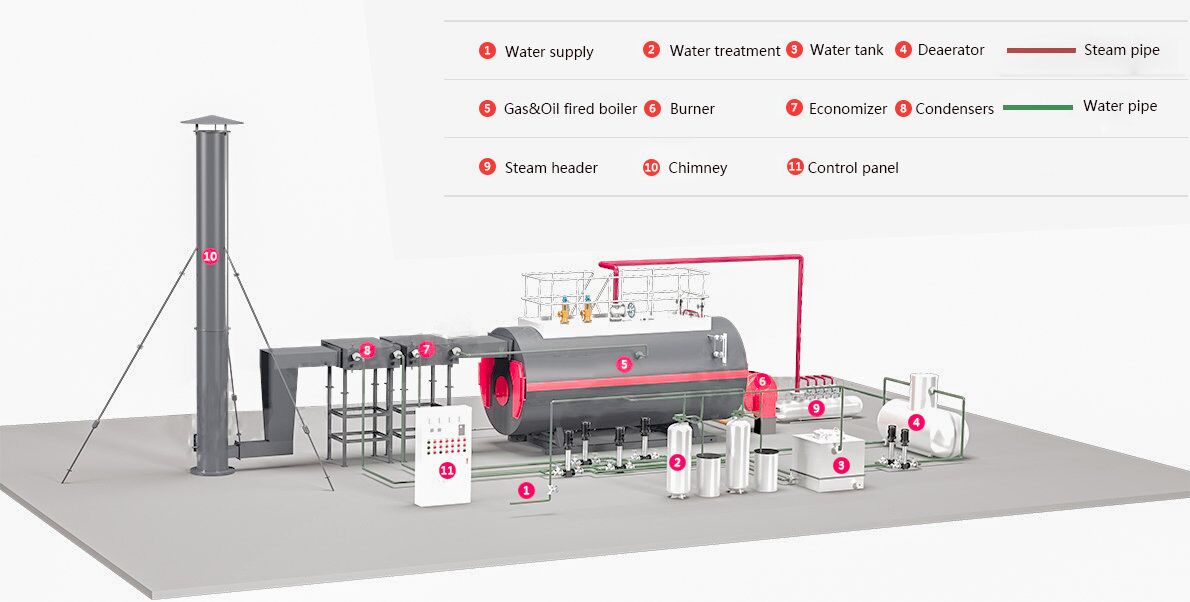

Oil Fired Hot Water Boiler General introduction

WNS series boiler is horizontal three pass fire tube hot water boiler.It equipped with good performance burner and advanced techniques.The burning control, water feed,programs run,etc,are full automatic.This boiler is safe and reliable, and also has the advantage of compact structure,simple operation,easy installation, high efficiency ,less pollution and noise,etc. It is widely used for factory, hotel, hospital, office building, etc.

1. Boiler type: fire tube, smoke tube boiler.

2. Fuel: natural gas, lpg, lng, cng, biogas,diesel, heavy oil.

3. Pressure: 0-16bar on option.

4. Structure: three pass, wet back, horizontal.

5. Boiler capacity: 0.7MW, 1.4MW, 2.8M, 4.2MW, 5.6MW, 7MW, 10.5MW,

14MW

6. Application: heating system for hotel, hospital, school,

swimming pool, greenhouse, residential area.

Advantages of Oil Fired Hot Water Boiler

1. The spiral furnace design

Increase the overall strength of the furnace,make compensation for

the heat exchange and shrinkage automatically,avoid the

in-perfection of welded sew crack due to the change of tube plate

heating stress.Therefore,boiler has strong adaptability about

various of fuel,for example,heavy oil,light oil,natural gas,city

gas.

2. Improve heat transfer technology

Apply the technology of heat transfer from “the light of Harbin

institute”.Adopt the design of efficient heat transfer screw thread

pipe and optimize the smoke speed.The output and heat efficiency of

boiler don’t decrease with the extend of operation time,thus

achieve a compact structure with 10% overload capacity.

3. Climate compensation, on-demand heating technology

Considering to the outside temperature and users’ heat

demand,boilers could control the water temperature in the support

of heat source efficiency automatically so that we achieve the goal

of on-demand heating and energy-saving heating.

Oil Fired Hot Water Boiler Technique parameter

| Boiler model | Rated capacity | Rated pressure | Rated Feed temp. | Rated Steam temp. | Thermal efficiency | Weight | Dimensions |

| t/h | Mpa | ℃ | ℃ | % | ton | mm | |

| WNS1-1.0-Y(Q) | 1 | 1 | 20 | 184 | 91 | 4.3 | 3561×1690×1910 |

| WNS 2-1.25- Y(Q) | 2 | 1.25 | 20 | 194 | 92 | 7.2 | 4111×1950×2199 |

| WNS3-1.25-Y(Q) | 3 | 1.25 | 20 | 194 | 92.1 | 8 | 4330×2248×2564 |

| WNS4-1.25- Y(Q) | 4 | 1.25 | 20 | 194 | 93 | 9.6 | 4732×2150×2448 |

| WNS5-1.25- Y(Q) | 5 | 1.25 | 20 | 194 | 93 | 12.5 | 5970×2360×2796 |

| WNS6-1.25- Y(Q) | 6 | 1.25 | 20 | 194 | 93.2 | 16.5 | 5500×2600×2990 |

| WNS8-1.25- Y(Q) | 8 | 1.25 | 105 | 194 | 93.5 | 24.8 | 6450×2800×3200 |

| WNS10-1.25- Y(Q) | 10 | 1.25 | 105 | 194 | 93.5 | 26.8 | 6800×2900×3394 |

| WNS15-1.25- Y(Q) | 15 | 1.25 | 105 | 194 | 93.5 | 38 | 7150×3200×3540 |

| WNS20-1.25- Y(Q) | 20 | 1.25 | 105 | 194 | 93.5 | 55 | 8200×3400×3826 |

Water treatment equipment Introduction

1. As we know, gas steam boilers need to configure water treatment

equipment. However, some people do not know why to configure.let’s

study together,what’s the specific role of water treatment

equipment?

The water injected into boiler contains lots of calcium and

magnesium and other cations. These cations are easy to form

precipitate under heating at high temperature.The precipitate will

attach to the inside of boiler.After long time operating, not only

affect the thermal efficiency of boiler,but also damage the inside

wall, thereby shortening boiler life and bringing economic loss to

users.

2. In general, if boiler doesn’t equip the water treatment device,

may bring some damage to the boiler as follows:

(1) Increasing fuel consumption volume.

(2) Shorten gas steam boiler life;

3. At last but not least,in daily boiler operation, you need to do:

(1) Detecting water quality of boiler regularly.

(2) Replacing the water treatment resin regularly, to ensure water

treatment effect;

How to choose oil fired hot water boiler ?

1. Determine evaporation;

Selection of the boiler hourly steam production must be greater

than the production needs of the steam, the production, the boiler

can be 70% -100% load state operation, are the best running state;

2. Determine using pressure;

Boiler use pressure determined by the production process,

selection, the boiler design pressure must be greater than the

actual operating pressure to ensure that the boiler below the

design pressure in the state of operation to ensure the safety of

the boiler to ensure the operating results;

3. Determine the auxiliary equipment;

After confirm boiler evaporation and using pressure, you need to

select the auxiliary equipment, what accessories equipment you

choose, directly determine the running effect of boiler effect,

also determine the price of boiler equipment;