Oil Filled Diffused Sillcon Pressure Transmitter Sensor For Water

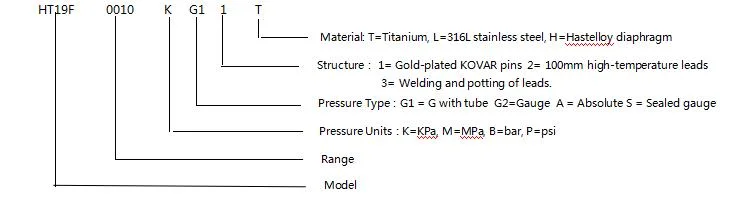

And Oil Test

19mm Silicon Piezoresistive Pressure Sensor

Introduction of Pressure Transmitter Sensor:

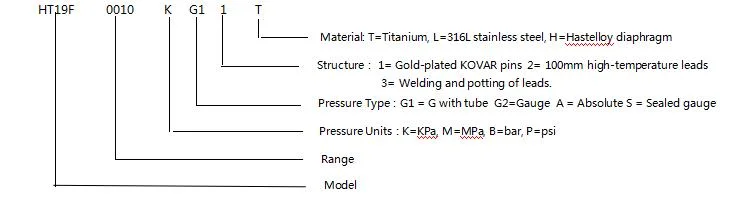

HT19F functions as a silicon piezoresistive pressure sensor ,with a

core consisting of a highly stable diffused silicon element,. It

effectively measures the pressure of liquids and gases by transmitting the pressure of

the tested medium to the silicon diaphragm through an isolation diaphragm and

silicon oil.The sensor's versatility finds extensive use in air compressors and

refrigerationsystems.

Product Features of Pressure Transmitter Sensor:

1.Utilizing advanced technology and 316L stainless steel housing,

along with materials such as titanium and Hastelloy for the diaphragm

2.Employing thick-film circuits for temperature compensation and

zero-point correction

3.outstanding reliability, repeatability, and stability

Applications of Pressure Transmitter Sensor:

1.Suitable for measuring non-corrosive gas and liquid pressure with

316L stainless steel compatibility

2.Applied in various industrial process sites, including petroleum,

chemical, metallurgy, power, and hydrology

3.Used in marine and aviation industries

4.Suitable for hydraulic and pneumatic control systems

5.Utilized in process control applications

Electrical performance of Pressure Transmitter Sensor:

1.Power Supply: ≤2mA DC (Typical 1.5mA DC)

2.Input Impedance:3KΩ~6KΩ

3.Output Impedance:2.5KΩ~6KΩ

4.Electrical Connection:Gold-plated Kovar pins or 100mm

high-temperature wires.

| Performance Parameters: |

| Range | Gauge(G) | 10KPa,20KPa,35KPa,100KPa,200KPa,350KPa,1000KPa,2000Kpa |

| Absolute(A) | 100KPaA,200KPaA,350KPaA,700KPaA,1000KPaA,2000KPaA |

| Sealed(S) | 3500KPaS,7MPaS,10MPaS,20MPaS.40MPaS.60MPaS.100MPaS |

| | Typ | Max | Unit |

| Nonlinearity | ±0.15 | ±0.3 | %F.S |

| Repeatability | 0.05 | 0.1 | %F.S |

| Hysteresis | 0.05 | 0.1 | %F.S |

| Zero Output | 0±1 | 0±2 | mV |

| Span Output | ≤20KPa | 50±10 | 50±30 | mV |

| ≥35kPa | 100±10 | 100±30 | mV |

| Temperature Error-Zero | ≤20KPa | ±1 | ±2 | %F.S |

| ≥35kPa | ±0.5 | ±1 | %F.S |

| Temperature Error-Span | ≤20KPa | ±1 | ±2 | %F.S |

| ≥35kPa | ±0.5 | ±1 | %F.S |

| Compensated Temp. | ≤20KPa | 0~50 | ºC |

| ≥35kPa | 0~70 | ºC |

| Operating Temperature | -20~80 | ºC |

| Storage Temperature | -40~125 | ºC |

| Allowable Overload | Take the smaller value between 3 times the full scale or 120MPa | |

| Burst Pressure | 5X the full scale | |

| Long-term Stability | 0.2 % | F.S/Year |

| Diaphragm Material | 316L | |

| Insulation Resistance | ≥200MΩ 100VDC | |

| Vibration | No change under conditions of 10gRMS, 20Hz to 2000Hz | |

| Shock | 100g,11ms | |

| Response Time | ≤1ms | |

| O-ring Seal | Nitrile ring or Fluoro ring | |

| Filling Medium | Silicon Oil | |

| Weight | ~ 28g | |

| The parameters are tested under the following conditions: 1.5mA @

25°C |

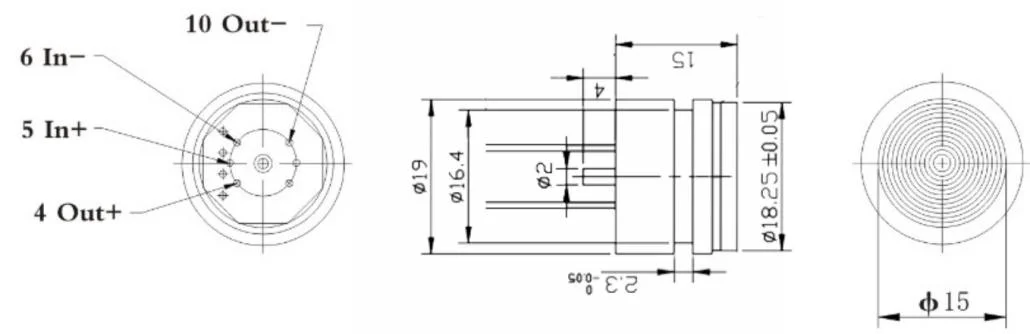

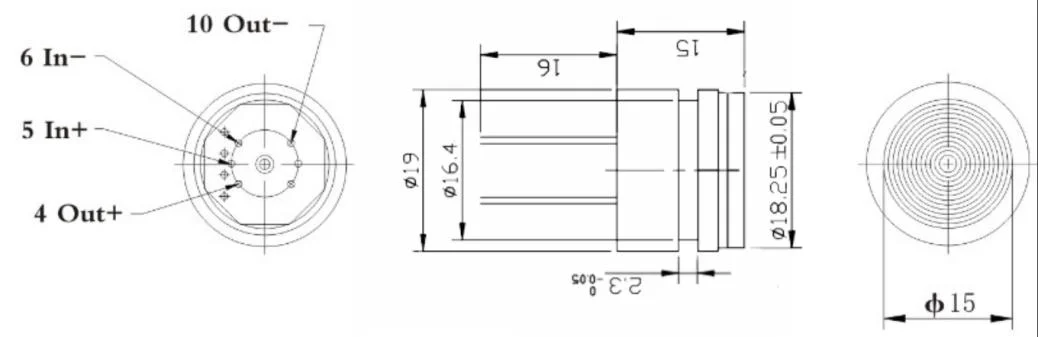

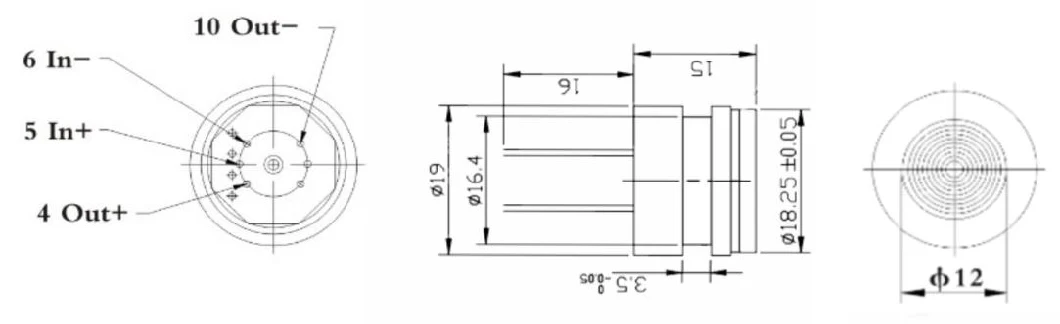

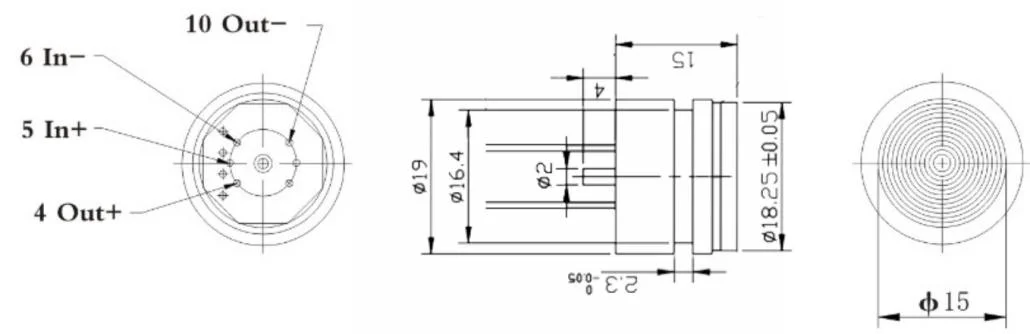

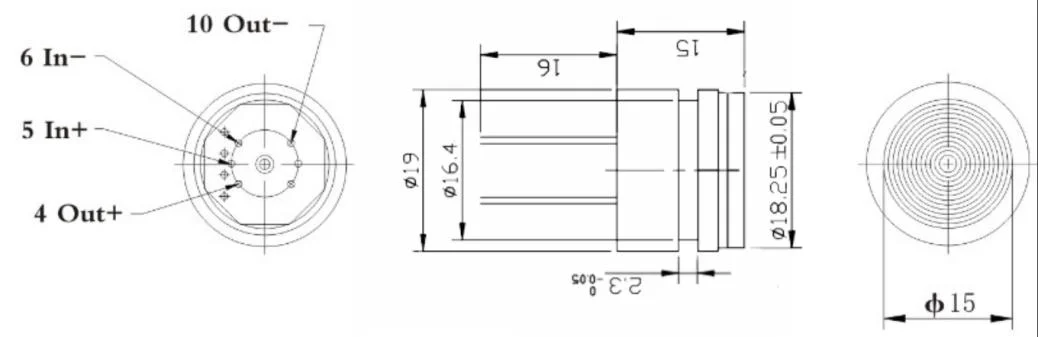

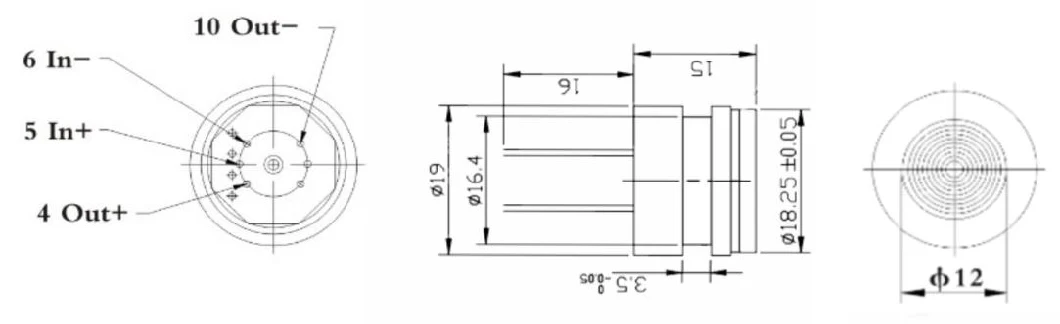

| Outline Construction |

| <3.5MPaS |  |

≥3.5MPaS

<40MPaS |  |

| ≥40MPaS |  |

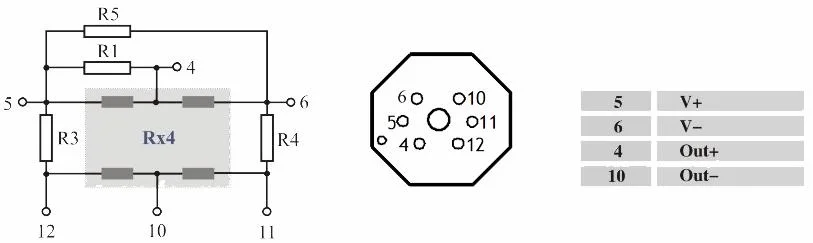

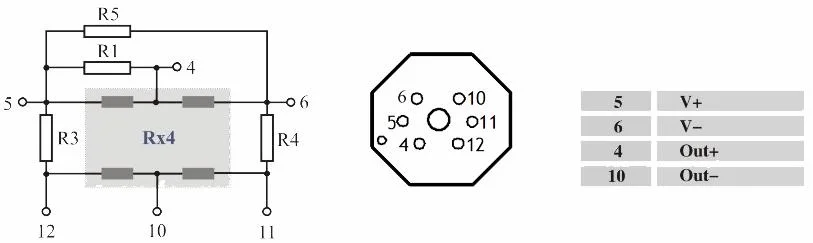

| Electrical connection and compensation |

|

1. Pay attention to the fit between the core size and the

transmitter housing during assembly to achieve the required airtightness 2. During the assembly of the housing, ensure it is aligned

vertically and apply even pressure to avoid jamming or damaging the

compensation plate.

3. If the measured medium is not compatible with the core diaphragm

and the housing material (316L), special instructions should be

provided when placing the order.

4. Avoid pressing the sensor diaphragm with hands or sharp objects

to prevent damage to the core due to diaphragm deformation or

piercing.

5. Keep the pressure port of the gauge pressure core open to the

atmosphere and prevent the entry of water, water vapor, or

corrosive media into the core negative pressure chamber.

6. If there are any changes to the pin leads, follow the label on

the actual core for reference.