Hebei Qijie Wire Mesh MFG Co., Ltd |

|

Verified Suppliers

|

|

| Model | QJ-04 | Welding electrodes | 48pcs |

| Wire diameter | 2.5mm-6mm | Welding speed | 50/75times/min |

| Longitude wire space | 50mm-300mm | Rated electrical power | 125kva*6pcs |

| Cross wire space | 25/12.5mm-300mm | Needed power | Min.160kva |

| Width of mesh | Max.2.5m | Weight | 4.2T |

| Length of mesh | Max.6m | Overall size | 5.4m*3.2m*1.7m |

| Longitude wire feeding | Pre-straightened&pre-cut | Cross wire feeding | Pre-straightened&pre-cut |

Wire diameter: 1.8-3mm/2-3.5mm/2-4mm

Longitude wire space: 50-200mm

Cross wire space: Min.25mm/12.5mm

Mesh width: Max.1.2m, max.1.6m

Longitude wire feeding: automatic from coils

Cross wire feeding: automatic from coils

Mesh pulling: Panasonic servo motor

Welding speed: 60-120 times/min

Mesh type: panel mesh or roll mesh

Notes:when wire diameter is 2.5mm-5mm,the minimum longitude wire space is

50 mm.One transformer controls 8 welding electrodes,you can use max

48 pcs. when wire diameter is 5mm-6mm,the minimum longitude wire

space is 100mm.One transformer controls 4 welding electrodes,you

can use max 24 pcs.

Application materials : welding machine is good at welding various

metal wire : stainless steel wire , low carbon steel wire , round

steel bar, ribbed steel bar

Application mesh panel : welded mesh panel widely used as reinforce

mesh panel for building, construction ;railway wire mesh fence,

security fence and others.

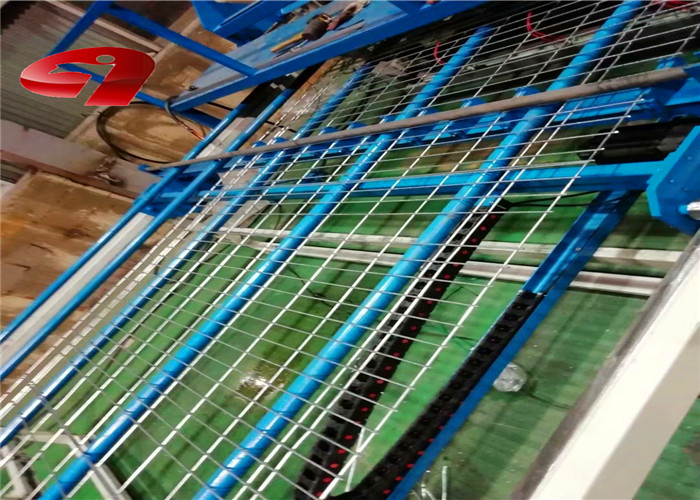

Welded fence mesh panel welding machine

Fence mesh panel welding machine, also called security fence

machine, anti-climb fence welding

machine, used to make fence mesh, road mesh, reinforcing mesh,

shelf, explosion-proof wall etc.

Machine Image

Panasonic, Schneider, ABB, SMC, Igus electric components.

Touch screen interface.

PLC control of cross wire space and welding current.

Pre-straightened & pre-cut wires.

Panasonic servo technology for mesh pulling.

Pure welding electrodes, upper Φ20*120mm, lower 20*20*20mm.

Water-cooling system.

Brake motor & reducer connect the principal axis directly.

High precision mesh

Fence Mesh Welding Machine Function features and advantages:

1. This machine adopts electrical & electronic synchronous

control technique, both separate-phases welding and welding time

composed of digital and integrated electric circuit. The input

panel has two types touch screen and button, more intelligent and

rational, once pressing, and separate welding.

2. The welding power is electric power. The cross wire is fed from

hopper driven by stepper motor, and the line wire is fed by brake

motor driven car and the mesh is pulled by the stepper motor driven

car.

3. The cross and the line wires are both pre-straightened and

pre-cut by the special straightening and cutting machine.

4. The biggest advantage of the machine is that there is different

cross spacing in the same mesh.

5.The welding electrodes and transformer are equipped with the

water cooling system,thus prolong the machine life and working

time.