Hebei Qijie Wire Mesh MFG Co., Ltd |

|

Verified Suppliers

|

|

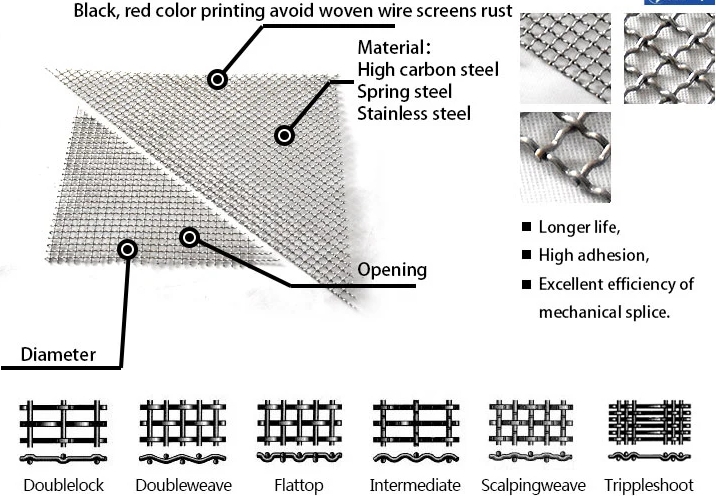

High Tensile 65mn 45# Manganese Steel Wire Woven Quarry Rock Square Hole Crimped Wire Screen Mesh

Heavy duty crimped wire mesh are the most widely used screens in the aggregate and mining

industries, due to their high screening area, precision and price

ratio. The Crimped wire mesh (mining screen wire mesh, square wire

mesh) are manufactured in different geometries (square or slotted

meshes) and different weaving styles (double crimped, flat mesh,

etc.).

Crusher screen wire mesh is also called vibrating screen woven mesh, crusher woven wire

mesh, quarry vibrating screen mesh, quarry screen mesh etc. it is

wearable resistance, high frequency and longer life. Manganese

steel vibrating screen mesh is made of the high tensile manganese

steel, and the most widely used and common is 65Mn steel.

Features: Weaving with pre-crimped wire, offering strong structure,

substantially woven, durable, uniform cell, heat-resisting,

corrosion-resisting, abrasion-resisting

Crimped wire mesh shape: v-shaped, u-shaped

Angle: 30 degrees, 45 degrees

Pre-crimped wire mesh is made of wire diameters ranging from 1.5mm to 6 mm. It can be used for windows, partitions, roasting of meat and flour sieving or mine screens.

In the pre-crimping process, the wire is first formed (crimped) in precision machines using rotary dies that precisely define the spacing of the wires. This insures that the wires are locked firmly together at the intersections. The pre-crimped wires are then assembled in custom designed screen assembly machines (looms).

When the open area is important, extra crimps between the intersections provide a more rigid weave and provide locking and tightness for light wires in relation to the large openings.

Due to the crimping process, the mesh have very accurate and consistent openings and are woven after crimping. It is typically preferred for vibrating screens and many other applications where sizing is critical.

| Material | Wire Gauge | Hole Size |

|---|---|---|

| Stainless (SUS 304#) | 1.2m/m~12m/m | 10mm - 100mm |

| Hot dip galvanized | 1.2m/m~12m/m | |

| Galvanized | 1.2m/m~12m/m | |

| Customization Was Available | ||

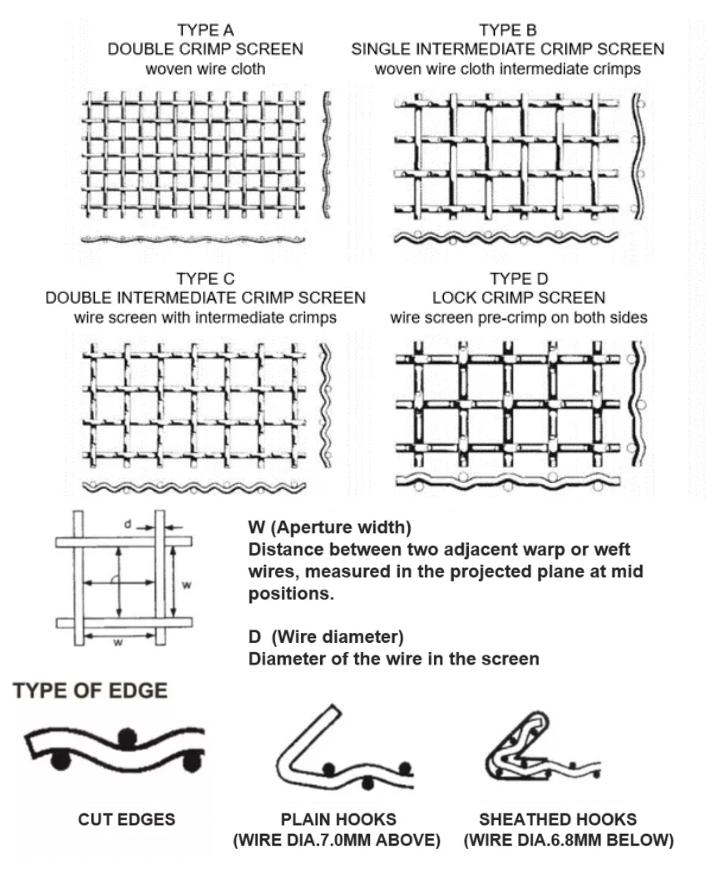

1. Double Crimp Woven Wire

Used for medium to heavy wire in relation to screen opening size.

2. Lock pre-crimp mesh

Unlike plain crimped mesh, lock crimped mesh is characterized by

straight sections of wire connected by a well defined bump at the

wire intersections, such a manner to actually lock the wires

together, offering further assurance of no wire movement. Our lock

crimp wire mesh is good in quality and competitive at price.

3. Flat Top Woven Wire

Flat top is similar to the lock crimp, but all of its crimping is

offset to one side of the material. This creates a smooth top

surface-with no high points-as all wires are woven on a single

plane. Its bottom side, however, has crimp bumps approximately

twice the height of lock crimp bumps. Flat top was originally

created to allow for the smooth flow of materials over the surface

and provide a flat face for use as backer screens. Flat top is

ideal for aggregate sizing and sorting, agriculture, filtration,

and heat-treating applications.

4. Intermdiate Crimp Woven Wire

Used in coarse weaves of lighter gauge woven wire to provide

greater stability, tightness of weave and maximum rigidity. Very

common in wire mesh openings larger than 1/2" (12.7mm).

| Name | Heavy duty wire Crimped Wire Mesh.Mine Mesh. Vibratingscreen mesh |

| material | 65Mn,45#,50#,55#,60#,70#,72A, 304, 316, 316L |

| wire | 0.8mm-12.7mm |

| Opening | 2mm to 100mm |

Applications

Used for

Packing

Packing: In rolls, wrapped with waterproof paper then covered with

hessian-cloth. Special packing may be arranged if necessary.