Jiangsu Yutong Drying Engineering Co.,ltd |

|

Verified Suppliers

|

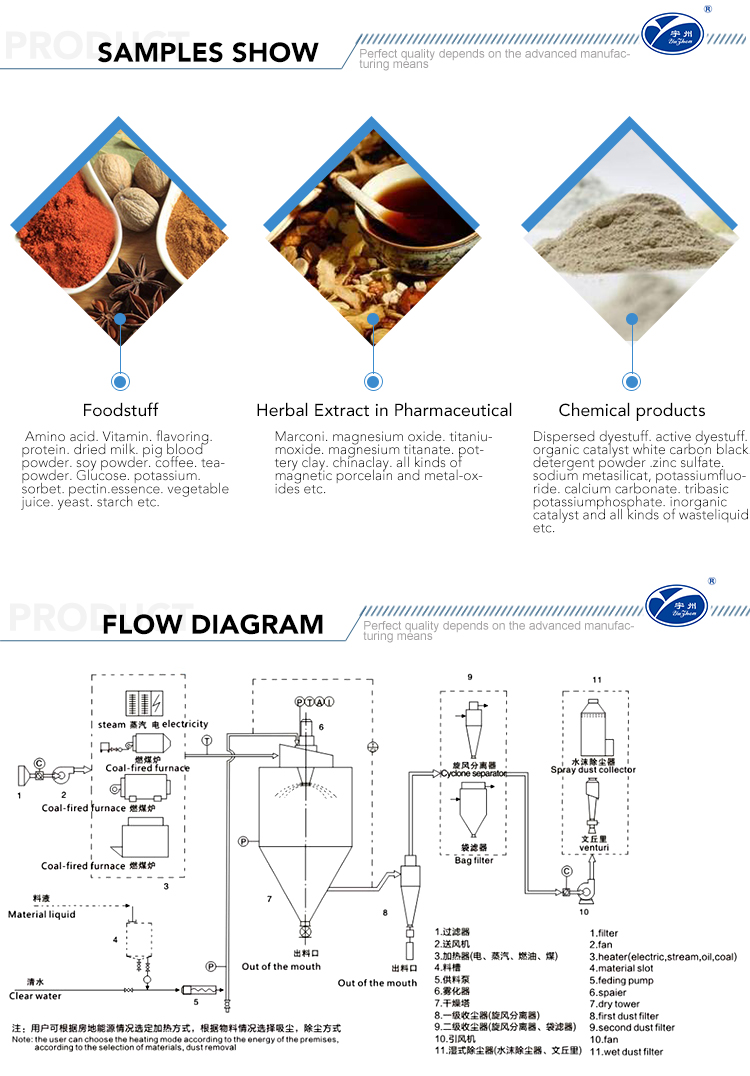

Substitute Milk Powder Centrifugal Spray Drying Equipment In Foodstuff

Model | 5 | 25 | 50 | 100 | |||

Inlet temperature | 140-350 degree automatical control | ||||||

Outlet temperature | 80-90 degree automatical control | ||||||

Max water evaporation capacity | 5 | 25 | 50 | 100 | |||

Centrifugal spray head drive | compress air drive | mechnical drive | |||||

Speed | 25000 | 18000 | 18000 | 18000 | |||

Spray disc diameter | 50 | 100 | 120 | 140 | |||

Heat source | Electric | Electric +steam | electric +steam Gas Fuel, as customer requirement | ||||

Max powder of electric heating | 9 | 36 | 63 | 81 | |||

Outline dimension | 1.8x0.93x2.2 | 3x2.7x4.26 | 3.7x3.2x5.1 | 4.6x4.2x6 | |||

Collection powder recovery | >95 | ||||||