Chengdu Yongyi Pump Industry Co., Ltd. |

|

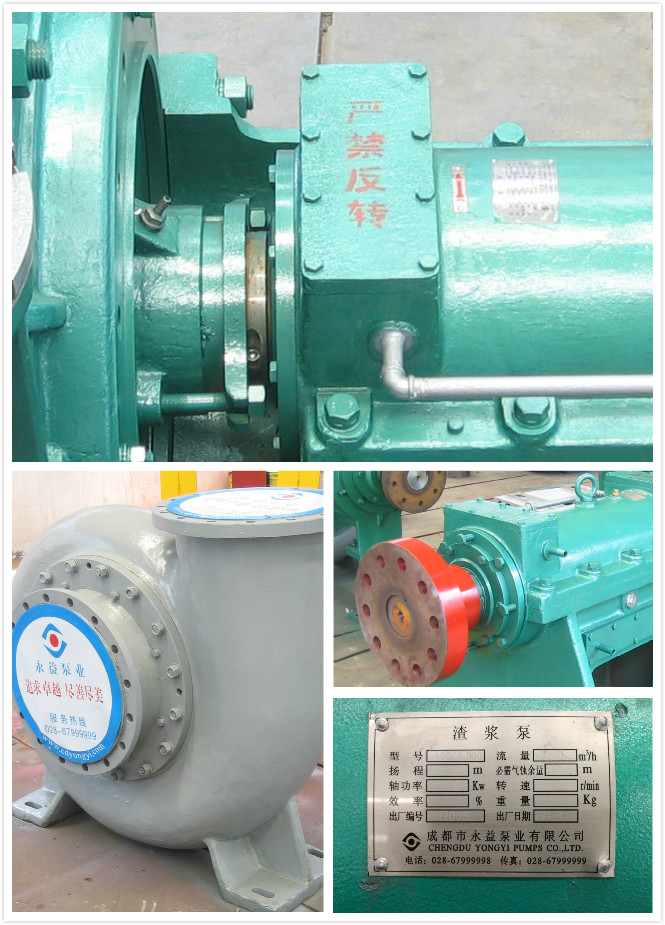

Metal ZJ High Pressure Slurry Pump Horizontal Split Case with Interchangeable Spare Parts

Product Description

ZJ-series pumps are single-stage heavy duty slurry pumps, with easily-replaceable wear parts and re-adjustable wear plate. ZJ pumps adopt advanced design, with only metal linings, and is very widely used for abrasive applications. The pump is energy saving and cost reducing, the pump has advanced water conservancy,so the efficiency is higher than other pumps.

Details

Application

Sludge and Solids

Sand and Aggregate

Mining Industries

Ash Handling

Cyclone Feeds

Pulp and Paper

Abrasive Slurries

Coal Preparation

Minerals Processing

Aggregate Processing

Specification Data

Discharge Size:20mm~350mm

NPSH:0m~3m

Inlet Size:32mm~400mm

Allowed Max Particle Size:20 mm

Capacity:4 ~ 3000 m³/h

Seal Type:step-down dynamic seal

Head:10 ~ 130 m

Pump Weight:up to 3000kg

Maximal Efficiency:70%

RPM:1450 r/min

Production Process

Optional Material

| IMPELLERS | CASING | COLUMN | DISCHARGE | SEALS | |

| Standard | High Chrome Alloy Rubber | High Chrome Alloy Rubber | Mild Steel Mild Steel Rubber Lined | Mild Steel Mild Steel Rubber Lined | Natural Rubber Rubber |

| Options | Butyl EPDM Hypalon Polyurethane 316 SS W 151 | Neoprene Butyl EPDM Hypalon Nitrile 316 SS W 151 | Neoprene Butyl Nitrile 316 SS | Neoprene Butyl Nitrile 316 SS | Nordel Neoprene Viton Hypalon Butyl EPDM |