Chengdu Yongyi Pump Industry Co., Ltd. |

|

Single-stage Circulating Centrifugal Pump Sustainable Corrosive Resistant Chemical Pump

Application

Product Summary

Diameter: 200mm~470mm

Structure: single-stage pump

Capacity: 8 ~ 800 m³/h

Head: 10 ~ 90 m

Maximal Efficiency: 70%

NPSH: 1.4m~4.5m

Allowed Max Particle Size: 20 mm

RPM: 1450 r/min

Impeller Type: closed/ half open

Bearing box

WDL series corrosion-resistant and wear-resistant vertical pumps are equipped with axial adjustment devices. After the flow parts have some wear and corrosion, the gap between the impeller and the pump body can be adjusted through the hexagonal top screw on the bearing box to prolong the service life.

Bearing body

The bearing body uses a double bearing structure to bear the radial and axial forces. The WDL-series pump is equipped with a cylindrical roller bearing with radial force at the lower end. The upper end of the pump is equipped with double row angular contact ball bearings to bear the axial force and partial radial force.

Technical Parameter

| model | flow (m³/h) | Head (m) | Rotating speed (r/min) | Highest efficiency (%) | pump head weight KG | Submerged depth mm | Shaft component |

| 40WDL-250 | 8-20 | 15-28 | 1450 | 39 | 620 | 1300/1000 | 100 |

| 40WDL-310 | 8-40 | 23-42 | 1450 | 45 | 692 | 1300/1000 | 100 |

| 40WDL-350 | 8-45 | 35-54 | 1450 | 37 | 870 | 1300/1000 | 120 |

| 50WDL-250 | 10-30 | 15-28 | 1450 | 40 | 642 | 1300/1000 | 100 |

| 50WDL-310 | 15-60 | 25-42 | 1450 | 45 | 705 | 1300/1000 | 100 |

| 50WDL-350 | 15-70 | 35-54 | 1450 | 50 | 886 | 1300/1000 | 120 |

| 50WDL-400 | 20-75 | 50-75 | 1450 | 45 | 961 | 1300/1000 | 120 |

| 65WDL-250 | 30-70 | 15-28 | 1450 | 48 | 652 | 1300/1000 | 100 |

| 65WDL-310 | 30-90 | 25-40 | 1450 | 57 | 905 | 1300/1000 | 120 |

| 65WDL-350 | 40-100 | 35-54 | 1450 | 59 | 915 | 1300/1000 | 120 |

| 65WDL-400 | 50-120 | 45-75 | 1450 | 55 | 1008 | 1300/1000 | 120 |

| 65WDL-450 | 50-120 | 70-95 | 1450 | 52 | 1075 | 1300/1000 | 120 |

| 80WDL-250 | 70-100 | 15-25 | 1450 | 61 | 652 | 1300/1000 | 100 |

| 80WDL-310 | 70-120 | 25-40 | 1450 | 62 | 935 | 1300/1000 | 120 |

| 80WDL-350 | 70-160 | 35-52 | 1450 | 65 | 940 | 1300/1000 | 120 |

| 80WDL-400 | 70-160 | 50-75 | 1450 | 62 | 1068 | 1300/1000 | 120 |

| 80WDL-450 | 70-160 | 70-95 | 1450 | 60 | 1100 | 1300/1000 | 120 |

| 100WDL-310 | 100-150 | 20-38 | 1450 | 65 | 960 | 1300/1000 | 120 |

| 100WDL-350 | 100-220 | 35-50 | 1450 | 65 | 970 | 1300/1000 | 120 |

| 100WDL-400 | 100-220 | 40-72 | 1450 | 65 | 1125 | 1300/1000 | 120 |

| 125WDL-310 | 120-260 | 18-36 | 1450 | 67 | 1025 | 1300/1000 | 120 |

| 125WDL-350 | 120-300 | 35-50 | 1450 | 68 | 1035 | 1300/1000 | 120 |

| 125WDL-400 | 140-350 | 45-70 | 1450 | 70 | 1206 | 1300/1000 | 120 |

| 125WDL-450 | 150-360 | 65-90 | 1450 | 67 | 1497 | 1300/1000 | 140 |

| 150WDL-310 | 200-400 | 18-35 | 1450 | 72 | 1127 | 1300/1000 | 120 |

| 150WDL-350 | 200-450 | 25-48 | 1450 | 75 | 1175 | 1300/1000 | 120 |

| 150WDL-400 | 200-450 | 40-65 | 1450 | 73 | 1668 | 1300/1000 | 140 |

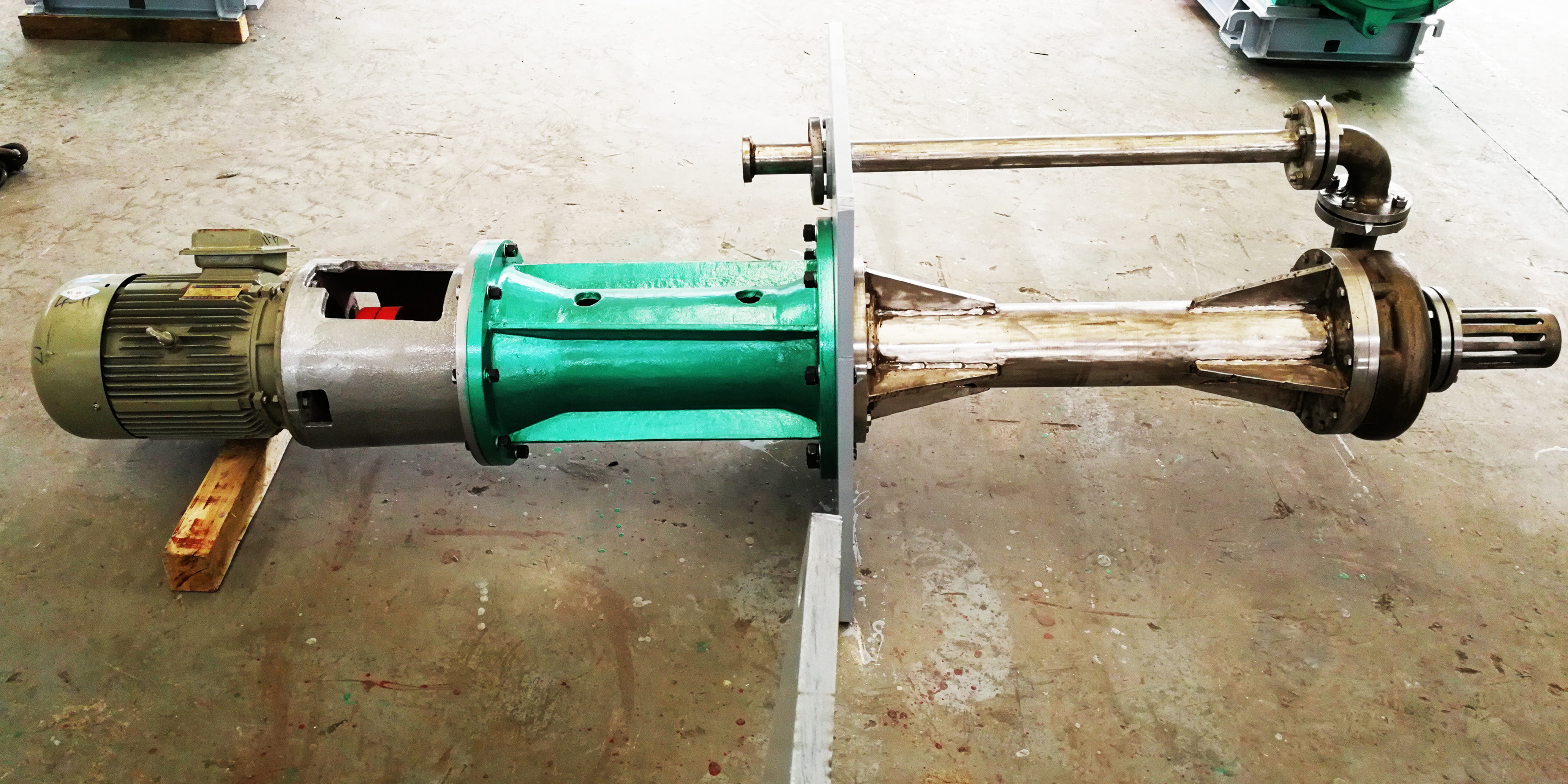

Product Picture

Main Usage

| ♦ chemical plants, power stations |

| ♦ iron and steel metallurgy enterprises |

| ♦ paper mills |

| ♦ petrochemical refineries |

| ♦ chemical factories |

| ♦ construction of thermal power plants and power stations |

| ♦ textile mills, sugar factories |

| ♦ mines |

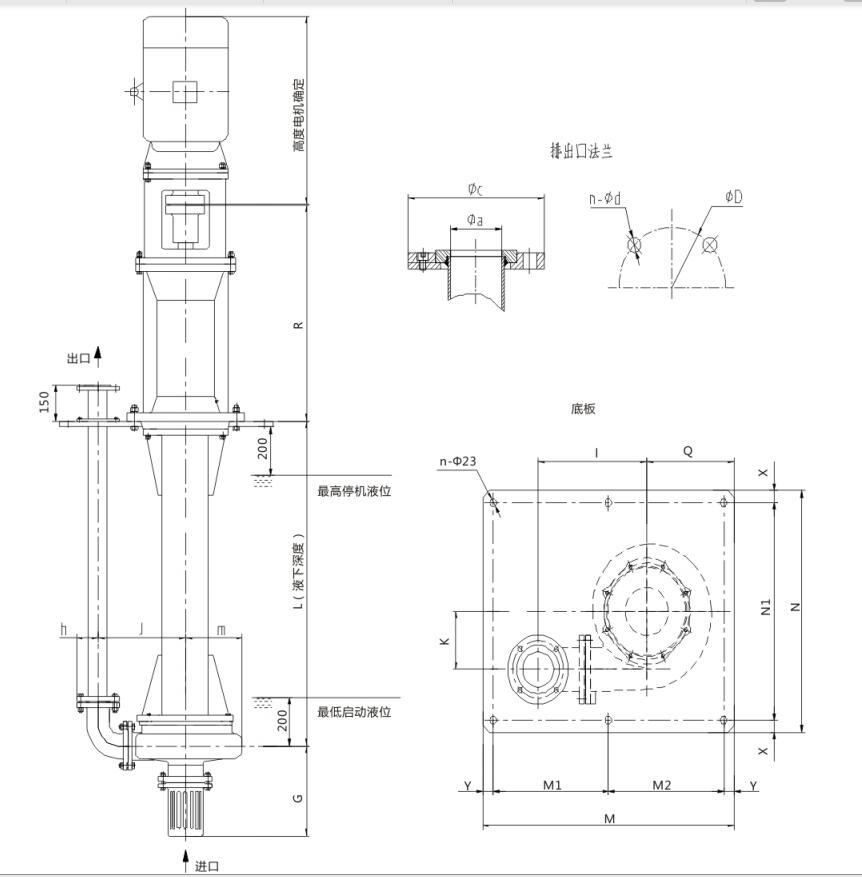

Installation Dimension

FAQ

1. Q: Are you a manufacturer or trading company?

A: We are a manufacturer established in 1995, professional

manufacturer of chemical-process pump and energy-saving mixer with

more than 20-year experience.

2. Q: What's your delivery time?

A: The batch order will be shipped within 40 working days after

receiving deposit.

3. Q: What's your warranty service policy?

A: 12 Months for all products, and some products warranty is

24months.

4. Q: What information I need to offer for quotation?

A: Medium: ____________

PH: ________

Specific Gravity: _______

Temperature: _________

Capacity/Flow: ________m3/h Head:

_________m

Voltage: ____________V

Frequency: _________Hz

Power:_____________KW

5. Q: What is your minimum quantity?

A: One set is also welcomed to us.