HENAN ZG INDUSTRIAL PRODUCTS CO.,LTD |

|

Verified Suppliers

|

|

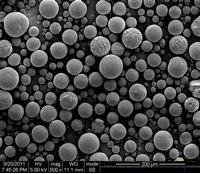

SPHERCIAL ALUMINA POWDER FOT HIGH THERMAL CONDUCTIVE MATERIAL

Sphercial Alumina Powder Fot High Thermal Conductive Material

This product is a spherical alumina powder with high globularity with high thermal conductivity, developed by high temperature melting technologies and indicates excellent characteristics for rubber and plastic filler and ceramic base material.

Specifications:

Type | D50(um) | S.S.A.(m2/g) |

SA-05 | 5±1 | 0.60 |

SA-10 | 10±2 | 0.50 |

SA-20 | 20±3 | 0.40 |

SA-30 | 30±3 | 0.30 |

SA-40 | 40±5 | 0.20 |

SA-70 | 70+/-6 | 0.12 |

Physical Property:

| Appearance | White powder |

| Specific Gravity (g/cm3) | 3.60 |

| Melting point (℃) | 2050 |

| Moisture (%) | ≤ 0.05 |

| EC(uS/cm) | ≤ 10 |

| PH | 7.0±0.5 |

| α-Al2O3 Cotent(%) | ≥ 90 |

| Spherical particles ratio(%) | ≥ 95 |

Chemical Property:

| Type | Chemical Composition | ||||||

| Al2O3% ≥ | SiO2% ≤ | Fe2O3% ≤ | Na2O%≤ | K2O% ≤ | MgO%≤ | CaO% ≤ | |

| SA-05 | 99.0 | 0.05 | 0.05 | 0.03 | 0.02 | 0.01 | 0.01 |

| SA-10 | 99.0 | 0.05 | 0.05 | 0.03 | 0.02 | 0.01 | 0.01 |

| SA-20 | 99.0 | 0.05 | 0.05 | 0.02 | 0.01 | 0.01 | 0.01 |

| SA-30 | 99.0 | 0.05 | 0.05 | 0.02 | 0.01 | 0.01 | 0.01 |

| SA-40 | 99.0 | 0.05 | 0.05 | 0.02 | 0.01 | 0.01 | 0.01 |

| SA-70 | 99.0 | 0.05 | .05 | 0.02 | 0.01 | 0.01 | 0.01 |

Character:

2. High thermal conductivity: High filling density enables production of compounds with higher thermal conductivity and higher heat dissipation rate compared to crystalline silica.

3. Low abrasivity: Due to its Spherical shape, less-wearing of kneading machines, forming machines and dies.

Applications:

1. Filler for heat sink sheet, filler for heat dissipation board (MC board), heat dissipating

grease, phase change sheet

2. Filler for semiconductor sealing resin

3. Silicone-based heat dissipating adhesive, filler for compound

4. Ceramic filler