Henan Jinzhen Boiler Co., Ltd. |

|

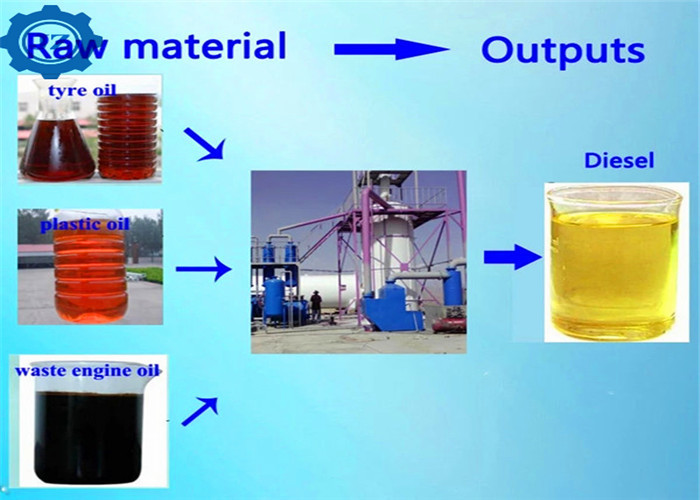

5TPD 10TPD 20TPD Used Oil Refining Machine Waste Engine Oil Diesel

Distillation Plant

Waste / used engine oil catalyst refinery equipment for diesel

Pyrolysis oil can be refined into valuable diesel oil through

catalytic cracking and high temperature distillation technology. It

is a method of separating mixtures based on differences in

volatilities of components in a boiling liquid mixture. After being

distilled by the distillation plant, the oil may have dark color

with bad smell, then we suggest to deep purify the oil, with

matched color and smell removal system, you will get clean diesel

oil as final products with beautiful light yellow color.

| Item | Specification | |

| Input-Raw Materials | Waste engine/motor oil/Plastic pyrolysis oil/Tire pyrolysis oil/Lubrication oil | |

| Average out-put oil rate | 85%-90% | |

| End products | Diesel oil, waste gas, slag | |

| Structure form | Horizontal | |

| Operating pressure | Constant pressure | |

| Heating material | Coal, charcoal, fuel gas, fuel oil | |

| Model(Diameter*Length)(mm) | Reactor size | Capacity |

| D1500*L3000 | 3 Ton/Day | |

| D2000*L5000 | 5 Ton/Day | |

| D2800*L6000 | 10 Ton/Day | |

| Material of reactor | boiler plate | |

| Thickness of reactor | 16mm, 18mm | |

| Mode of cooling | Circulating water cooling | |

| Space needed | Length: 30m, Width :10 m at most | |

| Power consumption | Average 15 KW/h | |

| Technical Specification | |

| Adopt high pressure and temperature resistance steel plate to ensure longer service life. For some speical raw material , we use special steel plate |

| High efficiency discharging | Adopt screw converyor discharging device , discharge carbon black in sealed condition , no pollution and save labour and time . |

| Integrated condensing device | All of the condensing parts have been installed together before delivery from factory , save installation time and ensure welding quality |

| Labour Saving | Auto feeder machine to feed raw material automatically , save labour and time. |

| Motor & Valve | All of the motors can be customized.All of the valves use stainless steel. |

| Adopt 3 layers of ceramic packing dedusting device and water spray , finally no black smoke discharged out. SGS emission report provided. |

| Safety devices | Alarm , auto pressure releasing device , and anti back fire device , vacuum pump to ensure the machine working smoothly. |

The unique advantages of waste engine oil distillation machine

Two products can be obtained from the waste oil distillation plant, 80%-85% diesel, 15%-25% asphalt. For the 80-85% diesel oil, you can used it into heavy machinery, gernerator, and boiler. For the 15%-25% asphalt, could be used for paving, or directly sold to asphalt refineries for further refining.

| No. | End Production | Yield | Usage |

| 1 | Diesel | 73% | Used for diesel engine |

| 2 | Gasoline | 12% | Used for gasoline engine |

| 3 | Residue Oil | 9% | * Feeding into Pyrolysis Machine for second Pyrolysis * Sold directly for building road |

| 4 | Non-Condensible Gas | 3% | Recycle as Heating fuel after treated by Gas-treatment System |

| 5 | Other | 3% | * Water and impurity 2% * Loss 1% |

Working process of waste engine oil distillation machine

1. Heat the heat conduction oil with the heat conduction oil

furnace;

2. The heat conducting oil flows into the coil in the distillation

reactor and heats the waste engine oil in the distillation reactor;

3. When the waste engine oil is heated to a certain temperature,

the reactor is directly heated with fuel. As the temperature

increases, the waste engine oil produces oil and flows into the

buffer tank. The odorous light components in the waste engine oil

can be distilled and collected into the distillation tank.

4. The oil gas from the buffer tank enters the catalytic tower. In

the catalytic tower the macromolecular oil gas are broken down into

smaller molecules

5. Oil gas of small molecules enter the cooling system through the

catalytic tower and are cooled into liquid oil;

6. After the oil gas steam out, the distillation reactor memory has

plenty of hot asphalt, which can be extracted by the asphalt pump.

After-sales service

1. Delivery time

It will be 20-25 days after we receive the deposit.

2. Warranty

The warranty period for reactor and other parts except spare parts is 1 year. The problem caused by wrong operation of workers shall not be responsible by our company.

3. Installation and Training

Our company will send one technician for each set of machine for guiding your installation, testing the machine and training your worker.

We have a professional customer service process to ensure customers' satisfaction from contact us to machine installation and after-sale service. If you have any question about the waste oil distillation plant, please contact us in time and you will get a satisfactory solution!

FAQ of waste engine oil distillation machine

Q: Are there any bad smell or odor from waste tyre oil distillation equipment while distillation system is working?

A: There will be no smell at all as the gas produced by waste oil distillation plant will be purified by our exclusive tail gas purification unit before emission.

Q: What is the yield of this waste tyre oil distillation equipment?

A: Typically the yield of our waste oil distillation plant is between 85-90% (depending on variations of water content, light HC and others ingredients from waste oil.)

Q: How many areas are required to build the waste tyre oil distillation equipment?

A: The land area required usually depends on the capacity of your plant. We can calculate the area needed and give you the plant designs.

Q: What is the warranty of the waste tyre oil distillation equipment?

A: 12 months free guanantee and life long standard paid service.

Q: Can you install the production line and train our stuffs?

A: Yes we can. We'll send engineers to help you install the waste

oil distillation plant and train your workers until the machine is

skillfully operated.