Henan Jinzhen Boiler Co., Ltd. |

|

Manual Operation Type Biomass Wood Chips Pellet Coal Fired Steam Boiler for Wood Processing plant

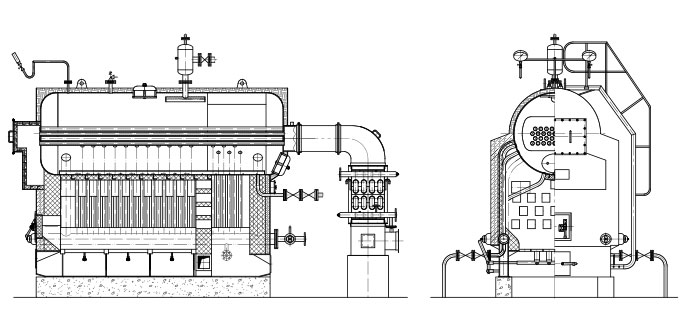

DZH horizontal steam boiler is a horizontal three-return water-fire tube hybrid boiler with threaded smoke pipe arranged in the boiler barrel.The left and right sides of the furnace are equipped with light tube water-cooling wall.Using light mobile grate, manual feeding, equipped with blower, induced fan for mechanical ventilation.The front and rear arch of the furnace adopts a new energy-saving technology.After the fuel is scattered on the grate and burned in the furnace, the flame passes through the rear arch refraction and turns upward to the front smoke box through the burnout chamber on both sides of the body. Then, the front smoke box folds back to the inner tube of the boiler, and enters the economizer through the rear smoke box. Then, it is pumped by the induced fan and discharged to the atmosphere through the flue to the chimney.

1. Model:DZH

2. Steam Capacity: 500kg/hr-4ton/hr

3. Design pressure:0.7Mpa(7bar), 1.0Mpa(10bar), 1.25Mpa(13bar),1.6Mpa(16bar)

4. Stem temperature: 184 °c,194°c, 204°c

5. Design fuel: Biomass pellet,wood sawdust, bamboo chip, wood block, straw

6. Structure: horizontal water-fire tube, single drum

7. Type: DZH manual coal feed type coal fried boiler

8. Application: medicine, chemical, light industry, textile, building material, cultivation, food and beverage, plastic foam, printing, dyeing and washing, rubber processing, paper products,wood processing, hotel, clothing and leather manufacturer etc

Structure

Combustion process:

The fuel enters the furnace and burns on the grate. The flue gas from the production enters the convection tube bundle on both wings along the bottom of the boiler barrel through the smoke outlet on the middle partition wall, enters the threaded smoke pipe through the front smoke box, passes through the dust collector, and is pumped and discharged into the atmosphere through the chimney by the induced draft fan.

Technical characteristics

11. High Thermal Efficiency

1.1 The spirally corrugated tube strengthen the heat transfer,

improve thermal efficiency. The flue gas has the foundation of

disturbance, avoid ash depositing in tube.

1.2 The furnace wall was poured entirely by the heat-resistance

concrete and high-temperature-resistance refractory brick, and the

boiler shell uses aluminium silicate board for heat preservation,

low heat loss.

1.3 Equip with economizer, make full use of the heat of flue gas,

decrease the exhaust smoke temperature, increase thermal

efficiency.

2. Anti-coking

2.1 For the easy coking biomass fuels, increase the size of

furnace, large space to achieve sufficient combustion.

2.2 Adopt unique double secondary air design, improve the ignition

condition of biomass fuels, sufficient air supply to make sure the

high combustion efficiency.

3. Avoid Bulging

The riser tube bundle under the drum, remove the dead water region

at the bottom of drum, sludge is not easy for depositing, the high

temperature area of drum has better cooling, prevent bulging.

4. Avoid Tube Plate Cracking

4.1 The boiler adopt arched tube plate and spirally corrugated

tube, change the quasi-steel body into quasi-elastic body

structure, reduce stress.

4.2 Arrange two sides gas duct in drum, the smoke gas could enter

into the front smoke chamber smoothly, the temperature of tube

plate is lower than 600℃, avoid cracking leaded by high

temperature.

5. Sufficient Output

Adopt horizontal type three pass structure and large furnace, to

ensure the sufficient combustion, and the boiler could absorb the

thermal expansion effectively. The large diameter boiler drum

increase the radiant heating surface, to ensure the sufficient

output.

6. Environmental Protection

6.1 The biomass fuels do not content sulfur, do not pollute the

environment, and the cost of biomass fuels are low.

6.2 The splayed wall and smoke outlet have the function of dust

removal, decrease the concentration of smoke emission.

| Model Item | DZH0.5-0.7-AII DZH0.5-1.0-AII | DZH1-0.7-AII DZH1-1.0-AII DZH1-1.25-AII | DZH2-0.7-AII DZH2-1.0-AII DZH2-1.25-AII DZH2-1.6-AII | DZH4-1.25-AII DZH4-1.6-AII |

| Rated evaporation capacity (t/h) | 0.5 | 1 | 2 | 4 |

| Working pressure(Mpa) | 0.7/1.0 | 0.7/1.0/1.25 | 0.7/1.0/1.25/1.6 | 1.25/1.6 |

| Rated steam temperature(℃) | 170/184 | 170/184/194 | 170/184/194/204 | 194/204 |

| Feed water temperature(℃) | 20 | 20 | 20 | 20 |

| Effective area of grate(m2) | 1.28 | 2.1 | 3.36 | 5.2 |

| Fuel consumption (Kg/h) | 76 | 150 | 301 | 602 |

| Exhaust flue gas temperature(C) | 165 | 165 | 165 | 165 |

| Thermal Efficiency (%) | 80 | 80 | 80 | 80 |

| Size(m) | 3.2x 2.0x 2.6 | 4.1x 2.2x 2.9 | 4.7x 2.3x 3.2 | 5.6x 2.5x 3.5 |

| Weight (t) | 8 | 12 | 15 | 22 |

Chemical industry, textile plant, rice mill, garment factory, livestock, farm, hotel, school, etc.

Biomass Fuel Materials

1. Rice husk 2. Straw

3. Wood Chips 4. Peanut Shells

5. Coconut Shells 6. Palm Shells

7. Bagasse 8. Biomass Pellet

Warranty and after-sale service

Gentle Boiler promises the top quality of every set of machine and best after-sales service as followings :

(A) The boiler body guarantee is two years, for accessories three years

(B) During the guarantee period , if the main body defective or broken without wrong operating , Gentle Boiler must replace the parts for free or prepare the spare-parts for free.

(C) Gentle Boiler should provide boiler technical service and operation guidance for whole life

long.

(D) Regarding to the installation and training , the buyer should take all the correlative charges (accommodation and food , round -trip tickets)

Q1: How can you get the best price quickly?

(1)We need to know the boiler capacity, the fuel you plan to use

and the steam pressure you need, and then we can confirm the boiler

model.

(2) Customer needs to provide us your name, email address and company name, and then we will send you price list immediately.And if you use whatsapp, skype or wechat, you can provide us your ID, it will be more convenient for our communication.

Q2: Why should you believe our boiler quality?

(1).Strength calculation report with applied materials information;

(2).100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

(3).100% X-ray inspection(welding seam): ensure the quality of entire boiler;

(4).Hydrostatic test: ensure the standard working pressure and safety;

(5).Passed SGS certificate.

Q3: What about the installation and Commissioning?

After you receive the boiler, we will guide you to make some

preparation for installation;If necessary, our expert will fly to

your local place in 72 hours. The experts will responsible for

guiding installation and commissioning. But the buyer will be in

charge of fee corresponding.

Q4:What is the using life of your boiler?

A:Normally the boiler is designed for 20 years life span, but with

right operation and good maintenance,the boiler can be used for

20-25 years.

Q5:Whether the boiler can burn dual fuel or multi-fuel?

boiler have oil burner, gas burner, and oil&gas dual fuel

burner, we can offer the specific burner based on customers’

requirement.