Henan Jinzhen Boiler Co., Ltd. |

|

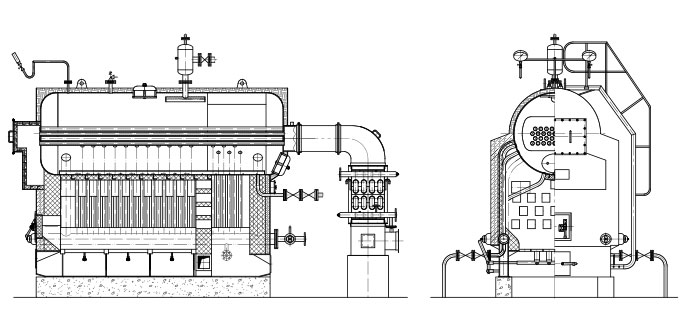

DZH type wood fired steam boiler is a horizontal three-return water-fire tube type boiler. A row of water-cooled wall tubes are arranged on the left and right sides of the furnace, and two sets of tube bundles are arranged in the drum to form two return paths. The boiler has sufficient heating surface and is equipped with a tail heating surface economizer. It is equipped with drums and induced draft fans for mechanical ventilation. Layered combustion.

This biomass steam boiler has high automation level, automatic adjustment of boiler feed water, high and low water level alarm, low water level interlock protection, and interlocking protection of lead and blower. Auxiliary auxiliary equipment is complete.

Structure

Bolier Advantage

Classical Structure

Advanced Structure: DZH boiler adopting threaded fire tubes, single water drum, horizontal shell type boiler with 3 fire-passes structure, water-tube fire-tube mix design. Comparing with DZL series boiler, DZH series boiler has better adaptability on fuels, it can fire coal, rice husk, nut shell, sawdust, waste wood pieces, also can fire wood logs, straws. But, coal fired steam boiler can only support manual fuel feeding, and manual ash remove.

High Quality Control

High Quality Control: In manufacturing processes, we has adopting steel strength test, automatic steel cutting/ plate rolling/ welding, 100% x-ray welding check, magnetic particle check c-scan ultrasonography Ultrasound check, fluorescent penetrating check, hydraulic (water) pressure test, boiler thermal efficiency test,etc, to make sure all finished products is qualified.

Low Fuel & Labor Cost

Biomass steam boiler can firecoal, rice husk, nut shell, sawdust, waste wood pieces, also can fire wood logs, straws. This will markedly reduce user’s fuel consumption cost, increase company’s benefits. Only need 1 worker to operate the fuel feeding and slag removing.

| Model Item | DZH0.5-0.7-AII DZH0.5-1.0-AII | DZH1-0.7-AII DZH1-1.0-AII DZH1-1.25-AII | DZH2-0.7-AII DZH2-1.0-AII DZH2-1.25-AII DZH2-1.6-AII | DZH4-1.25-AII DZH4-1.6-AII |

| Rated evaporation capacity (t/h) | 0.5 | 1 | 2 | 4 |

| Working pressure(Mpa) | 0.7/1.0 | 0.7/1.0/1.25 | 0.7/1.0/1.25/1.6 | 1.25/1.6 |

| Rated steam temperature(℃) | 170/184 | 170/184/194 | 170/184/194/204 | 194/204 |

| Feed water temperature(℃) | 20 | 20 | 20 | 20 |

| Effective area of grate(m2) | 1.28 | 2.1 | 3.36 | 5.2 |

| Fuel consumption (Kg/h) | 76 | 150 | 301 | 602 |

| Exhaust flue gas temperature(C) | 165 | 165 | 165 | 165 |

| Thermal Efficiency (%) | 80 | 80 | 80 | 80 |

| Size(m) | 3.2x 2.0x 2.6 | 4.1x 2.2x 2.9 | 4.7x 2.3x 3.2 | 5.6x 2.5x 3.5 |

| Weight (t) | 8 | 12 | 15 | 22 |

Boiler Picture

Application for biomass steam boiler

Wood fired steam boiler is suitable for painting room, drying box, drying tower painting line and other purposes.It is especially suitable for central heating in urban residential areas, industrial production, enterprises and institutions, schools, hotels, bath centers and other places where heating, hot water and steam are needed.

After-sales Services:

1. Assist clients to prepare for the first construction, and also

can arrange engineer on-site instruction of installation and

commissioning

2. Install and debug the equipment;

3. Train the first-line operators, application of theoretical

learning + product cognitive learning + examination + practical

repeated operation learning + phased procuratorial learning effect

Factory assurance:

1. One year quality assurance system;

2. Provide professional and high-quality parts according to the

factory price;

3. It can be designed and produced according to the user's voltage

frequency;

4. 100% tested before delivery;

5. Skid-mounted complete system available 180-- 3000 kw;

6. Complete system fixed on Skid rack available 180-- 3000 kw;

7. Engineer on-site instruction of installation and commissioning

available, and remote guidance and video services.