oepoch industrial technology |

|

Variable displacement axial piston pump-type V60N

Variable displacement axial piston pump-type V60N

Overview

Variable displacement axial piston pumps operate according to the bent axis principle. They adjust the geometric delivery volume from maximum to zero. As a result they vary the volumetric flow that is provided to the loads.

The axial piston pump type V60N is designed for open circuits in mobile hydraulics and works according to the swash plate principle. It is available with the option of a thru-shaft for operating additional hydraulic pumps in series.

The pump is fitted above all to the power take-off on commercial vehicle transmissions. The range of pump controllers allows the axial piston pump to be used in a variety of applications.

Features and benefits:

Intended applications:

Basic version

Nominal size

| Coding | Geometric displacement (cm3/rev) | Nominal pressure Pnom (bar) | Peak pressure Pmax (bar) |

| 060 | 60 | 350 | 400 |

| 090 | 90 | 350 | 400 |

| 110 | 110 | 350 | 400 |

| 130 | 130 | 400 | 450 |

Rotating directions

| Coding | Description |

| L | Anti-clockwise |

| R | Clockwise |

When looking at the shaft journal

Shaft versions

| Coding | Description | Designation/Standard | Max. drive torque (Nm) |

| D | Parallel key spLined shaft | Similar to DIN ISO 14 (trucks) | 800 |

| M | Spline shaft | DIN 5480 (only V60N-090, V60N-110) | 530 |

| H | Spline shaft | SAE-B J 744 13T 16/32 DP 22-4 ISO 3019-1 (only V60N-060) | 210 |

| U | Spline shaft | SAE-B J 744 short 13T 16/32 DP 22-4 ISO 3019-1 short (only V60N-060) | 210 |

| T | Spline shaft | SAE-BB J 744 15T 16/32 DP 25-4 ISO 3019-1 (only V60N-060) | 340 |

| S | Spline shaft | SAE-C J 744 14T 12/24 DP 32-4 ISO 3019-1 | 640 |

| Q | Spline shaft | SAE-CS 21T 16/32 DP 35-4 ISO 3019-1 (only V60N-090, V60N-110, V60N-130) | 900 |

Flange versions (input side)

| Coding | Description | Designation |

| Y | Flange | ISO 7653-1985 (for trucks) |

| P | Flange | ISO 7653-1985 10° rotated (for trucks)(only V60N-110, V60N-130) 1) |

| X | Flange | SAE-B 2-hole J 744 - 45° rotated 101-2 ISO 3019-1 (only V60N-060) |

| Z | Flange | SAE-B 4-hole J 744 101-4 ISO 3019-1 (only V60N-060) |

| F | Flange | SAE-C 4-hole J 744 127-4 ISO 3019-1 |

| G | Flange | 125 B4 HW ISO 3019-2(only V60N-090) |

Seals

| Coding | Description | |

| N | NBR | |

| V | FKM | |

Housing versions

| Coding | Description |

| 1 | Suction and pressure port axial |

| 2 | Suction and pressure port radial, with thru-shaft |

| 3 | Suction and pressure port radial |

| 4 | Suction and pressure port axial, ports SAE J 518 (only V60N-090) |

Additional functions

| Coding | Description |

| 0 | None |

Controllers

| Coding | Description | |||

| LSNR | Load-sensing controller with integrated pressure limitation. The LSNR controller is a delivery flow controller that generates a variable volumetric flow independently of the rotation speed. It sets a constant difference between the load pressure and pump pressure by continuously adapting the geometric displacement of the pump to the quantity required for the consumers. The integrated pressure limitation restricts the maximum pressure to a set value. Coding LSN: Discontinued unit; see | |||

| LSNRT | Load-sensing controller with forced LS relief and integrated pressure limitation. As well as the LSNR controller, the LSNRT contains internal LS signal relief. It is suited to hydraulic systems whose LS relief does not take place in proportional directional spool valves. Internal leakage current Ò 1.5 lpm | |||

| NR | Pressure controller, adjustable directly at the pump. The pressure controller maintains a constant system pressure independently of the required delivery flow. It is suited to constant pressure systems where differing delivery flows are required or for efficient pressure limitation of a hydraulic system. Coding N: Discontinued unit | |||

| NXR | Remote-controlled pressure controller. The pressure is set using an externally piped pressure-limiting valve (not included in the scope of delivery). | |||

| QNR/... | Flow controller with integrated pressure limitation for setting a constant flow rate independently of the speed. The quantity controller generates a constant differential pressure via an orifice in the P channel. The differential pressure can be adjusted between 20 and 55 bar; the orifice is available in various gradings. This allows flexible adjustment of the volumetric flow. | |||

| Orifice (mm) | Volumetric flow at 20 bar differential | Orifice (mm) | Volumetric flow at 20 bar differential | |

| pressure (lpm) | pressure (lpm) | |||

| 3 | approx. 23 | 7 | approx. 127 | |

| 3.5 | approx. 32 | 7.5 | approx. 146 | |

| 4 | approx. 42 | 8 | approx. 166 | |

| 4.5 | approx. 53 | 8.5 | approx. 188 | |

| 5 | approx. 65 | 9 | approx. 210 | |

| 5.5 | approx. 65 | 9.5 | approx. 234 | |

| 6 | approx. 94 | 10 | approx. 260 | |

| 6.5 | approx. 110 | |||

| Coding | Description |

| PR | Electric proportional pressure controller with increasing characteristic curve. The maximum pressure and minimum pressure can be adjusted mechanically; in between these values, electrical adjustment is possible. |

| P1R | Electric proportional pressure controller with decreasing characteristic curve. The controller is specifically developed for fan and generator drives. In the event of a power failure, the pump generates the maximum pressure. The maximum pressure and minimum pressure can be mechanically adjusted at the controller. |

| /V | Size 130: Electric proportional delivery flow controller with increasing characteristic curve. The V controller is an electrically actuated controller that sets an appropriate geometric displacement for the pump in accordance with a current value. Therefore, the pump generates a variable volumetric flow that is dependent on the rotation speed. For use in open centre systems with operating pressures of < 25 bar, an external supply pump or pump pre-load valve must be provided to ensure reliable adjustment. Only in combination with pressure control (codings NR or NXR) |

| /V1 | Size 130: Electric proportional delivery flow controller with decreasing characteristic curve. In comparison with the /V controller, the /V1 controller has a negative characteristic curve, i.e. in the event of power failure, the pump operates at a maximum geometric displacement. For use in open centre systems with operating pressures of < 25 bar, an external supply pump or pump pre-load valve must be provided to ensure reliable adjustment. Only in combination with pressure control (codings NR or NXR) |

Intermediate plates

Intermediate plate version, only in combination with one of the

controllers described above

| Coding | Description |

| /ZL | Size 060, 090, 110: Intermediate plate with power controller (torque limitation) Product “Pressure x Delivery flow” = constant Adjustment range: 25 ... 100% max. drive torque Codinq LLSN, LN: Discontinued units |

| /ZW | Angled intermediate plate (45°) mandatory for mounting controllers at pumps with housing version -2, -3 |

| /L | Adjustment range: 200 - 700 Nm Size 130: Power controller (standard) |

| /PR | Electric proportional pressure controller with increasing characteristic curve. The maximum pressure and minimum pressure can be adjusted mechanically; in between these values, electrical adjustment is possible. |

| /ZV | Size 060, 090, 110: Electric proportional delivery flow controller with increasing characteristic curve. For use in open centre systems with operating pressures of < 25 bar, an external supply pump or pump pre-load valve must be provided to ensure reliable adjustment. The ZV controller is designed as an intermediate plate. (It acts on the set piston from above and electrically adjusts the pivoting angle of the pump.) |

| /ZV1 | Size 060, 090, 110: Electric proportional delivery flow controller with decreasing characteristic curve. For use in open centre systems with operating pressures of < 25 bar, an external supply pump or pump pre-load valve must be provided to ensure reliable adjustment. The ZV1 controller is designed as an intermediate plate. (It acts on the set piston from above and electrically adjusts the pivoting angle of the pump.) |

Solenoid voltage and version

| Coding | Nominal voltage | Description | |

G 12 G 24 | 12 V DC 24 V DC | Version with connection DIN EN 301-803 With male connector | |

S 12 S 24 | 12 V DC 24 V DC | Version with bayonet connection (bayonet PA 6, SCHLEMMER, suitable for cone with bayonet 10 SL). The delivery does not include a male connector. |

Stroke limitation

| Coding | Description |

| No designation | No stroke limitation |

| 2 | With adjustable stroke limitation (for housing version 1 and 4: all sizes, for housing version 2 and 3: only V60N-090, V60N-130) |

| 2/... | Stroke limitation fixed with specification of the set geometric displacement Vg (cm3/rev.) |

Ports

| Coding | Ports |

| No designation | ISO 228/1 |

| UNF | SAE J 514 |

Order coding example:

V60N-110 RDYN-2-0-01/LSNR-350-A00/76- C 022

Flange versions (output side)

Table 13 Flange versions (output side)

| Coding V60N | Flange | Shaft | ||

| 060 | 090/110 | 130 | ||

| C 010 | -- | C 030 | ISO 7653-1985 | DIN ISO 14 |

| C 011 | C 021 | C 031 | SAE-A 2-hole J 744 82-2 ISO 3019-1 | SAE-A J 744 (16-4 ISO 3019-1) 9T 16/32 DP |

| C 012 | C 022 | C 032 | SAE-A 2-hole J 744 82-2 ISO 3019-1 | SAE-A J 744 (16-4 ISO 3019-1) 1) 9T 16/32 DP 1) |

| C 013 | -- | -- | SAE-A 2-hole J 744 82-2 ISO 3019-1 | 19-4 ISO 3019-1 11T 16/32 DP |

| C 014 | C 024 | C 034 | SAE-B 2-hole J 744 101-2 ISO 3019-1 | SAE-B J 744 (22-4 ISO 3019-1) 13T 16/32 DP |

| -- | -- | -- | SAE-B 2-hole J 744 101-2 ISO 3019-1 | SAE-BB J 744 (25-4 ISO 3019-1) 15T 12/24 DP |

| C 015 | C 025 | C 035 | SAE-B 4-hole J 744 101-4 ISO 3019-1 | SAE-B J 744 (22-4 ISO 3019-1) 13T 16/32 DP |

| -- | C 027 | C 037 | SAE-C 2-hole J 744 127-2 ISO 3019-1 | SAE-C J 744 (32-4 ISO 3019-1) 14T 12/24 DP |

| -- | C 028 | C 038 | SAE-C 4-hole J 744 127-4 ISO 3019-1 | SAE-C J 744 (32-4 ISO 3019-1) 14T 12/24 DP |

Note

Pay attention to the maximum permissible drive torque, as the flange or shaft may be damaged otherwise.

An additional support is to be provided for pump combinations.

Other versions on request.

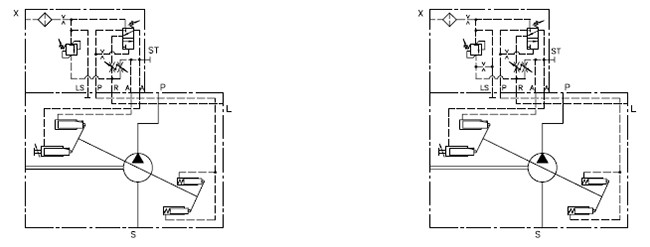

Controller switching symbols

Coding LSNR Coding LSNRT

Coding QNR

Coding NR Coding NXR

1 External pressure-limiting valve

(not included in scope of delivery)

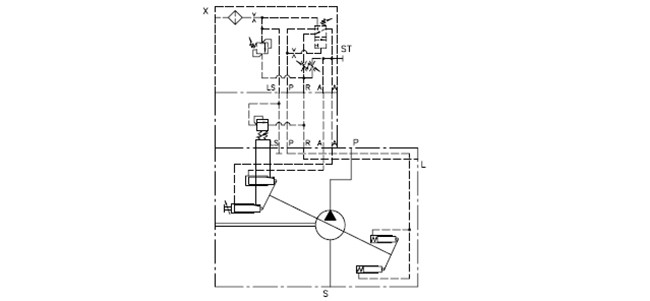

Coding PR Coding P1R

Types V60N-060, V60N-090, V60N-110

Coding .../ZL

Coding .../ZV Coding .../ZV1

1 External supply pump with pressure-limiting valve 1 External supply pump with pressure-limiting valve

and check valve (not included in scope of delivery) and check valve (not included in scope of delivery)

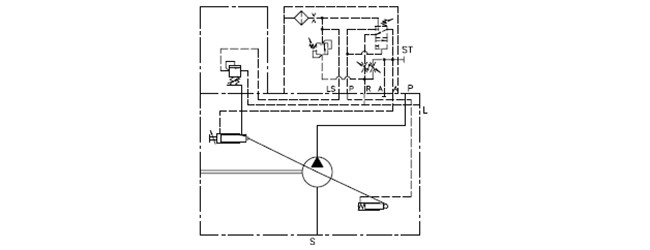

Type V60N-130

Coding .../L

Coding .../V Coding .../V1

1 External supply pump with pressure-limiting valve 1 External supply pump with pressure-limiting valve

and check valve (not included in scope of delivery) and check valve (not included in scope of delivery)

Parameters

| Description | Variable displacement axial piston pump |

| Design | Axial piston pump according to the swash plate principle |

| Mounting | Power take-off on commercial vehicle gearboxes (flange ISO 7653-1985 for trucks) or flange mounting |

| Surface | Primed |

| Drive/output torque | See under "Additional parameters" |

| Installation position | Any |

| Rotating direction | Clockwise or anti-clockwise |

| Change of rotating direction | V60N-060...-110: Turn the end plate of the pump (see dimension diagram) and replace the port plate |

| Ports | Suction port Pressure port Drain port Pressure gauge connection |

| Hydraulic fluid | Hydraulic oil: according to DIN 51 524 Part 1 to 3; ISO VG 10 to 68 according to DIN 51 519 Viscosity range: min. approx. 10; max. approx. 1000 mm 2/s Optimal operating range: 16 to 35 mm2/s Also suitable for biologically degradable pressure fluids type HEPG (polyalkalene glycol) and HEES (synthetic ester) at operating temperatures up to approx. +70°C. |

| Purity class | 19/17/14, ISO 4406 |

| Temperatures | Ambient: approx. -40 to +60°C, oil: -25 to +80°C, pay attention to the viscosity range! Start temperature: down to -40°C is permissible (observe start-viscosity!), as long as the steady-state temperature is at least 20K higher for subsequent operation. Biologically degradable pressure fluids: note manufacturer specifications. With consideration for the seal compatibility, not above +70°C. |

Additional parameters

| Description | Nominal size | |||

| 060 | 090 | 110 | 130 | |

| Max. swash plate angle | 20.5° | 21.5° | 21.5° | 21.5° |

| Absolute inlet pressure required in open circuit | 0.85 bar | 0.85 bar | 0.85 bar | 0.85 bar |

| Max. permissible housing pressure (static/dynamic) | 2 bar/3 bar | 2 bar/3 bar | 2 bar/3 bar | 2 bar/3 bar |

| Max. permissible inlet pressure (static/dynamic) | 20 bar/30 bar | 20 bar/30 bar | 20 bar/30 bar | 20 bar/30 bar |

| Max. rotation speed during suction operation and max. swash plate angle at 1 bar abs. Inlet pressure | 2500 rpm | 2300 rpm | 2200 rpm | 2100 rpm |

| Max. rotation speed with zero stroke and 1 bar abs. Inlet pressure | 3000 rpm | 3000 rpm | 3000 rpm | 3000 rpm |

| Min. rotaion speed in continuous operation | 500 rpm | 500 rpm | 500 rpm | 500 rpm |

| Required drive torque at 100 bar | 100 Nm | 151 Nm | 184 Nm | 230 Nm |

| Drive power at 250 bar and 2000 rpm | 53 kW | 79.5 kW | 97.2 kW | 120 kW |

| Weight torque | 30 Nm | 35.5 Nm | 40 Nm | 40 Nm |

| Inertia torque | 0.005 kg m2 | 0.008 kg m2 | 0.01 kg m2 | 0.011 kg m2 |

Noise level at 250 bar, 1500 rpm and max. swash plate angle(measured in acoustic measurement chamber according to DIN ISO 4412, measurement distance 1 m)

| 75 dB(A) | 75 dB(A) | 75 dB(A) | 75 dB(A) |

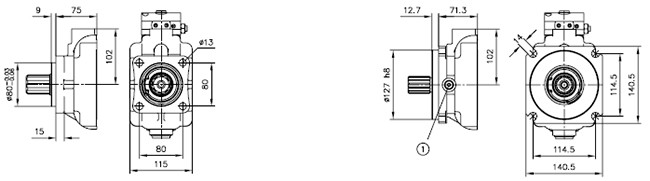

Dimensions(All dimensions in mm, subject to change!)

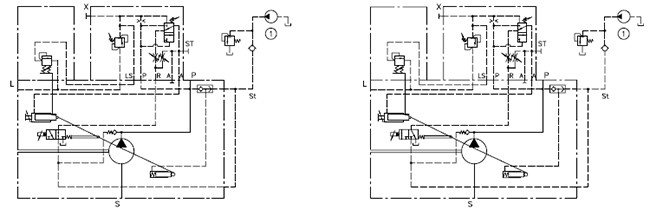

1. Basic pump

Rotating direction clockwise (viewed from shaft journal) Rotating direction anti-clockwise (viewed from shaft journal)

1 Shaft version

2 Flange version

3 Housing version

4 Controller and intermediate plates according

5 Delivery includes attachment kit for suction intakes

| Flange version | Housing version | A | B |

| Y | -1 | 253.5 | 100.0 |

| F, Z, X | -1 | 249.8 | 96.3 |

| Y | -2,-3 | 292.0 | 100.0 |

| F, Z, X | -2,-3 | 288.3 | 96.3 |

Ports P, S and D (ISO 228/1 (BSPP))

| P | Pressure port G 3/4 |

| S | Flange suction port |

| D | Drain port G 3/4 |

| X | G 1/4 |

For coding UNF, ports SAE J 514

| P | Pressure port 1/16-12 UN-2B |

| S | Flange suction port |

| D | Drain port 1 1/16-12 UN-2B |

| X | G 1/4 (ISO 228/1 (BSPP)) with adapter for 7/16-20 (SAE-4) |

Stroke limitation

1 Stroke limitation (Vg approx. 4 cm3/rev.)

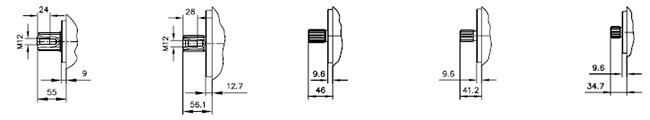

Shaft versions

Shaft versions

Parallel key splined Spline shaft Spline shaft Spline shaft Spline shaft

shaft Coding S Coding T Coding H Coding U

Coding D (SAE-C 14T (SAE-B-B 15T (SAE-B 13T (SAE-B 13T

(similar to DIN ISO 14) 12/24DP) 16/32DP) 16/32DP) 16/32DP short)

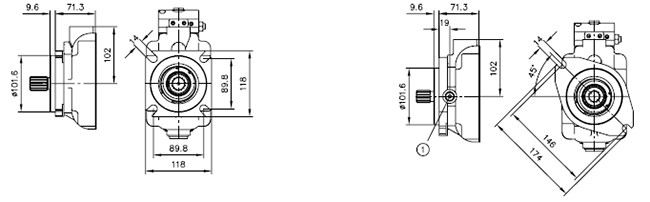

Flange versions

Coding Y Coding F

(ISO 7653-1985) (SAE-C 4-hole)

(127-4 ISO 3019-1)

1 Bleeding G 1/8

Coding Z Coding X

(SAE-B 4-hole) (SAE-B 2-hole)

(101-4 ISO 3019-1) (101-2 ISO 3019-1)

1 Bleeding G 1/8

Housing version -1 (axial ports)

1 Delivery includes attachment kit for suction intakes

Housing version -2 (radial ports, with thru-shaft)

1 Flange version (output side)

| Rotating direction clockwise | Rotating direction anti-clockwise |

| A = suction port | A = pressure port |

| B = pressure port | B = suction port |

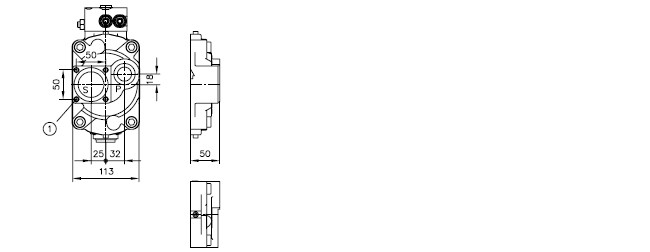

Flange version (output side)

Coding C 010 Coding C 011, C 012

(ISO 7653-1985) (SAE-A 2-Hole)

Coding C 014 Coding C 015

(SAE-B 2-hole) (SAE-B 4-hole)

1 Support 8xM8

Housing version -3 (radial ports)

| Rotating direction clockwise | Rotating direction anti-clockwise |

| A = suction port | A = pressure port |

| B = pressure port | B = suction port |

If you are interested in this product, please contact us for the parameters of Type V60N-090, Type V60N-110, Type V60N-130 and more information.