oepoch industrial technology |

|

4/2 and 4/3 way isolator valve-Type Z4WEH/Z4WH22 ..L5X

Features:

– Directional spool valve, pilot operated

– 2 types of actuation

Electrohydraulic (type WEH)

Hydraulic (type WH)

– Function as shut-off through valve or shut-off/through

valve/short-circuit valve

– Free flow in P and T in every spool position

– Porting pattern to ISO4401-08-08-0-05

– Wet-pin DC or AC voltage solenoids, optional

– Manual override, optional

Function and configuration

Valves of type Z4WEH are directional spool valves with

electrohydraulic actuation. They control the start and stop of a

flow.

These directional valves basically consist of the main valve with

housing (1), main control spool (2), one or two return springs (3.1

and 3.2), as well as pilot valve (4).

Main control spool (2) in the main valve is held by springs or

through pressurization in the zero or initial position. In the

initial position, the two spring chambers (6) and (7) are connected

pressure less to tank via pilot channel (4). The pilot valve is

supplied with pilot oil via pilot line (11). The supply can be

provided internally or externally (externally via port X in the

sandwich plate).

When the pilot valve is operated, e.g. solenoid "a", the pilot

spool (not shown on the drawing) is pushed to the left and spring

chamber (7) is consequently pressurized to pilot pressure. Spring

chamber (6) remains pressure less.

The pilot pressure acts on the left side of main control spool (2)

and pushes it against spring (3.1). In the main valve the ports are

connected on the component side and on the plate side depending on

the symbol.

When the solenoid is de-energized, the pilot spool returns to its

initial position. Spring chamber (7) is unloaded to tank.

The pilot oil is drained internally from spring chamber (7) via

pilot valve (4) into channel T (Y).

An optional manual override (5) allows the pilot spool to be moved

without energization of the solenoid.

Throttle insert

The use of throttle insert (10) is required, if the pilot oil

supply in channel P of the pilot valve is to be limited.

Throttle insert (10) is to be installed in channel P of the pilot

valve.

1= component side

2 = plate side

Pilot oil supply

External: 8 closed Internal: 8 open

9 open 9 closed

Pilot oil port "X" only possible with Z4WEH 22 ... .

Spool symbols

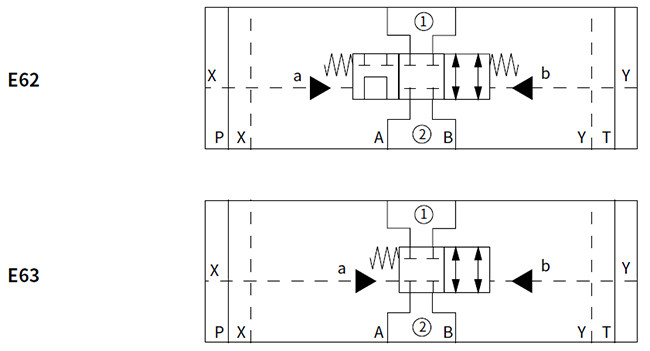

Type Z4WEH ( ① = component side, ② = plate side)

Ordering code

Version "ET"

Version "T"

Type Z4WH ( ① = component side, ② = plate side)

Ordering code

Version "No code"

Specification

Technical data

| Fixing position | Optional | ||

| Environment temperature range | ℃ | -30 to +50 (NBR seal) | |

| -20 to +50 (FKM seal) | |||

| Weight | Single solenoid | kg | 20.8 |

| Double solenoids | kg | 21.1 | |

| Valve with hydraulic actuation | kg | 20 | |

| Switching time adjustment | kg | 0.8 | |

| Pressure reducing valve | kg | 0.4 | |

| Plate for version “T” | kg | 0.5 | |

| Max.operating pressure | Port A, B, X, Y | bar | 315 |

| Port T | bar | 160 (version “WEH” with AC solenoid) | |

| 315 (version “WH”) | |||

| 210 (version “WEH” with DC solenoid) | |||

| Port P | bar | 315 | |

| External pilot oil supply | |||

| Internal pilot oil supply | bar | 210 (without pressure reducing valve) | |

| 315 (with pressure reducing valve) | |||

| Max. flow-rate | L/min | 650 | |

| Fluid | Mineral oil suitable for NBR and FKM seal | ||

| Phosphate ester for FKM seal | |||

| Fluid temperature range | ℃ | -30 to +80 (NBR seal) | |

| -20 to +80 (FKM seal) | |||

| Viscosity range | mm2/s | 10 to 500 | |

| Minimum pilot pressure | bar | 12 | |

| Maximum pilot pressure | bar | 250 | |

| Cleanliness class to ISO code | Maximum permissible degree of contamination of the pressure fluid is to ISO 4406 (C) class 20/18/15 | ||

Caution: with electrical connections the protective conductor (PE) must be

connected according to the relevant regulations.

Unit dimensions (dimensions in mm)

Type Z4WEH22

Type Z4WEH22

1 Nameplate of complete valve

2 Nameplate of pilot valve

3 Main valve

4 Port X (G1/4) for external pilot control

5 Pressure reducing valve "D3" (must be used in the case of pilot

pressures above 210 bar; only with version "Z4WEH")

6 Switching time adjustment (for throttle check valve);

Depending on the installation position, meter-in or meter-out

control (illustration: meter-in control)

7 R-ring plate

8 Pilot valve

– Type 4WE 6 J.. for symbol E62

– Type 4WE 6 Y.. for symbol E63

9 Solenoids "a" and "b" (can be rotated 90°)

10 Dimension for valve with manual override "N"; dimensions () for

valve with AC solenoid

11 Identical seal rings for ports A, B, P, T (main valve)

12 Identical seal rings for ports A, B, P, T

13 Pilot oil subplate

14 Space required to remove mating connector

15 Locating pin

16 Valve mounting bores

Valve mounting screws (separate order)

6 hexagon socket head cap screws

ISO 4762 - M10 - 10.9

Stroke adjustment, attachment options (dimensions in mm)

17 Locknut

24 A/F

18

Adjustment spindle, hexagon socket 6 A/F

The stroke adjustment feature limits the stroke of the main spool.

The spool stroke can be reduced by loosening locknut (19) and

turning adjustment spindle (20) clockwise. The control chamber must

be pressure less during this process.

Stroke 9.5 mm (1 turn = 1.5 mm stroke)

Attachment | Ordering | L1 | L2 |

Stroke adjustment | 10 | 94 | 248 |

Stroke adjustment | 11 | 94 | |

Stroke adjustment | 12 | 248 |