oepoch industrial technology |

|

RV series V ball valve

It is a kind of advanced control valve with right angle rotation. It is mainly used as a regulating valve or as an on-off valve. The v-type spool is designed with a special shape of the v-notch, so it has a large shearing force and self-cleaning function, especially suitable for the control of media containing fibers or tiny solid particles. Therefore, this product is widely used in the chemical, biochemical, petroleum, polysilicon, chemical fiber, pharmaceutical, environmental, paper and other industrial sectors of the automatic control system.

Design feature

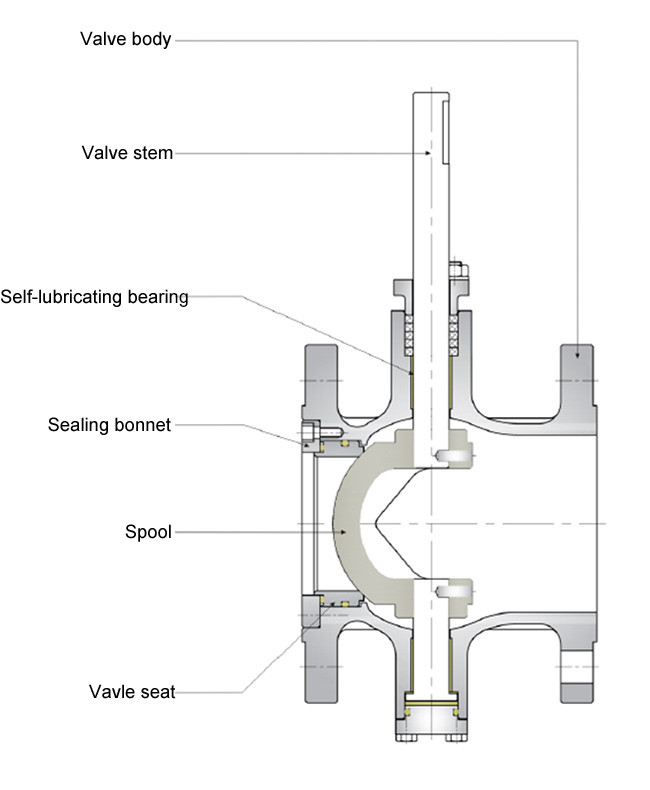

Valve body

The valve body is designed in one piece to avoid leakage that may occur in the middle flange connection.

Valve stem

The outer circle is made of coreless grinding, and the friction coefficient between the filler and the packing is small. The valve stem and the valve core are splined, which has good neutrality and large bearing torque. The spline connection effectively eliminates the matching clearance between the valve stem and the valve core, and improves the adjustment precision of the valve.

Self-lubricating bearing

The upper and lower valve stems are fixed by self-lubricating bearings, which have high rotation precision and good rotation stability. Make the valve run smoother.

Sealing bonnet

The side-mounted sealing bonnet design makes valve maintenance more convenient.

Spool

Designed with a V-shaped notch with a special shape, the valve has an approximately equal percentage of flow characteristics. At the same time, the shear force and friction between the valve core and the sealing seat will be great during the movement, especially suitable for applications where the medium is viscous, fiber and solid particles are included. A small flow spool and noise reduction spool are also available.

Vavle seat

The wave spring is pre-tightened, so that the sealing seat is always in close contact with the valve core, and the sealing performance is good, which can automatically compensate the wear of the seal in long-term use.

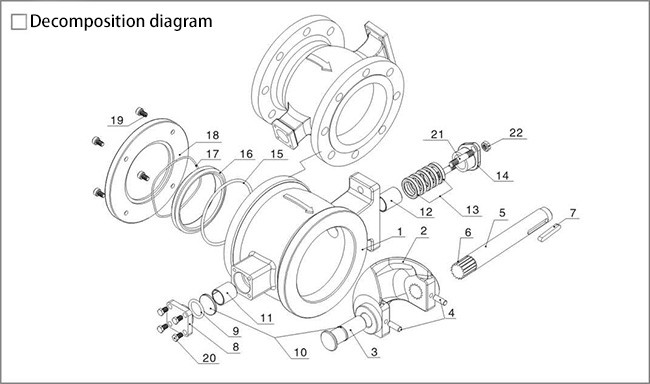

Parts List

| Nunber | Name | Quantity(Piece) | Material |

| 1 | Valve body | 1 | WCB,CF8,CF8M |

| 2 | Spool | 1 | CF8,CF8M+Hard chromium plating or spray welding Stelle |

| 3 | Rear stem | 1 | 17-4PH SS316 |

| 4 | Cylindrical pin | 2 | SS304,SS316 |

| 5 | Front stem | 1 | 17-4PH, SS316 |

| 6 | Spline | 1 | 17-4PH ,SS316 |

| 7 | Flat key | 1 | SS304,45# |

| 8 | Rear gland | 1 | CF8,CF8M |

| 9 | O-ring | 1 | Fluororubber |

| 10 | Adjustment mats | 1 | PTFE |

| 11 | Self-lubricating bearing | 1 | Composite material |

| 12 | Self-lubricating bearing | 1 | Composite material |

| 13 | Packing | A group | PTFE |

| 14 | Packing gland | 1 | CF8 |

| 15 | O-ring | 1 | Fluororubber |

| 16 | Seal seat | 1 | SS304,SS316+Hard chromium plating or spray welding Stelle |

| 17 | Wave spring | 1 | 17-4PH ,X-750 |

| 18 | Seal seat cover | 1 | Q235,SS304,SS316 |

| 19 | Socket head cap screws | 4 | SS304 |

| 20 | Hexagon screw | 4 | SS304 |

| 21 | Double head screw | 2 | SS304 |

| 22 | Hex nuts | 2 | SS304 |

Technical Parameters

Nominal diameter

Clip type DN:20,25,32,40,50,65,80,100,125,150,200,250.

Flange type DN:20,25,32,40,50,65,80,100,125,150,200,250,300,400,450,500,600,700.

Nominal pressure (PN): 1.0,1.6,2.5,4.0,6.4(Mpa)ASME150,300LB.

Temperature range: -40~120 (normal temperature); -40~230 (medium temperature); -40~425 (high temperature)

Structural length standard:The clip type is according to the manufacturer's standard.

Flange type according to ISA S75.04 and IEC/DIN 534-3-2 standards.

Pressure test:The shell test pressure is 1.5 times the nominal pressure. The seal test is 1.1 times the nominal pressure. The test medium is water.

Leakage: Metal-sealed seat media tested in the direction of the arrow to meet Class F of the ISO5208 seal rating, equivalent to the ANSI/FCI0.2IV x 1/100 standard. See the table below for details.

Maximum allowable leakage

| DN(mm) | Metal seat | Soft seat |

| 25 | 1.5ml/min | 0.15ml/min |

| 32 | 1.9ml/min | 0.19ml/min |

| 40 | 2.4ml/min | 0.24ml/min |

| 50 | 3.0ml/min | 0.30ml/min |

| 65 | 3.9ml/min | 0.39ml/min |

| 80 | 4.8ml/min | 0.48ml/min |

| 100 | 6.0ml/min | 0.60ml/min |

| 125 | 7.5ml/min | 0.75ml/min |

| 150 | 9.0ml/min | 0.90ml/min |

| 200 | 12.0ml/min | 1.20ml/min |

| 250 | 15.0ml/min | 1.50ml/min |

| 300 | 18.0ml/min | 1.80ml/min |

| 350 | 21.0ml/min | 2.10ml/min |

| 400 | 24.0ml/min | 2.40ml/min |

| 450 | 27.0ml/min | 2.70ml/min |

| 500 | 30.0ml/min | 3.00ml/min |

| 600 | 36.0ml/min | 3.60ml/min |

| 700 | 42.0ml/min | 4.20ml/min |

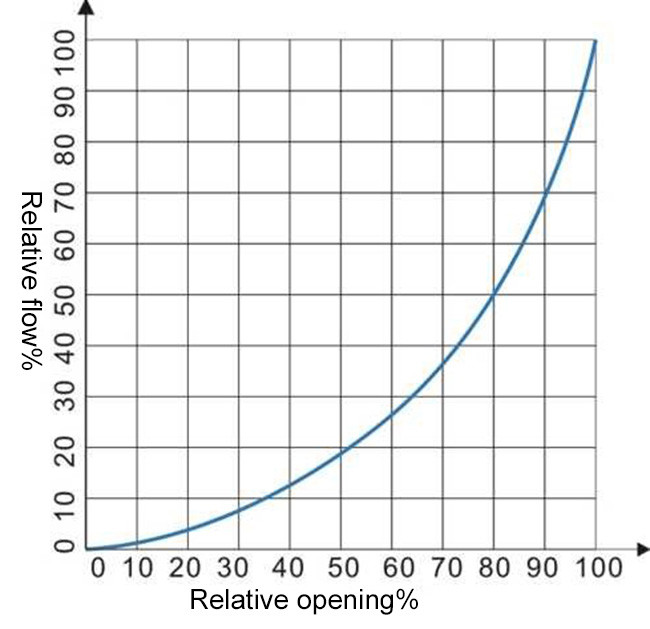

The inherent flow characteristics of the V-type regulator are equal percentage characteristics as shown.

Valve rated CV value

| Nominal diameter | Rated CV | Nominal diameter | Rated CV |

| DN25 | 27 | DN200 | 1860 |

| DN32 | 47 | DN250 | 2900 |

| DN40 | 70 | DN300 | 4320 |

| DN50 | 135 | DN350 | 6640 |

| DN65 | 210 | DN400 | 8000 |

| DN80 | 390 | DN450 | 10000 |

| DN100 | 560 | DN500 | 12200 |

| DN125 | 790 | DN600 | 17270 |

| DN150 | 1130 | DN700 | 25000 |

Valve maximum allowable differential pressure and torque

| DN(mm) | Clip type | Flange type | Torque (N,M) | |||

| Maximum closing pressure difference | Maximum control pressure difference | Maximum closing pressure difference | Maximum control pressure difference | |||

| (bar) | (bar) | (bar) | (bar) | 16(bar) | 40(bar) | |

| 25 | 50 | 35 | 40 | 35 | 25 | 48 |

| 32 | 50 | 35 | 40 | 35 | 25 | 55 |

| 40 | 50 | 35 | 40 | 35 | 30 | 60 |

| 50 | 50 | 35 | 40 | 35 | 35 | 70 |

| 65 | 50 | 35 | 40 | 35 | 60 | 140 |

| 80 | 50 | 35 | 40 | 35 | 80 | 224 |

| 100 | 40 | 25 | 40 | 25 | 140 | 315 |

| 125 | 40 | 25 | 40 | 25 | 160 | 480 |

| 150 | 40 | 25 | 40 | 25 | 220 | 930 |

| 200 | 35 | 25 | 40 | 25 | 350 | 1830 |

| 250 | 35 | 20 | 40 | 20 | 660 | 3125 |

| 300 | 40 | 20 | 1200 | 4000 | ||

| 350 | 40 | 20 | 1700 | 6120 | ||

| 400 | 40 | 20 | 2600 | 8030 | ||

| 450 | 40 | 20 | 3500 | 12000 | ||

| 500 | 30 | 10 | 3800 | 15000 | ||

| 600 | 30 | 10 | 6600 | 20500 | ||

Note: 1. The torque provided in the table is the torque at this pressure, which is based on the torque of the metal seat at normal temperature.

2. We recommend multiplying the safety factor by 1.3 times when selecting the actuator. The valve torque will vary with the medium and temperature.

Seat seal structure

Metal sealing seat Soft sealing seat High temperature metal sealing seat

| No. | Item | Temperature℃ | No. | Item | Temperature℃ | No. | Item | Temperature℃ |

| 1 | Seal seat cover | -40℃~160℃ -40℃~230℃

| 1 | Seal seat cover | -40℃~160℃

| 1 | Seal seat cover | -40℃~425℃

|

| 2 | Wave spring | 2 | Wave spring | 2 | Wave spring | |||

| 3 | O-ring | 3 | O-ring | 3 | Pressure ring | |||

| 4 | Vavle body | 4 | Vavle body | 4 | Seal ring | |||

| 5 | Seal seat | 5 | Seal seat | 5 | Seal seat | |||

| 6 | Spool | 6 | Seal ring | 6 | Vavle body | |||

| 7 | Spool | 7 | Spool |

Spool structure

Small flow spool

A wide range of small CV values are available for valves with a nominal diameter of 20 mm or 25 mm for precise control of small flows. It is ideal for control of some additives and coatings in the paper industry.

Noise reduction spool

In control valve applications, there are limits to the control valve noise in some cases. In practical applications, when some special sections use conventional valves, it is easy to exceed the standard, especially in gas and steam applications. Water and other liquids will cavitation in high pressure differential environments, damaging the piping system and will have a significant impact on valve life and accuracy. This spool can be used to solve it.

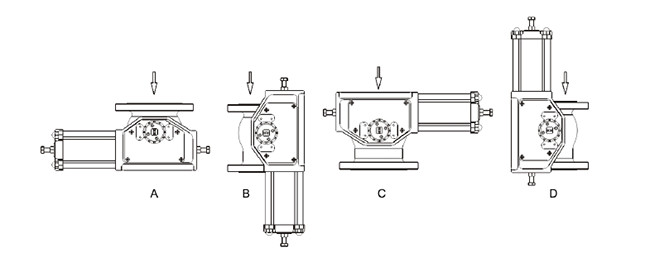

Actuator mounting orientation

Pneumatic V-type ball valve with Z series actuator standard factory direction as shown in Figure A. If there is an installation space limit, you can choose another three orientations.

Application

Pulp and fiber control in the paper industry

Slurry control in the biochemical industry

Powder and hard particle fluid control

Various flow control and pressure control