Qingdao Crowns Machinery Co., Ltd. |

|

Verified Suppliers

|

|

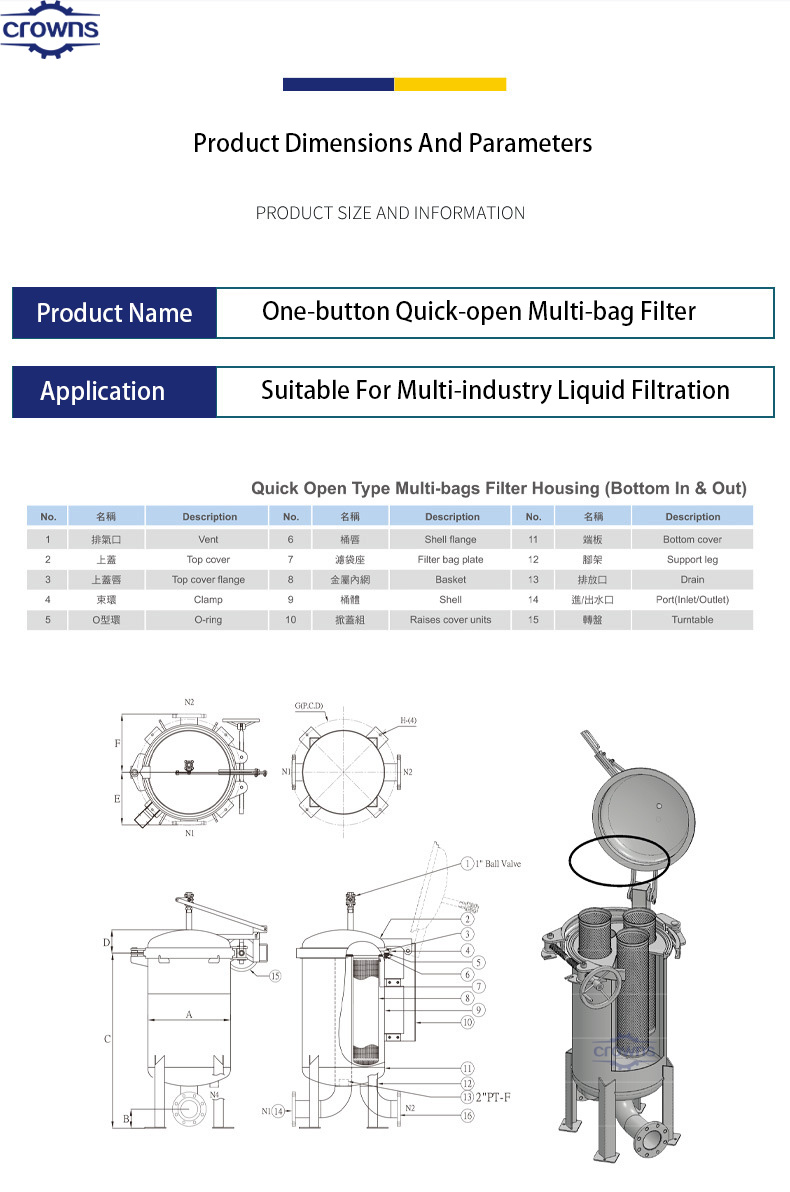

Stainless Steel Multi Bags Filter Housing Industrial Water Filters For Food Industry

![]()

Stainless steel multi bag filter housing is suitable for working conditions with a flow rate of 40~1000m3/h. It adopts side inlet and bottom outlet method (bottom inlet and bottom outlet method can also be used), and the filtered liquid medium is pressed in or pumped by the pressure in the pipeline Into the filter barrel, the liquid medium to be filtered is filtered by the filter bag supported by the filter basket supported by the electro-polishing punching hole, resulting in an ideal solid-liquid separation to achieve the effect of filtering the liquid medium. Lianhua multi bag filters can also be customized according to customer requirements.

Multiple housing styles available (standard, quick access, low profile, hinged)

Permanently piped housings are opened without tools and without disturbing the piping

Machined cover gasket groove provides positive O-ring sealing

Carbon steel, 304 or 316 stainless steel construction housings

Large-area, 30 inch deep, heavy-duty, 9/64 inch perforated baskets

Easy to clean

Low pressure drop

Four cover seal materials.

Pressure rating 150 psi

Flange connections for 2 through 12 inch pipe

Vent, drain and gate connections

![]()

![]()

![]()

![]()

Q1 : Where is your factory located?

A1 : Qingdao crowns machinery co.,ltd is located at Huangdao district ,Qingdao city, China

Q2 : Are you an integrated supplier for industrial filter machine ?

A2 : Yes, we can provide the complete solution line to customer

according to customer’s requirement.

Q3 : How about the quality control in your factory?

A3 : Qingdao crowns has the SOP (Standard Operation Procedure) and all the production

step must follow

up this SOP. Every machine needs at least automatic running over 72 hours and must be inspected carefully

before shipment.

Q4 : Will you offer the pre-sales service?

A4 : Yes, we have an experienced pre-sales team to support

customers not only including machine, technology

also water.

electrical,machine layout in factory, etc.

Q5 : What about the after-service? Will you send your engineer to

my country to help commission and install the

machine?

A5 : Surely, we have many experience technical engineers for

oversea service, they would help you install machine

and support training to workers also.

Q6 : What is the delivery time of the machine?

A6 : Actually, the delivery time of the machines is depended on the

machine options. Normally, the delivery

time of standard machine could be within 10-30 days

Q7 : What is the warranty of the machine ?

A7 : The whole machine’s warranty period is 12 months and key parts

will be depended.

Q8 : Do you provide any spare parts with machine?

A8 : Yes, CROWNS will provide one set standard spare parts to

customer according to different machines