Zhejiang TongJiang Holdings Company |

|

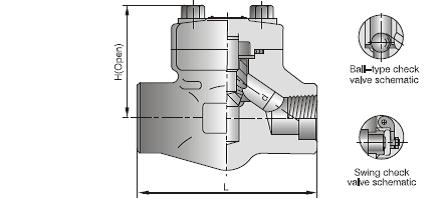

Non Return Check Valve in Forged A105 Threaded NPT of Horizontal Piston Type

Check Valve PRODUCT INTRODUCTION

Check Valve Description

Horizontal Piston Type Forged Steel Check Valve screwed features a Heavy Rugged Body with Bolted Cover Design Designed as per API 602, BS 5352, ASME B 16.34 available in End Connection of Socket Weld, Butt Weld and Threaded (Screwed) BSP or NPT having Pressure Ratings of Class 800# and 1500#.

TongJiang piston type horizontal lift type check valve incorporates self-cushioning effect. Body Guided piston assuring accurate return to seat ring to achieve leak tightness. TongJiang manufacturing range covers Regular Port and Standard Port both types of Forged Steel Check Valves.

Forged Steel Piston Lift Check Valve screwed are available in wide range of Body Material like ASTM A 105 – Forged Carbon Steel, ASTM A 182 F 304 / 304L / 316 / 316 L, Forged Stainless Steel 304, 304 L, 316, 316 L and ASTM A 182 F 11/22 – Alloy Steel to suit various industrial application. For High Pressure & Temperature application Stellited F6 Face Seat & Disc available.

| Design Standard | BS 5352 / API 602 / ASME B 16.34 |

| Inspection & Testing Standard | BS EN ISO 12266 – I (BS 6755 – I) / API 598 / ISO 5208 |

| Face To Face Distance | BS 5352 / API 602 / ANSI B 16.10 |

| End Connection | Screwed – Threaded End to ANSI B 1.20.1 |

| Socket Weld End to ANSI B 16.11 | |

| Butt Weld End to ANSI B 16.25 | |

| Manufacturing Size Range | 1/2″ (DN15) to 2″(DN 50) |

| Pressure Rating of Valve | 800# / 1500# |

| Body & Cover | ASTM A 105 – Forged Carbon Steel |

| 304 / 304L – ASTM A 182 F 304 / F 304L – Forged Stainless Steel | |

| 316 / 316L – ASTM A 182 F 316 / F 316L – Forged Stainless Steel | |

| ASTM A 182 F 11 / F 22 – Alloy Steel | |

| Disc & Seat | ASTM A 276 T – 304 / 316 (SS 304 / SS 316) |

| 304L / 316L (SS 304L / SS 316L) – ASTM A 276 T | |

| ASTM A 276 T – 410 (S.S. 410 – 13% Cr. Steel) | |

| ASTM A 182 GR F6A / Half – Full Stellited F6 | |

| Bolts / Stud & Nuts | ASTM A 193 GR. B7 / A 194 GR. 2H |

| S.S. 304/316/304L/316L |

A Compact But Extremely Sturdy Design for High Pressure & Temperature Service

Bolted Cover Design, easy to open cover

Piston Type Body Guide Disc

Assure Perfect Alignment of Disc & Seat Ring

Spring Loaded on request

Stelited F6 Disc & Seat optional

High Tesile B7/2H Fasteners

Power Plants & Process Industries

Petrochemical Plants & Refineries

Cement & Fertilizers Plants

Steel Plant

Process & General Industries

Sugar Industries & Distillery Plants

Water, Steam, Gas, Oil & other Non-aggressive media

Valve Outline Size Drawing

Class 800

| Specification | RP | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | ||

| (NPS) | F.P | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | |

| Face to face | L | Lft | 79 | 79 | 92 | 111 | 120 | 152 | 172 | 220 |

| (mm) | Swing | 79 | 79 | 92 | 111 | 120 | 120 | 140 | 178 | |

| Height | H | Lft | 61 | 61 | 61 | 78 | 84 | 84 | 118 | 132 |

| (mm) | Swing | 61 | 61 | 61 | 78 | 84 | 84 | 120 | 133 | |

| Flow port dimensions | d | Lift | 7 | 9 | 13 | 175 | 23 | 30 | 35 | 46 |

| (mm) | Swing | 8 | 105 | 135 | 18 | 24 | 29 | 36.5 | 45 | |

| Weight (Kg) | Lift | 1.2 | 1.5 | 17 | 3.3 | 4.2 | 4.2 | 10.5 | 12.5 | |

| Swing | 14 | 15 | 1.7 | 3.3 | 4.2 | 4.2 | 8.5 | 10.9 | ||

If you require other sizes and valve design standards, please send email to angela@tjfmcn.com to get the drawing.

Valve Packing with Plywood

Please feel free to contact with us at angela@tjfmcn.com or filling up an enquiry form instructed at the bottom.

You will get an effective response within 24 hours from TongJiang Team.

COMPANY PROFILE

floa

1. Our Factory

30 years experience of valve and pipeline industry.

10 senior technical engineers

20000 m2 production area

More than 100 employees to provide professional service.

As the reliable OEM for famous valve brand companies.

t ball valve

2. Factory Show

TONGJIANG Valve Technology Company was established for 30 years.

There are more than 100 employees which includes 10 professional engineers.

OUR SERVICE float ball valve

Reliable Quality, Competitive Price

Reply your inquiry in 2 hours with professional service.

Miss Angela

Mobile: +86 13588429004(Whatsapp)

Skype: angelazhuo1

E-mail: angela@tjfmcn.com

Tel No: +86 571 86991717

Official Website: www.zjtjvalve.com