Shenzhen Canroon Electrical Appliances Co., Ltd. |

|

Verified Suppliers

|

|

air cooling post weld heat treatment induction heating machine price

Brief introduction of air cooling post weld heat treatment induction heating machine price:

Brand: Canroon(China manufacturer)

Power:5kw, 10kw

Frequency:3-35kHZ

Heating temperature: can be high as 788℃

Voltage: 380-460V, 3 phase, 50/60HZ,

Suitable pipe size: 30-600mm diameter, less than 30mm thickness,

cooling system: air cooling

Application industries: offshore platform, power station, oil and gas pipeline construction, etc

Applications: PWHT/ post weld heat treatment, pipe welding preheat, joint anti-corrosion coating, etc

Features: small, portable, digital control, self-fault diagnosis, modular design, fault code feedback, etc

Application details of air cooling post weld heat treatment induction heating machine price:

suitable material:steel pipe, stainless steel pipe, with different size and thickness

suitable industry: offshore platform, power plant, oil and gas pipeline construction

Working site of post weld heat treatment of steel pipe using our induction heating machine with temperature recorder, small and portable,

Details of the working site: insulation blanket to keep heat, induction cable to create electromegnatic field, thermocouple to record the temperature of the corresponding position.

Temperature recorder can feedback the temperature and print PWHT curve for further research.

Technical parameters of air cooling post weld heat treatment induction heating machine price:

| Model | Temperature | Input Power | Input | Output | Dimension | Weight |

| CR2000-005B-12SF2 | 788℃ | 5kVA | 1-phase 220-240V 50-60Hz 20.8-22.7A | 4.2kW 5-60 KHz duty cycle 100% | W:242.9mm H:295.2mm D: 504.4mm

| 16kg

|

CR2000-005B-14TF1

| 788℃ | 5kVA | 3-phase 380-460V 50-60Hz 6.3-7.6A | 4.5kW 3-35 KHz duty cycle 100% | W:263mm H:302mm D:535mm

| 18.6kg

|

CR2000-010B-14TF1

| 788℃ | 10kVA

| 3-phase 380-460V 50-60Hz 12.5-15A

| 9kW 3-35 KHz duty cycle 100% | W:263mm H:302mm D:535mm

| 18.6kg |

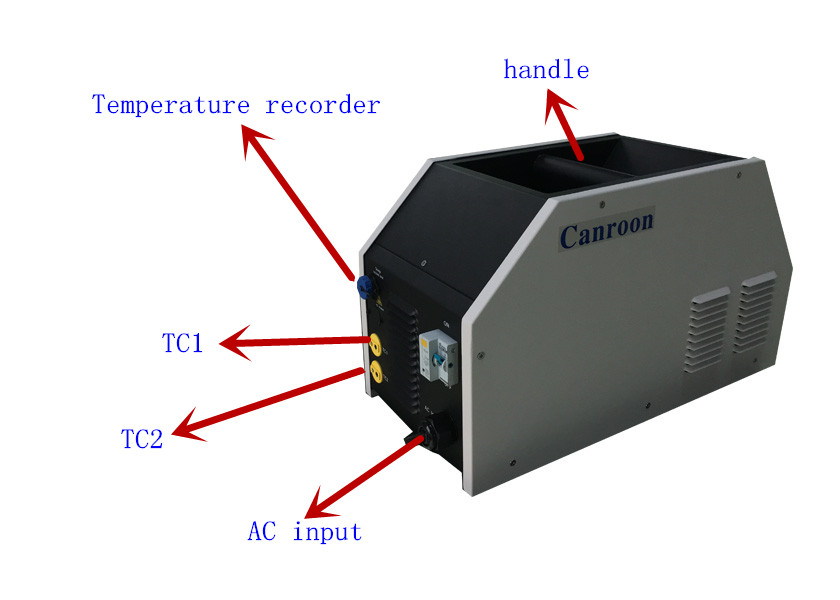

Detailed picture of air cooling post weld heat treatment induction heating machine price:

Front:

Back:

Accessaries of air cooling post weld heat treatment induction heating machine price:

We offer multiple accessaries like thermocouple, thermocouple welding machine, digital temperature-recorder, remote switchgear, output extension cable, insulation blanket, etc. Complete solution saves your time and ensures you to start work soon after received our dellivery.

Advantages of air cooling post weld heat treatment induction heating machine price:

We have display panel to show working parameters, and temperature recorder can feedback PWHT curve, you can print it.

The interface offers two basic control mode to choose including temperature control and power control. Thus brings the benefit of wide applicability and precise control.

Fault codes will display and be recorded for reference, and system will respond with protection action like shutdown once fault occurs such as open-loop output or short out.

Due to modular design, the maintance will be easy and low-cost.

Once fault occurs, induction heater will display fault code, which was detailed explained in manual book.

This uniquely energy-efficient process converts up to 90% of the expended energy into useful heat, and time-to-temperature is faster than conventional processes, reducing cycle time.

The heat is induced within the part itself by alternating electrical current, thus uniform temperature throughout the heating zone is realized.

Company information: