Zhengzhou Lanshuo Electronics Co., Ltd |

|

Verified Suppliers

|

|

| Model | KGPS-0.5T/400KW |

| Rated Power | 400kw |

| Rated Capacity | 0.5T |

| Matching transformer's capacity | 500KVA |

| Voltage | 380V, 50/60HZ |

| MF Frequency | 2000HZ |

| Medium Voltage | 750V Phase |

| DC Voltage | 500V Phase |

| DC Current | 800A Phase |

| Rated Temperature | 1600°C |

| Closed Loop Water Cooling Tower | LSN-30B |

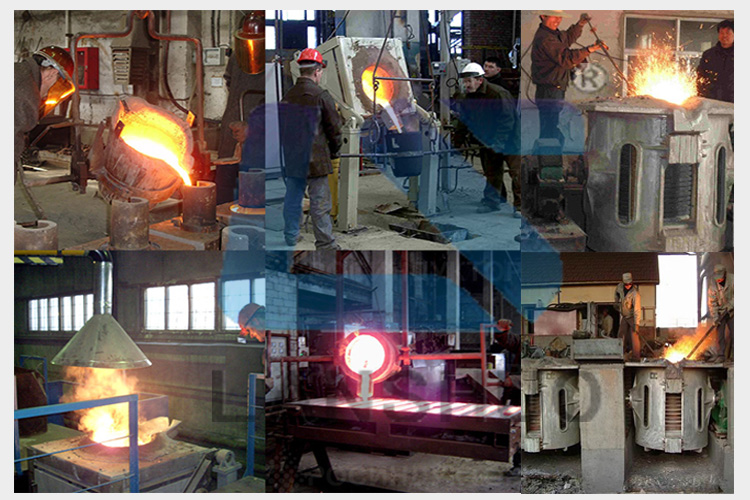

3. Large Induction Melting Furnace Application:

(1) iron, pig iron, cast iron;

(2) steel, stainless steel, cast steel, carbon steel and bearing steel;

(3) gold, silver, platinum;

(4) copper, brass, bronze;

(5) aluminum, aluminum alloy;

(6) zinc, lead, tin, magnesium, nickel, titanium.

4. Part of the melting furnace:

1). Furnace Parts: The mechanical parts of the MF furnace consisted of furnace

pot,water power introduced into the system, titling device and

other parts.

2). Furnace Ports: Furnace port including furnace shell, induction coil etc.

3). Furnace Shell:

| Main Power Cabinet | Furnace Shell | Reducer | Water Cooled Cable | Crucible Mould | Induction Coil |

|  |  |  |  |  |

5. The characteristics of the smelting furnace are as follows:

The smelting furnace uses an intermediate frequency power supply to establish an intermediate frequency magnetic field, which induces eddy currents and heat generation in the ferromagnetic material, so as to achieve the purpose of heating the material. The medium frequency electric furnace uses a 200-2500Hz medium frequency power supply for induction heating, smelting and heat preservation. The smelting furnace is mainly used for smelting carbon steel, alloy steel, special steel, and can also be used for smelting and heating of non-ferrous metals such as copper, aluminum, lead, and zinc. Small size, light weight, high efficiency, low power consumption, fast melting and heating, easy control of furnace temperature, and high production efficiency.

6. KGPS melting furnace Features:

1. The electric furnace is small in size, light in weight, high in efficiency, and low in power consumption; the temperature around the furnace is low, there is less smoke and dust, and the working environment is good;

2. The operation process is simple, the smelting operation is reliable; it is convenient to change the variety.

3. The heating temperature is uniform, the burning loss is small, and the metal composition is uniform;

4. The casting quality is good, the melting temperature is fast, the furnace temperature is easy to control, and the production efficiency is high; 5. According to its characteristics in industry, it can be called industrial furnace, electric furnace, high-frequency electric furnace, small electric furnace, and energy-saving furnace.

6. The furnace body can be dumped electrically, easy to come out, especially suitable for casting.