Zhengzhou Lanshuo Electronics Co., Ltd |

|

Verified Suppliers

|

|

| Model | KGPS-0.5T/400KW |

| Rated Power | 400kw |

| Rated Capacity | 0.5T |

| Matching transformer's capacity | 500KVA |

| Voltage | 380V, 50/60HZ |

| MF Frequency | 2000HZ |

| Medium Voltage | 750V Phase |

| DC Voltage | 500V Phase |

| DC Current | 800A Phase |

| Rated Temperature | 1600°C |

| Closed Loop Water Cooling Tower | LSN-30B |

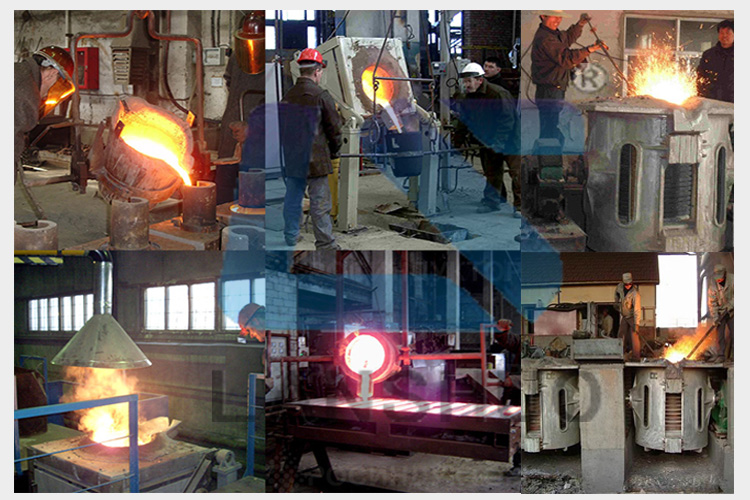

3. Large Induction Melting Furnace Application:

aluminum shell medium frequency melting furnace required little area, which is easy to operate, easy to use, and inexpensive, suitable for melting all kinds of pig iron, cast iron, scrap, iron slag, etc.

4. Part of the aluiminum shell induction melting furnace:

1). Furnace Parts: The mechanical parts of the MF furnace consisted of furnace

pot,water power introduced into the system, titling device and

other parts.

2). Furnace Ports: Furnace port including furnace shell, induction coil etc.

3). Furnace Shell:

| Main Power Cabinet | Furnace Shell | Reducer | Water Cooled Cable | Crucible Mould | Induction Coil |

|  |  |  |  |  |

5. Large Induction Melting Furnace Advantage:

Standard features of induction melting furnace:

Open furnace structure. The basic structure: with unique shock

absorber and solid magnetic yoke, two cylinder with thick wall

seamless rectangular steel tube is welded into one structure, being

safer, firm, durable, high efficient. The upper end of the

induction furnace can be disassembled to facilitate the replacement

of the coil.

Hydraulic tilting. Furnace can rotate around the pouring spout, and

tilting with proportional control, through controlling buttons of

hydraulic station and the handle of tilting control device . Its

tilting angle is vertically at 95 degrees and it can stay in any

position in the process of rotating, as well as to change titling

speed to more quicker or more slowly. It uses the manual valve

operation and double machine double pump, with remote manual

control system. Some other company only have single pump control.

Magnetic yoke. The sensor is enclosed with a magnetic yoke,

covering an area is over 65%, so the leakage is small and achieve

the maximum electrical efficiency. Compared with aluminum shell

furnaces, steel shell furnace can save nearly 5% power consumption.

Anti-fall protection device (for more than 2 ton capacity). During

the process of tilting furnace, the anti-falling protective hood

will be automatically raised to form a protective barrier to

prevent the personnel from falling.

Factory test.