Zhengzhou Lanshuo Electronics Co., Ltd |

|

Verified Suppliers

|

|

1. high frequency Induction Brazing Welding Machine Main characteristic:

Adopting MOSFGT and IGBT inverting device, tracking frequency

automatically

·High frequency, heated quickly, its power consumption is only

20%~30% of electronic tube

induction heating machine and other heating style.

·Security and reliability, the equipments have the secure voltage

and it's secure to operate

·Manual, automatic regulating automatically, it can protect itself

from over voltage, over

current,lack of water, phase fail, over hot, etc

·It has no openfire, noise and pollution, be suit for the

environmental protection and fire, improve the image of the

company.

·Recommend usage: quenching,annealing,

forging,welding,melting,shrink fit, hot cooperation etc.

2. Welding (brazes welding, silver soldering and brazing):

1. It’s mainly aims to melt the solder by heating it to a certain

temperature for the purpose of connecting to types of metals of the

same material or different materials.

2. Welding of various hardware cutting tools, such as diamond tool,

abrasive tool, drilling tool, alloy saw blade, hard alloy cutter,

milling cutter, reamer, planning tool and solid center bit.

3. Welding of various hardware mechanical gadgets, silver soldering

and brazing of metals of the same varieties, such as hardware

toilet and kitchen products refrigerating copper fitting, lamp

decoration fitting, precision mold fitting, hardware handle,

eggbeater, alloy steel and steel, steel and copper as well as

copper and copper.

4. Compound pot bottom welding is mainly applicable to the braze

welding circular, square as well as other irregular plain pot

bottom. It is also applicable to plain braze welding of other

metals.

5. Welding of heating disc of electric hot-water kettle mainly

refers to the braze welding stainless steel flat base, aluminum

sheet and tubular electric heating elements of various forms.

3. Technical Parameters of LSW-30 Induction Brazing Equipment:

| Model | LSW-30 |

| Working Voltage | 380V, 50/60HZ |

| Max input power | 30kw |

| Oscillation frequency | 25-40KHZ |

| Duty cycle | 100% |

| Cooling water flow | 25L/Min,0.15-0.2MPa |

| Weight | 48kg |

| Dimension (L*W*H ) | 690*290*600mm |

| Material | stainless steel |

| Color | support customized |

| Usage | metal heating, brazing,melting etc |

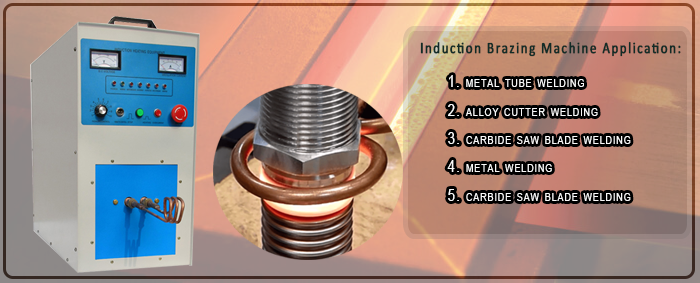

4. Main applications and features of induction brazing machine:

1) Brazing of tools, turning tools, milling cutters, etc.

2) Brazing of diamond tools, diamond circular saw blades,

thin-walled drill bits, etc.

3) Heat treatment of small parts: annealing, quenching, tempering,

preheating, hot fitting, etc.

4) Precious metals A small amount of smelting such as gold, silver,

copper, etc.

5) 1KG small amount of stainless steel material smelting;

5. Performance and characteristics of high frequency induction brazing / welding machine:

Using imported Fuji power components and high-quality components to

ensure high-quality equipment quality mall body weight, high

efficiency and energy saving

Overcurrent, overvoltage, under water, overheat protection circuit

Exquisite design, 304 stainless steel screws, 304 stainless steel

handlebars, no paint stripping, stripping phenomenon, preferred

exporter

Split type equipment: main unit, transformer consists of two parts,

the intermediate connecting cable is 2 to 6 meters long; flexible

movement can be realized without reducing the power loss of the

equipment, especially suitable for automatic production lines or

dirty environments;