Zhengzhou Lanshuo Electronics Co., Ltd |

|

Verified Suppliers

|

|

1. Features of medium frequency induction melting furnace:

1.Electromagnetic stirring will help keeping the temperature

stable, reducing impurities.

2. Easy to install and operate, no need to make foundation or any

civil work.

3. Super small size and portable, occupies less than 1.0 square

meters.

4. Power saving and environmental protection.

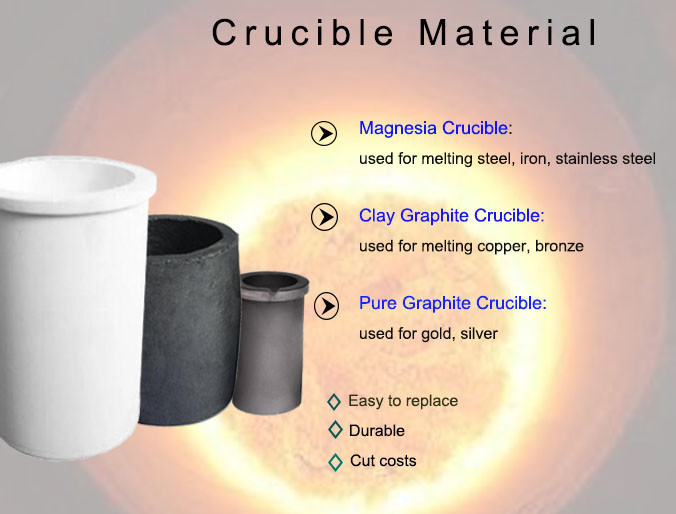

5. Using crucible: No need to make lining by refractory material as

the normal induction furnace.

6. Easy to change and melt different materials.

2. Melting Capacity of Induction Melting Furnace:

| ||||||||||||||||||||||||||||||||||||||||||||||||

3. Description of gold aluminum electric induction furnace:

Melting metals with solid state induction heating is usually

accomplised by heating the metal in a crucible made from a

non-conductive refractory meterial. The charge of metal within the

crucible is melted down to liquid form.

This process is commonly used to produce high quality steels and non ferrous alloys for casting operations. The liquefied metal is poured into a cavity having the desired shape. The metal solidifies with a minimum of shrinkage,after which the mold is removed to reveal a finished, machinable product. For example:melting for gold, silver, copper, aluminum, stainless steel and other metal materials.

4. Scope of application gold melting furnace / aluminum melting

furnace

Apply to: jewelry casting, precious metal purification, copper smelting,

molten aluminum, slag smelting, metal composition analysis,

smelting process test.

There are four kinds of melting furnace as below.

1.smelting for precious metals, such as gold, sliver, copper scrap

melting;

2.smelting for iron, steel, copper, platinum, aluminum and other

noble metals;

3.smelting for ferrous and non ferrous metals;

4.smelting for alloys;

5.smelting for metal rods;

6.other smelting work for metal product.

5. Main technical parameters of LSZ series induction melting furnace:

| Model | Power | Input current | Voltage | Oscillation frequency | Connect- ing wire | Control switch |

| LSZ-15 | 15kw | 18A | 3-phase 380 V, 50/60 Hz | 1-15KHz | 10mm2 | 3*40A |

| LSZ-25 | 25kw | 36A | 10mm2 | 3*60A | ||

| LSZ-35 | 35kw | 57A | 16mm2 | 3*80A | ||

| LSZ-45 | 45kw | 80A | 35mm2 | 3*120A | ||

| LSZ-70 | 70kw | 110A | 50mm2 | 3*150A | ||

| LSZ-90 | 90kw | 140A | 75mm2 | 3*225A | ||

| LSZ-110 | 110kw | 160A | 90mm2 | 3*225A | ||

| LSZ-160 | 160kw | 240A | 120mm2 | 3*300A |

6. Stainless Steel / Bronze Induction Melting Furnace Feature:

1. 100% duty cycle , 24hours continuous working ability at maximum

power.

2. High efficiency and energy saving:,a high power factor and power

efficiency within the scope of full power.

3. With wide frequency range from 1-20KHZ automatic tracking

ability, no need adjustment at scene.

4. Constant output voltage or power control modes are alternative;

5 Full display of output power, output frequency, output voltage

and current.

6. simple operation: operate can be learned in a few minutes.

7. simple installation: connect the machine to 3phase 380VAC and

cooling water only.

8. timer can be chosen to preset and adjusted the heating time,

heating power, retaining time, retaining power respectively to

control the heating curve and heating temperature.