Zhengzhou Lanshuo Electronics Co., Ltd |

|

Verified Suppliers

|

|

Medium frequency induction melting furnace uses an medium frequency

power supply to establish an medium frequency magnetic field, which

induces eddy currents and heat generation in the ferromagnetic

material to achieve the purpose of heating material.

2. Technical Parameter of Large Induction Melting Furnace:

| Model | KGPS-01T/100KW |

| Rated Power | 100kw |

| Rated Capacity | 0.1T |

| Matching transformer's capacity | 150KVA |

| Voltage | 380V, 50/60HZ |

| MF Frequency | 2000HZ |

| Medium Voltage | 750V Phase |

| DC Voltage | 500V Phase |

| DC Current | 200A Phase |

| Rated Temperature | 1600°C |

| Closed Loop Water Cooling Tower | LSN-10B |

3. Large Induction Melting Furnace Application:

What are the different applications that induction melting furnaces can be used for?

Investment casting. Induction melting is often used for investment casting because they come in a wide variety of air and vacuum furnaces. These furnaces work great for nearly all metals.

Precious metals melting. Steel is precious for many, but induction furnaces can also be

used to melt precious metals such as platinum group metals. This

allows them to be refined and used for jewelry manufacturing.

Copper melting. Induction furnaces can be used to melt custom castings or casting

large bronze structures. They’re built to provide the melting you

need for most copper applications with low metal loss and precise

temperature control.

Alloy manufacturing. Induction furnaces are popularly used in alloy manufacturing for

optimal uniformity and flexibility. Those in alloy manufacturing

companies can count on induction furnaces to provide them with the

correct amount of induction stirring each and every time so every

product comes out exactly the same.

Aluminum melting. Aluminum melting is another popular application used for induction

melting. Because induction furnaces are energy efficient, they’re

considered optimal for converting alumina into pure aluminum and

then into aluminum alloys. This is because this process consumes a

lot of energy and so the more energy that can be saved the better.

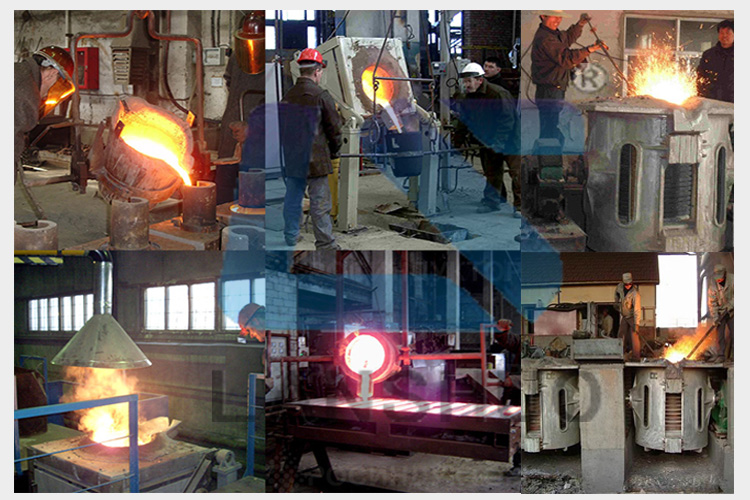

4. Part of the melting furnace:

1). Furnace Parts: The mechanical parts of the MF furnace consisted of furnace

pot,water power introduced into the system, titling device and

other parts.

2). Furnace Ports: Furnace port including furnace shell, induction coil etc.

3). Furnace Shell:

| Main Power Cabinet | Furnace Shell | Reducer | Water Cooled Cable | Crucible Mould | Induction Coil |

|  |  |  |  |  |