Guangzhou Zhenhui Machinery Equipment Co., Ltd |

|

Verified Suppliers

|

|

Undercarriage Spare Parts Sprocket Rim For HITACHI Excavator

EX220 EX300 EX300-1

Specification:

| Product name | Sprocket Rim For HITACHI Excavator |

| Model NO. | EX120 EX220 EX300 EX300-1 EX300-2 EX400 ZAX200 ZAX330 |

| Material | steel alloy |

| Surface hardness | HRC45-55 |

| Technique | Forging casting |

Track link and shoe assy, Track roller, Carrier roller, Idler, Sprocket, Track link guide, Track Adjuster assy, etc.

Applicable excavator models

| Excavator sprocket list | ||||||||

| EX40-1 | EX40-2 | EX55 | EX60 | EX60-2 | EX60-3 | EX60-5 | EX70 | EX75 |

| EX100 | EX110 | EX120 | EX120-1 | EX120-2 | EX120-3 | EX120-5 | EX130-1 | EX200-1 |

| EX200-2 | EX200-3 | EX200-5 | EX220-3 | EX220-5 | EX270 | EX300 | EX300-1 | EX300-2 |

| EX300-3 | EX300-5 | EX300A | EX330 | EX370 | EX400-1 | EX400-2 | EX400-3 | EX400-5 |

| FX450 | 7AX30 | 7AX55 | ZAX200 | ZAX200-2 | ZAX330 | 7AX450-1 | 7AX450-3 | 7AX450-5 |

| ZX110 | ZX120 | ZX200 | ZX200 | ZX200-1 | ZX200-3 | ZX200-5g | ZX200LC-3 | ZX210 |

| ZX210-3 | ZX210-3 | ZX210-5 | ZX225 | ZX240 | ZX250 | ZX270 | ZX30 | ZX330 |

| ZX330 | ZX350 | ZX330C | ZX450 | ZX50 | ||||

| PC20-7 | PC30 | PC30-3 | PC30-5 | PC30-6 | PC40-7 | PC45 | PC45-2 | PC55 |

| PC120-6 | PC130 | PC130-7 | PC200 | PC200-1 | PC200-3 | PC200-5 | PC200-6 | PC200-7 |

| PC200-8 | PC210-6 | PC220-1 | PC220-3 | PC220-6 | PC220-7 | PC220-8 | PC270-7 | PC202B |

| PC220LC-6 | PC220LC-8 | PC240 | PC300 | PC300-3 | PC300-5 | PC300-6 | PC300-7 | PC300-7K |

| PC300LC-7 | PC350-6/7 | PC400 | PC400-3 | PC400-5 | PC400-6 | PC400IC-7 | PC450-6 | PC450-7 |

| PC600 | PC650 | PC750 | PC800 | PC1100 | PC1250 | PC2000 | ||

| E2008 | E200-5 | E320D | E215 | E320DL | E324D | E324DL | E329DL | E300L |

| E320S | E320 | E320DL | E240 | E120-1 | E311 | E312B | E320BL | E345 |

| E324 | E140 | E3008 | E330C | E120 | E70 | E322C | E322B | E325 |

| E325L | E330 | E450 | CAT225 | CAT312B | CAT315 | CAT320 | CAT320C | C.AT320BL |

| CAT330 | CAT322 | CAT245 | CAT325 | CAT320L | CAT973 | |||

| D3 | D3C | D4 | D4D | D4H | D5M | D5H | D6 | D6D |

| D6M | D6R | D6T | D7 | D7H | D7R | D8 | D8N | D8R |

| D9R | D9N | D9G | D10 | |||||

| SK120-6 | SK120-5 | SK210-8 | SK210LC-8 | SK220 | SK220-1 | SK220-3 | SK220-5/6 | SK200 |

| SK200 | SK200 | SK200-3 | SK200-6 | SK200-8 | SK200-5/6 | SK60 | SK290 | SK100 |

| SK230 | SK250 | SK250-8 | SK260LC-8 | SK300 | SK300-2 | SK300-4 | SK310 | SK320 |

| SK330-8 | SK330 | SK350LC-8 | SK235SR | SK450 | SK480 | SK30-6 | ||

| SH120 | SH120-3 | SH200 | SH210-5 | SH200 | SH220-3 | SH220-5/7 | SH290-3 | SH350-5/7 |

| SH220 | SH280 | SH290-7 | SH260 | SH300 | SH300-3 | SH300-5 | SH350 | SH60 |

| SH430 | ||||||||

| DH200 | DH220-3 | DH220 | DH220S | DH280-2 | DH280-3 | DH55 | DH258 | DH130 |

| DH370 | DH80 | DH500 | DH450 | DH225 | ||||

| R60-5 | R60-7 | R60-7 | R80-7 | R200 | R200-3 | R210 | R210 | R210-9 |

| R210LC | R210LC-7 | R225 | R225-3 | R225-7 | R250 | R250-7 | R290 | R290LC |

| R290LC-7 | R320 | R360 | R954 | |||||

| EC160C | EC160D | EC180B | EC180C | EC180D | EC210 | EC210 | EC210B | EC240B |

| EC290 | EC290B | EC240 | EC55 | EC360 | EC36B | EC380D | EC460 | EC460B |

| EC460C | EC700 | EC140 | EC140B | EC160B | ||||

| HD512 | HD1430 | HD 512IⅢ | HD 820 | HD820R | HD1430Ⅲ | HD700VI | HD 1250VI | HD250SE |

| HD400SE | HD550SE | HD1880 | ||||||

| DX225 | DX225LCA | DX258 | DX300 | DX300LCA | DX420 | DX430 | ||

The manufacturing process of excavator driving teeth usually includes the following steps:

1. Material selection: Use high-strength alloy steel.

2. Forging: The raw materials are heated to a certain temperature and forged to obtain the desired shape.

3. Heat treatment: Improve the hardness and wear resistance of the teeth through annealing, quenching and other processes.

4. Machining: including turning, milling, grinding, etc. to ensure dimensional accuracy and surface quality.

5. Tooth shape processing: Use gear processing machine tools to process precise tooth shapes.

6. Surface treatment: such as quenching, carburizing, etc., to improve surface hardness and wear resistance.

7. Testing: Test the size, shape, hardness, etc. of the teeth to ensure they meet quality standards.

8. Assembly: Install the drive teeth into the excavator’s drive system.

During the production process, you need to pay attention to the following points:

9. Strictly control material quality and processing accuracy to ensure the performance and life of the driving teeth.

10. Follow relevant standards and specifications to ensure product quality.

11. Perform regular maintenance and optimization of processing equipment and processes to improve production efficiency and product quality.

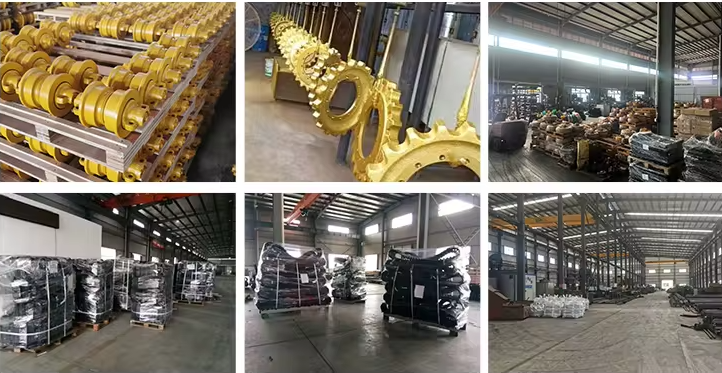

Our warehouse and factory

Packing & Delivery:

Shipping methods

BY EXPRESS, AIR, SEA

GOODS WILL BE SHIPPED WITHIN 5 DAYS AFTER PAYMENT RECEIVED.

If you can provide the appropriate model and part number, we can provide the appropriate product. Online quotation from professional and experienced salespersons

Regardless of the order size, as long as the customer places an order, we will provide export services

Due to the wide variety, we are working hard to improve it. If you do not find the parts you need in our store, please contact customer service with the pictures.