Guangzhou Zhenhui Machinery Equipment Co., Ltd |

|

Verified Suppliers

|

|

Main Valve /Service Valve R200 R210 R215 R220 R225-7 R225-9 Excavator Accessories Relief Valve For Hyundai

About Products:

The following are some ways to determine whether the excavator safety relief valve is working properly:

1. Observe the system pressure: Use a pressure gauge to measure the system pressure to see if it is within the normal range.

2. Check the pressure relief: when the system pressure reaches the set value, observe whether there is pressure relief.

3. Listen for the sound: When operating normally, the pressure relief valve may make a specific sound when it relieves pressure.

4. Check for leaks: Look around the pressure relief valve for signs of leaks.

5. Observe the working performance: Pay attention to whether the working performance of the excavator is normal, such as whether the movement is smooth, etc.

6. Compare devices of the same model: Compare with devices of the same model that are working properly.

7. Check the valve core and valve body: Make sure the valve core and valve body are not worn or damaged.

8. Test multiple times: Test multiple times under different working conditions.

9. Check the pressure regulating device: Confirm whether the pressure regulating device is normal.

10. Check the fault indicator light: If there is a relevant fault indicator light, check its status.

11. Check the hydraulic oil temperature: Excessively high temperatures may indicate a problem with the pressure relief valve.

12. Check other components of the hydraulic system: eliminate the

possibility of failure of other components.

If you suspect there is a problem with the pressure relief valve,

it is recommended that it be inspected and repaired by professional

maintenance personnel.

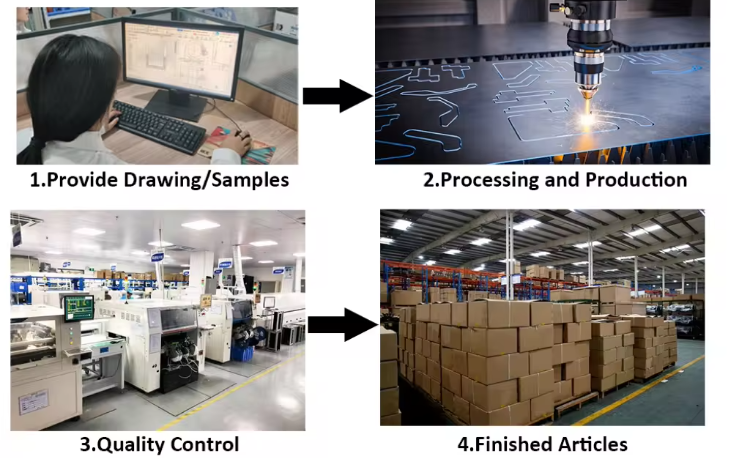

Production processes:

The manufacturing process of excavator safety relief valve usually includes the following steps:

1. Material selection: Choose high-strength, corrosion-resistant materials, such as alloy steel.

2. Design and Drawing: Carry out detailed design and drawings according to technical requirements.

3. Mechanical processing:

• Valve body processing: including drilling, milling, etc.

• Valve core machining: ensuring accuracy and surface quality.

4. Heat treatment: Improve the strength and wear resistance of parts.

5. Grinding and polishing: Make the surface smooth and reduce leakage.

6. Assembly:

• Install the valve core: ensure flexible movement.

• Assembling other parts: strictly follow the process requirements.

7. Test:

• Pressure Test: Verify the operating pressure range of the pressure relief valve.

• Seal test: Check for leaks.

8. Quality inspection: ensure compliance with relevant standards.

9. Surface treatment: such as electroplating, spraying, etc., to improve anti-corrosion performance.

10. Packaging and shipment: Use appropriate packaging to prevent damage during transportation.

During the entire production process, strict quality control is

required to ensure the stable and reliable performance of the

pressure relief valve. At the same time, follow relevant standards

and specifications to meet safety requirements.

Our company:

Why choose us

We would like to establish a long time strategy cooperation relationship with our customers,, support and train the potential customer to be our agent at each country and region all over the world.

We would like to establish a long time strategy cooperation relationship with our customers,, support and train the potential customer to be our agent at each country and region all over the world.

Packing & Delivery

Delivery way available with Express, Air or Ocean

Powerful parts store

If you can provide the appropriate model and part number, we can

provide the appropriate product. Online quotation from professional

and experienced salespersons

Regardless of the order size, as long as the customer places an

order, we will provide export services.