Cylindrical Spherical Outside And Inside Surface Portable Hardness

Tester. Metal Durometer Hardness Tester Portable

Main Advantages

- Large screen (128×64 dot matrix LCD), showing all functions and

parameters.

- Can test at any direction

- Big measuring range. It can measure the hardness of all

metallic materials. Direct display of hardness scales Covered

common scales (HV, HB, HRC, HRB, HRA, HS).

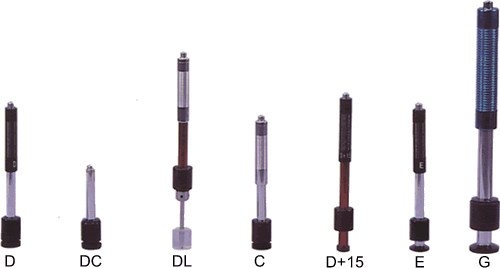

- Seven impact devices are available for special application.

Automatically identify the type of impact devices.

- Big capacity memory could store 600 groups (Relative to

average times32~1 ) information including single measured value,

mean value, testing data, impact direction, impact times, material

and hardness scale etc.

- Upper and lower value limit can be preset. It will alarm

automatically when the result value exceeding the limit.

- Battery indicates the rest capacity of the battery and the

charge status.

- User calibration function for special material calibration.

- Auto power off function

- Excellent after-sale service system for high quality products---two

years’ guarantee and all life maintenance. Easy to buy and

comfortable to use.

- Hermetically sealed metal shell, solid and durable, has excellent

resistance to vibration, shock and electromagnetic interference

ability.

- With USB or RS232 interface, convenient to connect with PC.

- Printer can be separated from main unit and copies of testing

result can be printed as required.

- Narrow testing space needed.

- 14 kinds of supporting rings for shaped material testing, such

as Cylindrical & Spherical Outside And Inside

Surface

Main Application

- Die cavity of molds

- Bearings and other parts

- Failure analysis of pressure vessel, steam generator and other

equipment

- Heavy work piece

- The installed machinery and permanently assembled parts

- Testing surface of a small hollow space

- Material identification in the warehouse of metallic materials

- Rapid testing in large range and multi-measuring areas for

large-scale work piece.

Specifications of hardness tester RHL50

Hardness scale

HL, HB, HRB, HRC, HRA, HV, HS

Memory

48~600 groups (impact times: 32~1)

Measuring

range

HLD(170~960)See below table 1 and table 2

Accuracy

±6HLD (760±30HLD) error of displayed value

6HLD (760±30HLD) repeatability of displayed value

Standard Impact

Device

D

Optional Impact

Devices

DC/D+15/G/C/DL

Max. Workpiece Hardness

996HV(For Impact Devices D/DC/DL/D+15/C)

646HB(For Impact Device G)

Min. Radius of Workpiece (convex/concave) Rmin = 50mm

(with special support ring Rmin= 10mm)

Min. Workpiece weight

2~5kg on stable support

0.05~2kg with compact coupling

Min. Workpiece thickness

5mm (Impact Devices D/DC/DL/D+15)

1mm (Impact Device C)

10mm (Impact Device G)

Min. thickness of hardened surface 0.8mm

Power

AA battery

Continuous Working time approx.

100 h (no back light off)

Charging time

2-3.5 h

Operating temperature

0~40℃

Relative humidity

≤90%

Overall dimensions

152×84×34mm (main unit)

Weight

0.3kg (main unit)

Standard delivery of portable hardness tester RHL50

●Main unit RHL50

●Impact Device type D

●Test block with HLD value

●Charger

●Nylon brush

●Small supporting ring

●DataView Software

●USB&RS232 Communication cable

●Calibration Certificate

●Instruction manual

●Warranty card

●Carrying case

Optional accessories of portable hardness tester RHL50

●Optional Impact Devices DC/D+15/G/C/DL

●Normal and special type support rings (14pcs)

●Other test block (High, medium and low value))

●Printer

●Impact body

●Impact ball tip

●Tools for changing the ball tip

Testing range see table 1 and table 2.

Table 1

Material | Hardness method | Impact device |

D/DC | D+15 | C | G | E | DL |

Steel and cast steel | HRC | 17.9~68.5 | 19.3~67.9 | 20.0~69.5 | | 22.4~70.7 | 20.6~68.2 |

HRB | 59.6~99.6 | | | 47.7~99.9 | | 37.0~99.9 |

HRA | 59.1~85.8 | | | | 61.7~88.0 | |

HB | 127~651 | 80~638 | 80~683 | 90~646 | 83~663 | 81~646 |

HV | 83~976 | 80~937 | 80~996 | | 84~1042 | 80~950 |

HS | 32.2~99.5 | 33.3~99.3 | 31.8~102.1 | | 35.8~102.6 | 30.6~96.8 |

Hammered steel | HB | 143~650 | | | | | |

Cold work tool steel | HRC | 20.4~67.1 | 19.8~68.2 | 20.7~68.2 | | 22.6~70.2 | |

HV | 80~898 | 80~935 | 100~941 | | 82~1009 | |

Stainless steel | HRB | 46.5~101.7 | | | | | |

HB | 85~655 | | | | | |

HV | 85~802 | | | | | |

Gray cast iron | HRC | | | | | | |

HB | 93~334 | | | 92~326 | | |

HV | | | | | | |

Nodular cast iron | HRC | | | | | | |

HB | 131~387 | | | 127~364 | | |

HV | | | | | | |

Cast aluminum alloys | HB | 19~164 | | 23~210 | 32~168 | | |

HRB | 23.8~84.6 | | 22.7~85.0 | 23.8~85.5 | | |

Brass(copper-zinc alloys) | HB | 40~173 | | | | | |

HRB | 13.5~95.3 | | | | | |

Bronze (copper-aluminum/copper-tin alloys) | HB | 60~290 | | | | | |

Wrought copper alloys | HB | 45~315 | | | | | |

Table 2

No. | Material | HLD | Strength σb(Mpa) |

1 | Mild steel | 350~522 | 374~780 |

2 | High-carbon steel | 500~710 | 737~1670 |

3 | Cr steel | 500~730 | 707~1829 |

4 | Cr-V steel | 500~750 | 704~1980 |

5 | Cr-Ni steel | 500~750 | 763~2007 |

6 | Cr-Mo steel | 500~738 | 721~1875 |

7 | Cr-Ni-Mo steel | 540~738 | 844~1933 |

8 | Cr-Mn-Si steel | 500~750 | 755~1993 |

9 | Super strength steel | 630~800 | 1180~2652 |

10 | Stainless steel | 500~710 | 703~1676 |

Function:

On-line measuring management

Various function keys of data test, store, read, delete, clear,

print, input and output to excel etc.

PC Software sample

Key words:Hardness Tester, Leeb Hardness Tester, Portable Hardness

Tester, Portable Hand Held Leebs Metal Hardness Testers, Portable,

Hardness Testers, hardness testing equipment, hardness testing

machine, ndt, non destructive testing, ndt testing, impact device,

Leebs, ASTM Standards, HRC, HRB, HRA, HB, HV, HS, HLD, hardness

values, DIN 53505, ASTM D2240, ISO 7619