Henan HTX Group Co., Ltd. |

|

Verified Suppliers

|

|

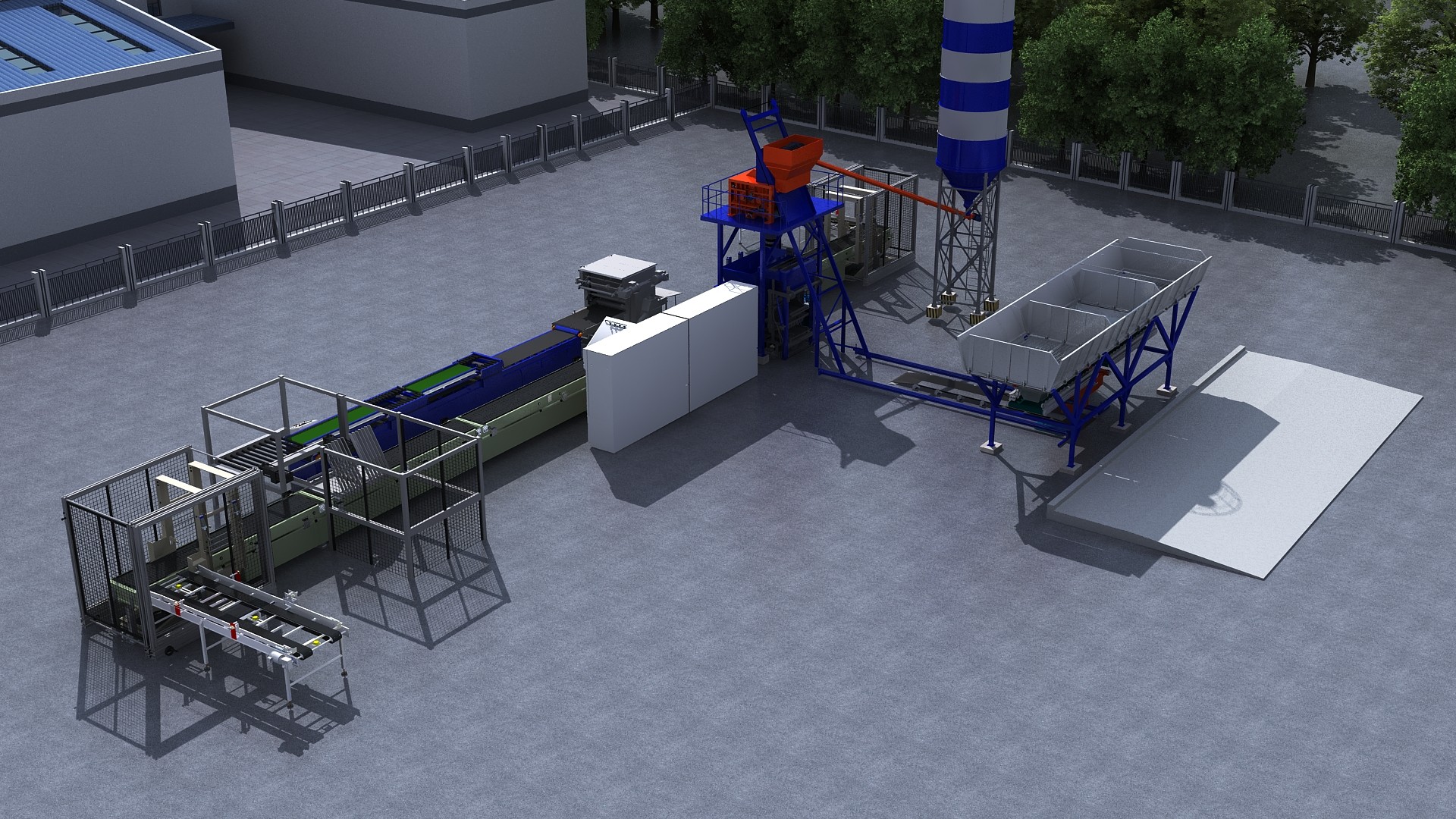

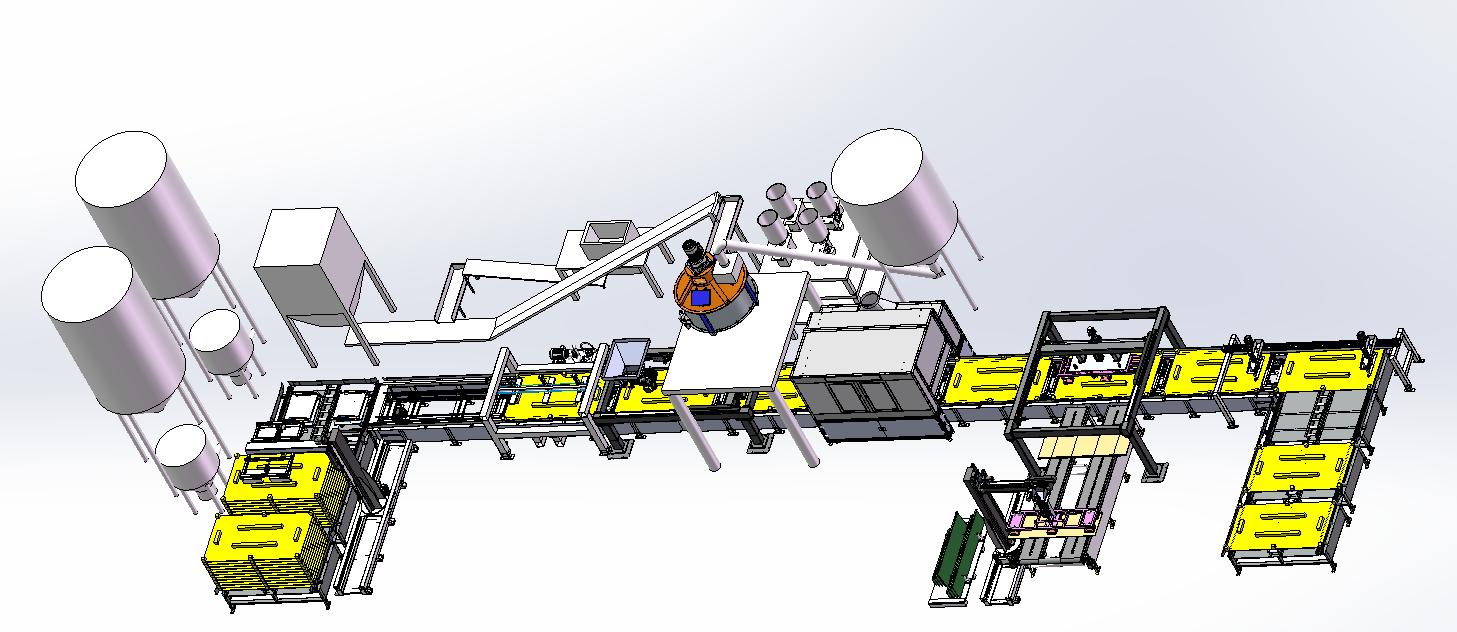

Wet Pre Cast Concrete Sandstone Colour Sleeper Machine Kerb Stone Manufacturing Machine

The production process starts with the concrete mixing stage. A concrete mixer is used to combine cement, aggregates (such as sand, gravel, or crushed stone), water, and color additives. The color additives are typically in the form of pigments specifically designed to achieve a sandstone color.Specialized moulds are used to shape the concrete mixture into sleeper units. These moulds are designed to replicate the desired dimensions and appearance of sandstone. The moulds can be made from rubber, fiberglass, or other materials and may have surface textures to mimic the natural texture of sandstone.The colored concrete mixture is poured into the moulds, ensuring that it fills all the desired areas and details. The concrete should be properly compacted to remove any air voids and ensure the structural integrity of the sleepers.After pouring, the concrete needs to cure and gain strength. The curing time may vary depending on the specific concrete mix and environmental conditions. Curing can be achieved through various methods, such as air curing, steam curing, or the use of curing compounds.Once the concrete has cured sufficiently, the moulds are removed, revealing the sandstone-like appearance of the sleepers. Care should be taken during demoulding to avoid damaging the concrete.For the most up-to-date information on available machinery and technologies specifically designed for producing concrete sleepers with a sandstone appearance, I would recommend consulting with industry professionals or manufacturers specializing in concrete products.

Specification:

| Name | Model | Specification | Size(mm) | Power(Kw) | Capacity(m2/day) | Weight(Kg) |

| Wet Cast Machinery | HTX-P-01 | Hydraulic driving;Auto feeding; vibrating and timing feeding | 7000*1000*1800 | 12.7 | 1000-1500 | 2000 |

| Wet Cast Machinery | HTX-P-02 | Chain drived;Auto feeding,auto vibration | 8000*1100*1600 | 4.05 | 800-1000 | 1500 |

Applications

Wet cast machinery, is suitable for different silicone molds,

rubber molds and plastic molds, size range from 200*200mm to

1500*1500mm, available for producing the artificial stone both for

paving tile molds, 3D wall molds, wall panel molds, roadside stone

molds, retaining wall molds, wall cap molds, etc.

Support and Services

Wet Cast Machinery technical support and services include: