Henan HTX Group Co., Ltd. |

|

Verified Suppliers

|

|

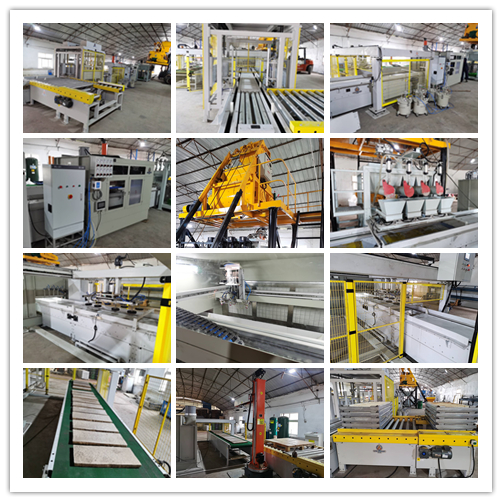

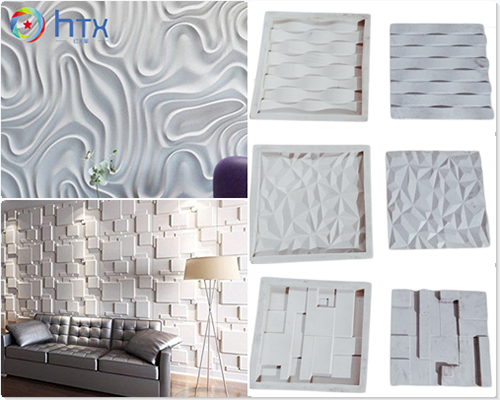

The Wall Panel Production Line is an artificial stone production line designed to produce concrete dosing system with multi-function wet casting doser machine production line. It is easy to operate and features a road edge stone making machine, artificial stone manufacturing machine and wet cast machinery. This product line is perfect for producing quality artificial stone and stone products with quick and easy operation. The Wall Panel Production Line is reliable, durable and efficient, making it an ideal choice for stone product manufacturing.

| Parameter | Value |

|---|---|

| Application | Interior And Exterior |

| Advantage | Multi Function Wet Casting Doser Machine Production Line |

| Feature | Easy To Operate |

| Product Name | Wall Panel Production Line, Retaining Block Making Machine, Kerb Stone Making Machine |

| Operation Mode | Automatic |

| Function | Producing Artificial Stone |

| Type | Stone Product Line, Artificial Stone Product Line |

| Dimension(L*W*H) | 1500*1300*2500cm |

Brand Name: HTX

Model Number: HTX-P-01

Place of Origin: HENAN

Feature: Easy To Operate

Application: Interior And Exterior

Product Name: Concrete Dosing System

Operation Mode: Automatic

Function: Producing Artificial Stone

The HTX-P-01 Concrete Dosing System is a revolutionary wall panel production line. It is designed with an automatic operation mode that makes it easy to operate. It is suitable for both interior and exterior applications, such as kerb stone making and artificial stone making. This wall panel production line is built with a unique concrete dosing system that is capable of producing high-quality artificial stones. This system is ideal for large-scale production and is capable of meeting the demands of the modern market.

The HTX-P-01 Concrete Dosing System is perfect for those who are looking for an efficient and cost-effective production line. This wall panel production line is designed to provide maximum efficiency and performance. It is capable of producing a wide range of artificial stones, making it suitable for various interior and exterior applications. With its easy operation, this production line is capable of producing high-quality artificial stones at an economical price.

The HTX-P-01 Concrete Dosing System is designed to meet the needs of the modern market. This wall panel production line is capable of producing a wide range of artificial stones, making it suitable for various interior and exterior applications. It is also capable of producing high-quality artificial stones at an economical price. Moreover, this production line is easy to operate and provides maximum efficiency and performance.

HTX-P-01 Wall Panel Production Line has all the advantages of a multi-function wet casting doser machine production line. It is easy to operate, with an automatic operation mode. It is specifically designed to produce artificial stone, such as kerb stone making machine, artificial stone manufacturing machine, and kerb stone making machine. It has a dimension of 1500*1300*2500cm, and the Brand Name is HTX.