Henan HTX Group Co., Ltd. |

|

Verified Suppliers

|

|

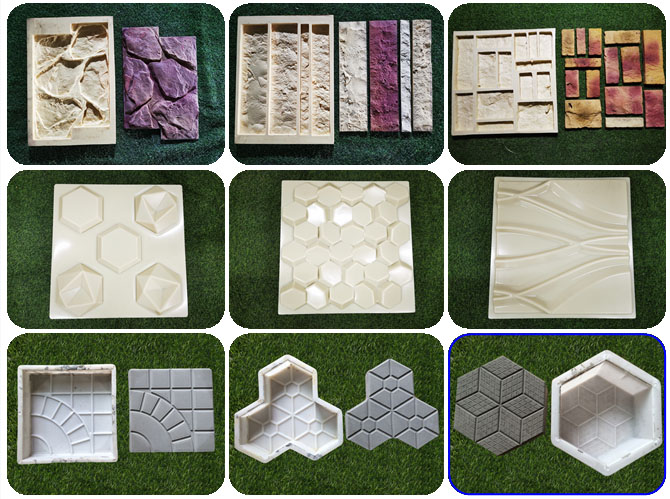

Wet Cast Machinery is an advanced and highly efficient machinery used for artificial stone production line, 3D wall panel production line, Concrete Dosing system, Automated Concrete Batching Plant, and other applications. It is designed to provide outstanding accuracy, speed, power, and durability. This machinery features a robust construction and high-precision components to ensure long-term performance and reliability. Its compact design and versatile operation make it an ideal choice for various production needs. The machinery is equipped with advanced sensors, controllers, and motors to ensure precise and reliable operation. It is capable of handling a wide variety of materials with excellent accuracy and speed. In addition, it offers long-term durability with minimal maintenance requirements. Wet Cast Machinery is the perfect choice for businesses looking for a reliable and efficient production system.

| Name | Model | Specification | Size (mm) | Power (Kw) | Capacity (m2/day) | Weight (Kg) |

|---|---|---|---|---|---|---|

| Artificial stone production line | HTX-P-01 | Hydraulic driving;Auto feeding; vibrating and timing feeding | 7000*1000*1800 | 12.7 | 1000-1200 | 2000 |

| Wet Cast Machinery | HTX-P-01A | Full Auto,timing feeding and vibration, weighing system; | 12000*1000*2000 | 9.1 | 800-1000 | 2000 |

HTX Wet Cast Machinery is the perfect solution for all your needs in veneer stone production line, 3D wall panel production line, and floor tile making machine. It is crafted with high power, and features an automatic operation with a frequency of 50 Hz. It has a size of 7000*1000*1800mm and provides accurate results with its high accuracy.

HTX Wet Cast Machinery's place of origin is in Henan, and it is renowned for being a reliable and efficient product. It is equipped with the latest technology, making it ideal for all your production line needs. Whether you are looking for veneer stone production line, 3D wall panel production line, or floor tile making machine, you can be sure that HTX Wet Cast Machinery is the perfect solution for all your needs.

It is no surprise that HTX Wet Cast Machinery is the go-to product for all your production line needs. It is durable, reliable, and efficient, and it is crafted with the latest technology. With its high power and accuracy, you can be sure that you are getting the best out of your production line.

For all your production line needs, look no further than HTX Wet Cast Machinery. It is the perfect solution for veneer stone production line, 3D wall panel production line, and floor tile making machine.

Brand Name: HTX

Place of Origin: HENAN

Durability: High

Speed: High

Size: 7000*1000*1800mm

Type: Wet Cast Machinery

Motor: High-Performance

This Wet Cast Machinery from HTX is a high-performance machine with superior durability, excellent speed and a size of 7000*1000*1800mm. It is especially designed for the production of veneer stone and is equipped with a Concrete Dosing system for precise and efficient operation.

Wet Cast Machinery offers a wide range of technical support and service for its products. Our team of qualified engineers provides professional advice and assistance in installing, operating, and maintaining the machines. Our team is available to answer any questions you may have and provide solutions to any problems that may arise. We also offer regularly scheduled maintenance to ensure optimal performance from your machine. We also provide spare parts and replacement parts for any part that may need replacing. In addition, we provide training and instruction on how to safely use and operate the machines.

Wet Cast Machinery Packaging and Shipping:

The wet cast machinery is packaged in custom wooden crates, which are constructed to safely hold the machinery during shipping. All the crates are stamped with the "Fragile" label and are reinforced with additional strapping for extra security. The crates are also waterproofed to ensure that the machinery arrives in good condition.

The wet cast machinery is shipped via air freight or sea freight, depending on the destination. We provide tracking information and insurance for all shipments to ensure that the machinery is delivered safely and on time.